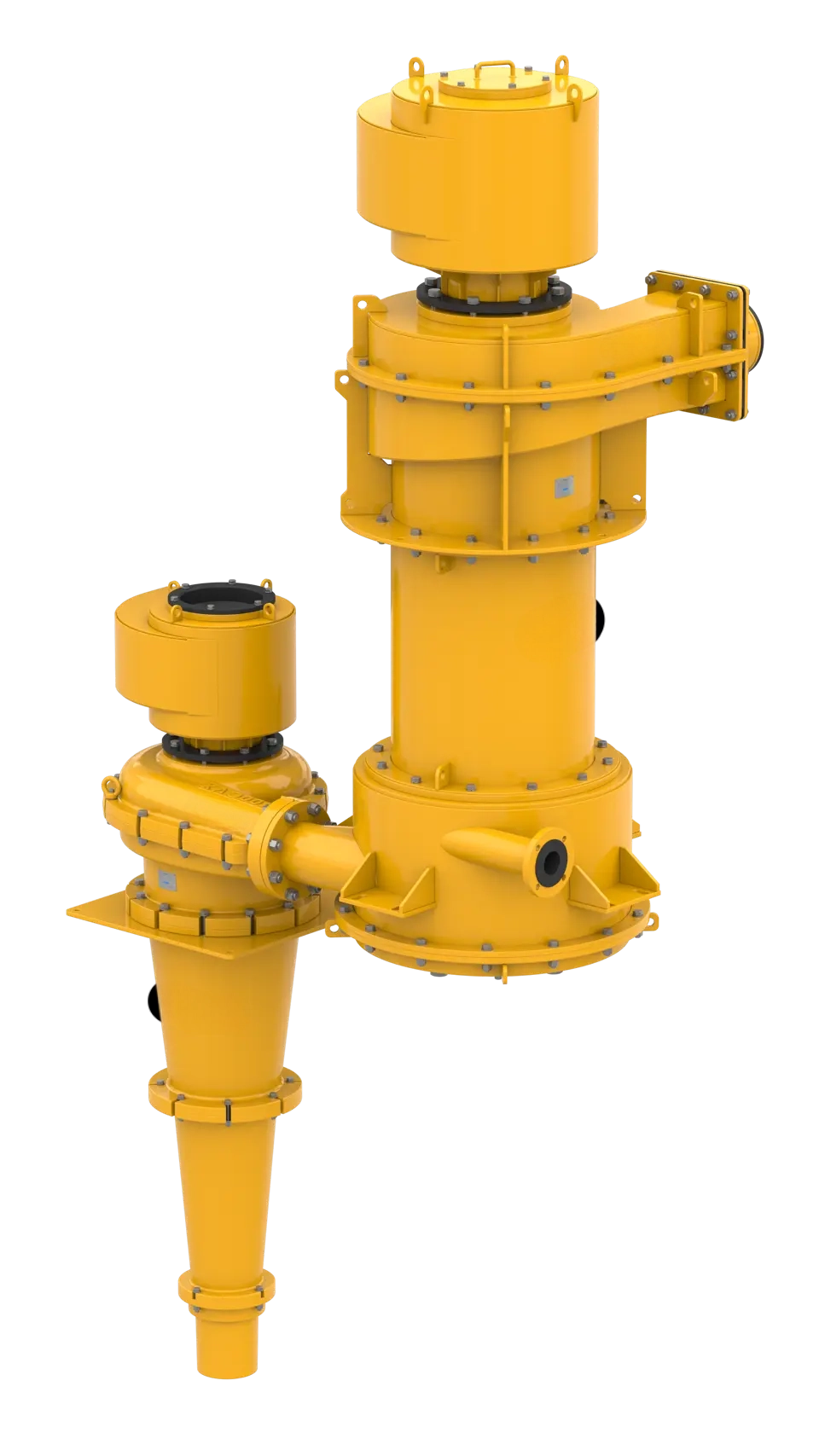

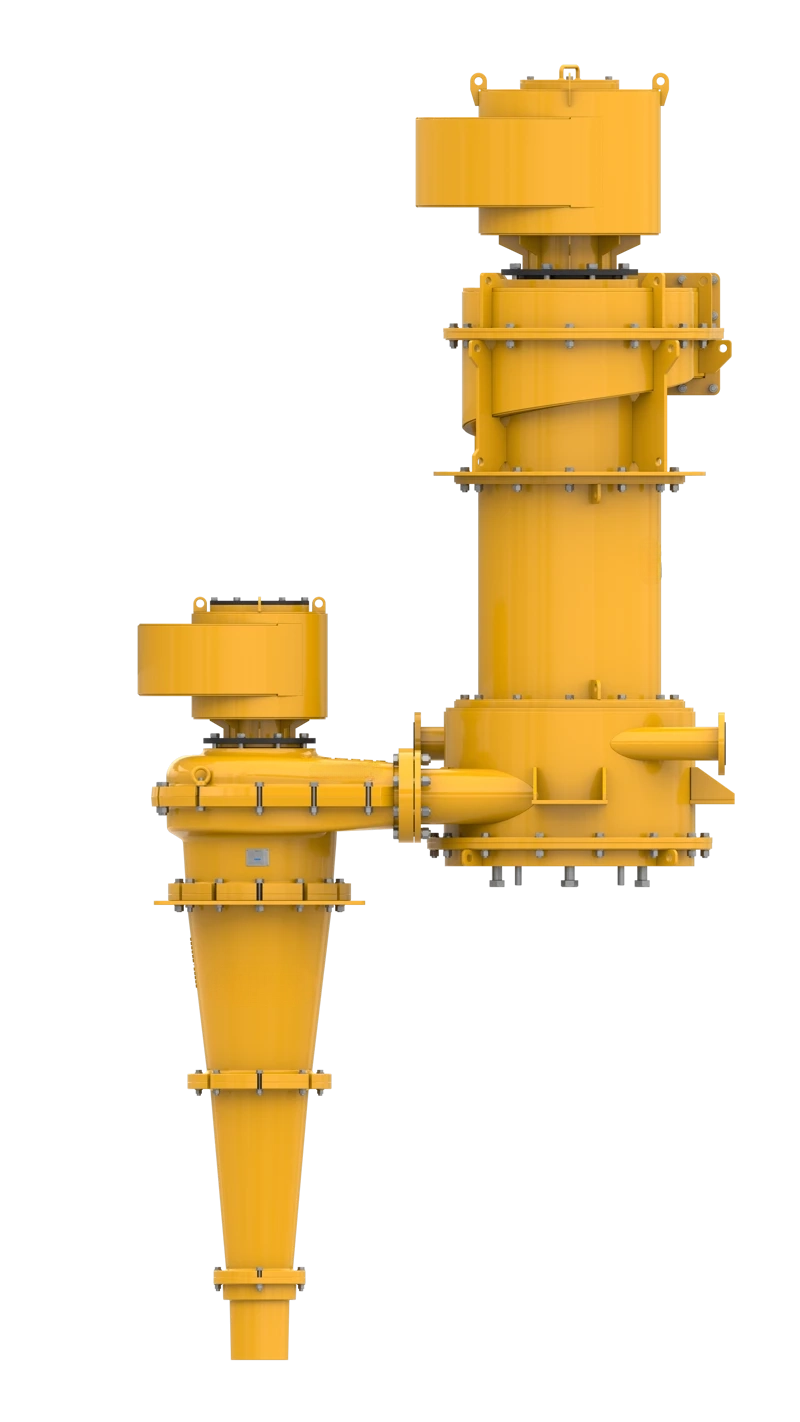

DE Series Dual-Stage Hydrocyclones

DE Series Dual-Stage Hydrocyclones

The DE Series from Minerza is an advanced two-stage hydrocyclone system that integrates primary and secondary classification into a single compact unit — eliminating the need for intermediate pumps, pipes, or sumps. This innovative design streamlines separation processes while improving performance, reducing capital costs, and boosting plant efficiency.

