EQUIPMENT

Crushers

Reliable size reduction for demanding mining and processing operations

Crushers are the backbone of the comminution process, performing the critical function of reducing large lumps of mined material into manageable particle sizes for further processing. At Minerza, we offer robust, high-performance crushing solutions engineered to operate under the harshest industrial conditions — from open-pit mines to mineral processing plants.

Our range of crushers includes various types and configurations to suit different materials, capacities, and end-use requirements. We manufacture and supply:

Jaw crushers for coarse primary crushing of hard rock and abrasive materials

Cone crushers for high-efficiency secondary and tertiary crushing

Impact crushers for processing brittle materials and recycling tasks

All crusher designs feature reinforced structures, abrasion-resistant wear parts, and heavy-duty drive systems to ensure continuous operation and minimal maintenance downtime. We also provide complete drive assemblies, hydraulic adjustment systems, base frames, hoppers, and supporting elements — either from our standard catalogue or based on customer drawings and plant layout.

Our crushers are widely used in:

Iron ore and non-ferrous mining

Limestone and cement production

Metallurgical processing

Aggregate plants and recycling facilities

We support both new equipment supply and full-scale retrofitting or replacement of existing crusher installations. In addition, we offer custom manufacturing of housings, shafts, rotor assemblies, and liners according to customer-provided 2D/3D technical documentation.

All components undergo rigorous quality control and are produced from certified materials selected for durability and compatibility with extreme mechanical and thermal loads.

If you require reliable crushing equipment tailored to your production needs, Minerza offers complete solutions — from single units to integrated crushing stations.

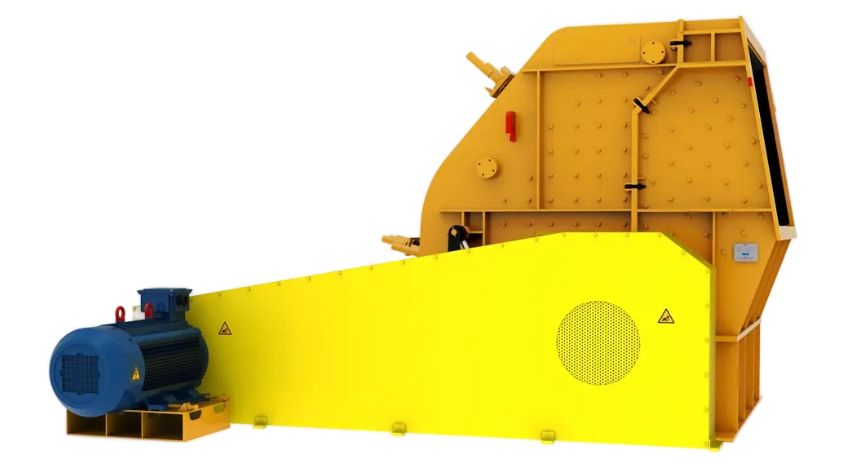

JAW CRUSHER

EM Series Jaw Crusher

The EM Series delivers reliable primary crushing for hard and abrasive rock. Built for durability and uptime, these jaw crushers offer high feed capacity, reinforced components, and simplified maintenance—making them ideal for mining, aggregate, and heavy industrial applications.

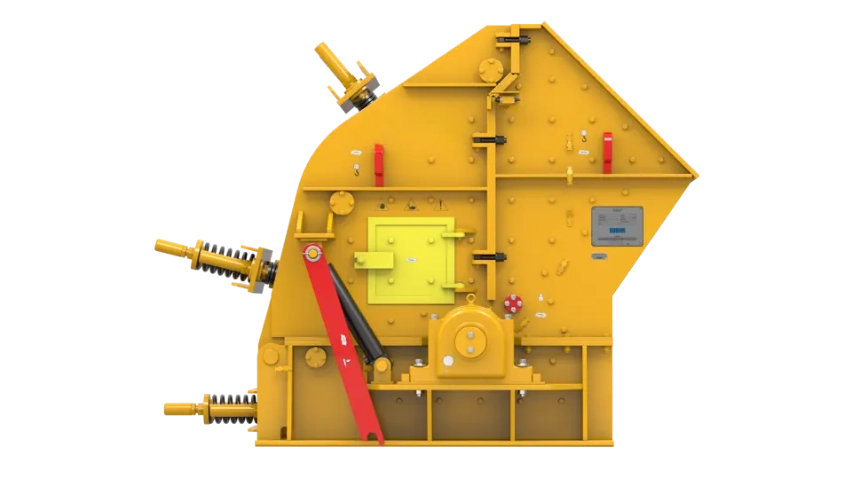

IMPACT CRUSHER

AR Series Impact Crusher

AR Series horizontal shaft impact crushers deliver high reduction ratios and accept large feed sizes, making them ideal for primary crushing in challenging conditions. Designed for precise particle shape and efficient processing, they outperform traditional compression crushers when shape is critical.