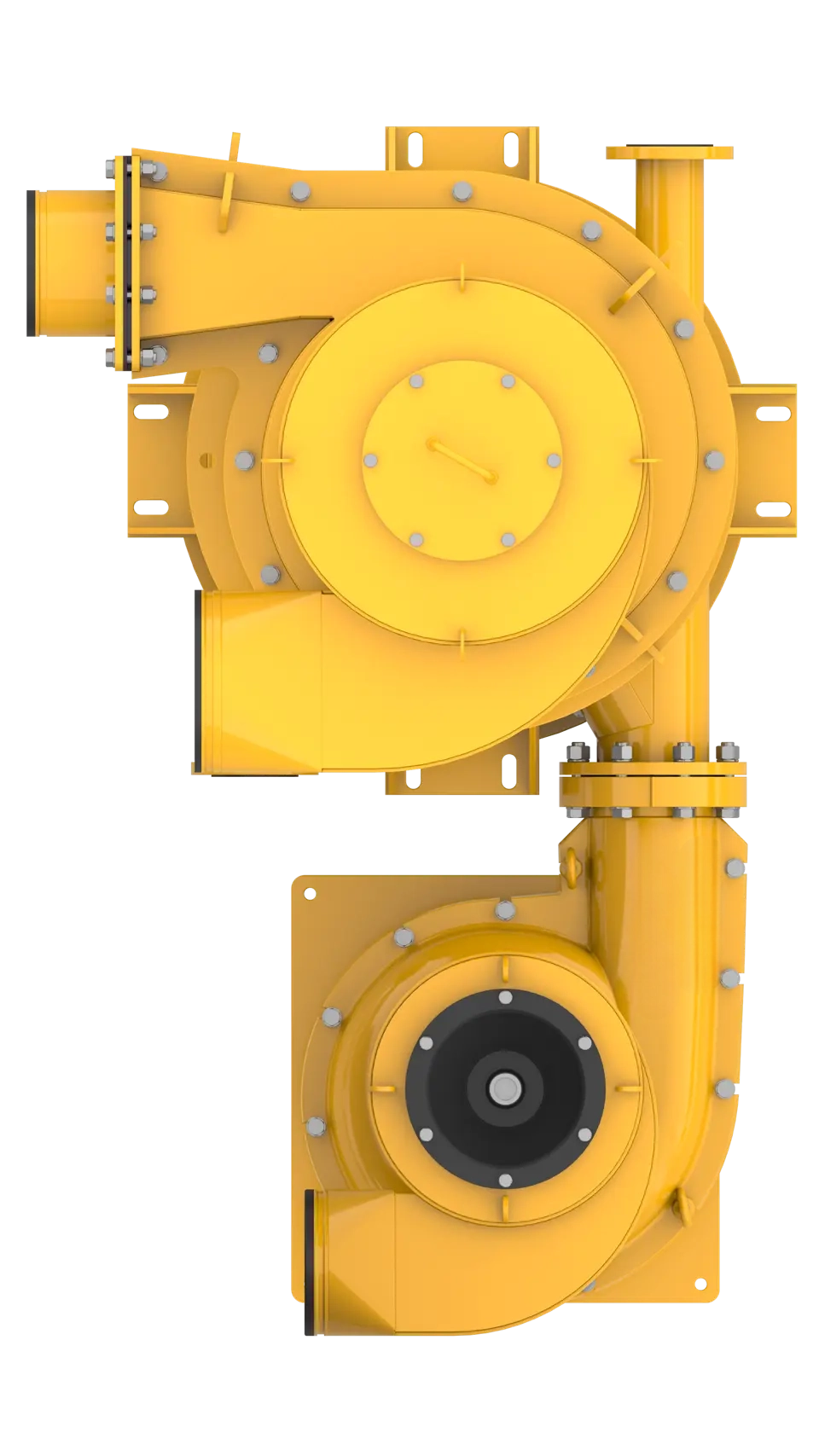

At the core of the DE Series is a double-cone design: the underflow from the primary stage feeds directly into the secondary cyclone via a controlled annular gap, ensuring optimal flow split without additional energy consumption. An integrated Air Core Booster (ACB) on both stages further improves cyclone efficiency by enhancing flow to the overflow and lowering pressure requirements.

Designed especially for desliming and tailings management, DE Series hydrocyclones reduce fine particle bypass to the underflow and minimize coarse particle misplacement to the overflow — key factors in improving mill circuit efficiency and flotation performance.

The system delivers dense underflows for safe and stable tailings dam construction, while the two-in-one configuration significantly reduces maintenance, wear, and total cost of ownership.

Design

Two-stage classification in a single unit with internal slurry transfer and ACB integration

Materials

Metal body, lined with rubber, ceramic, or polyurethane

Size Range

250 mm to 650 mm diameter

Housing

Steel, abrasion-resistant

Liners

Solid polyurethane, monolithic ceramic, or poly liners

Pressure Class

0 – 250 kPa

Temperature Range

0 – 80 °C

Applications

Desliming, tailings dewatering, fines recovery, mill circuit optimization