IMPACT CRUSHER

AS Series Impact Crusher

AS Series horizontal impact crushers are engineered for efficient secondary crushing without sacrificing product quality or size. With a large open feed area, they handle slabby materials like concrete and asphalt with ease. Their steep feed angle, tight rotor-to-curtain clearance, and optional third curtain make them ideal for aggregate and recycling operations.

IMPACT CRUSHER

VI Series Impact Crusher

VI Series vertical impact crushers are designed for precision shaping and fine aggregate production in tertiary and quaternary stages. Ideal for sand and specialty product applications, they feature a modular housing for easy post-sale modification, offering flexibility to adapt to changing process needs.

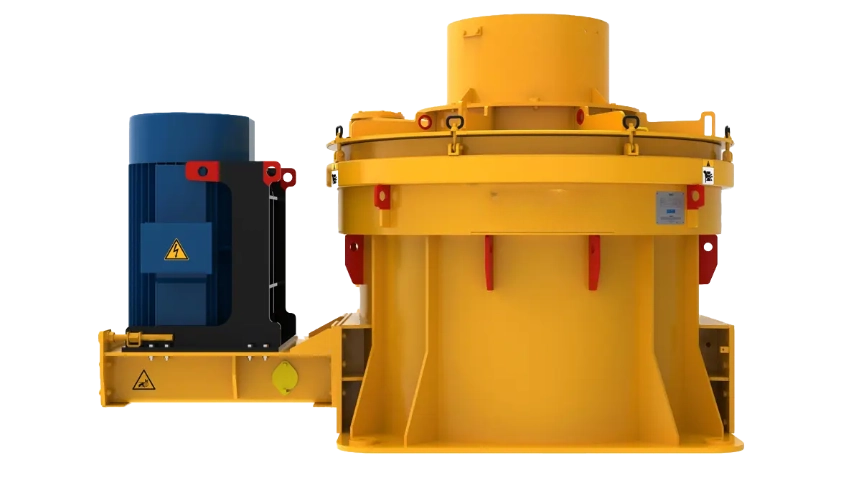

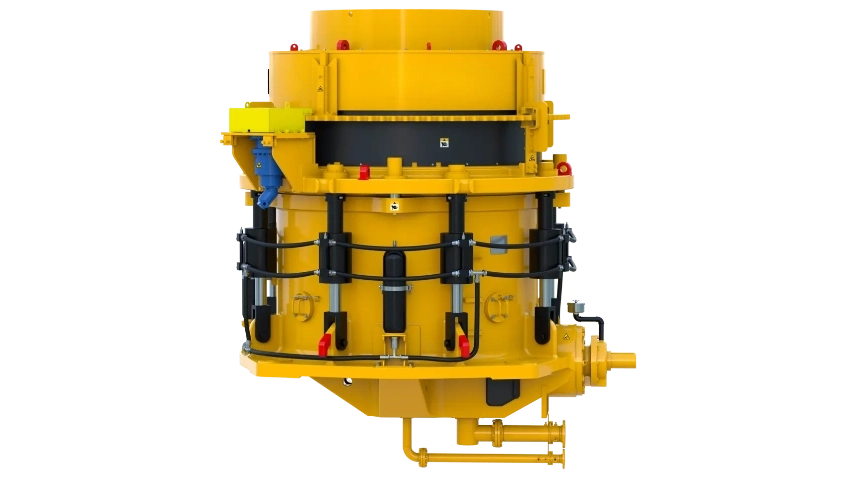

CONE CRUSHER

RC Series Cone Crusher

RC Series cone crushers represent the latest evolution of live-shaft technology. Designed for heavy-duty secondary and tertiary applications, these machines are robust, reliable, and easy to operate. They also perform exceptionally well in pebble crushing scenarios. Building on the proven design of traditional live-shaft crushers, the RC Series integrates modern hydraulic and control systems to efficiently process primary-crushed ores, quarry aggregates, and hard pebbles.

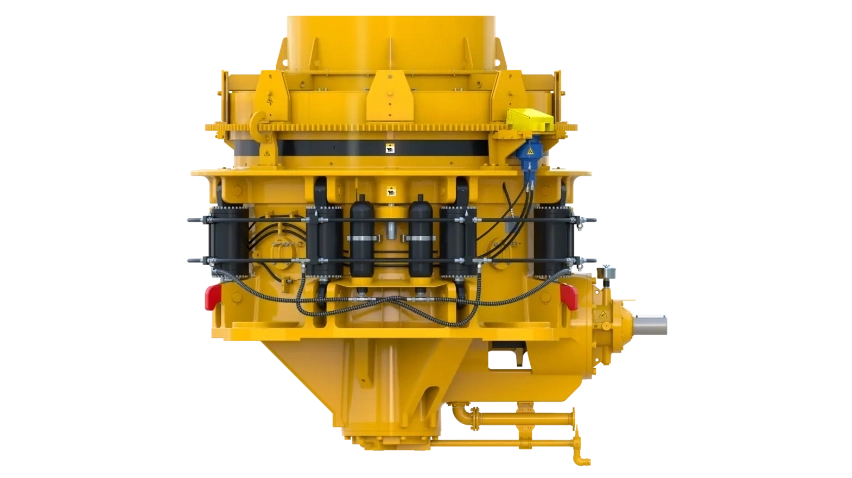

CONE CRUSHER

AX Series Cone Crusher

AX Series fixed-shaft cone crushers are engineered to optimize the balance between power, force, and capacity. These compact yet powerful machines are ideal for secondary and tertiary applications where precise shape and high throughput are essential. Perfectly suited for producing cubical products, they are widely used in crushing circuits for ore preparation, leaching, milling, or size classification in demanding mining and aggregate environments.

Mills

Energy-efficient grinding solutions for mineral processing

Mills play a critical role in reducing crushed ore into fine particles suitable for further separation and recovery. At Minerza, we offer a comprehensive range of grinding technologies built for durability, process stability, and continuous operation under heavy loads.

Ball mills. Versatile wet or dry grinding of ores, cement clinker, and bulk materials

SAG mills (Semi-Autogenous). High-throughput primary grinding using a combination of ore and grinding media

Vertical tower mills. Compact, energy-efficient grinding for fine and ultra-fine applications

High Pressure Grinding Rolls (HPGR). Efficient size reduction through inter-particle compression, enhancing downstream recovery and lowering energy consumption.

All mills are equipped with reinforced shells, abrasion-resistant liners, efficient drive systems, and customizable discharge solutions. We support both trunnion and peripheral discharge types and can integrate mills into closed grinding circuits with classifiers and hydrocyclones.

Minerza supplies complete mills as well as individual components such as shells, trunnions, heads, gears, liners, and bearing assemblies — including custom manufacturing based on client drawings and specifications.

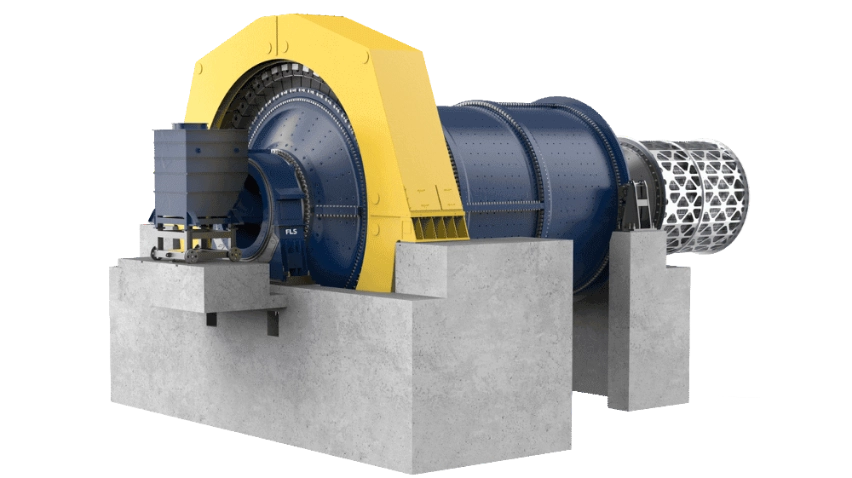

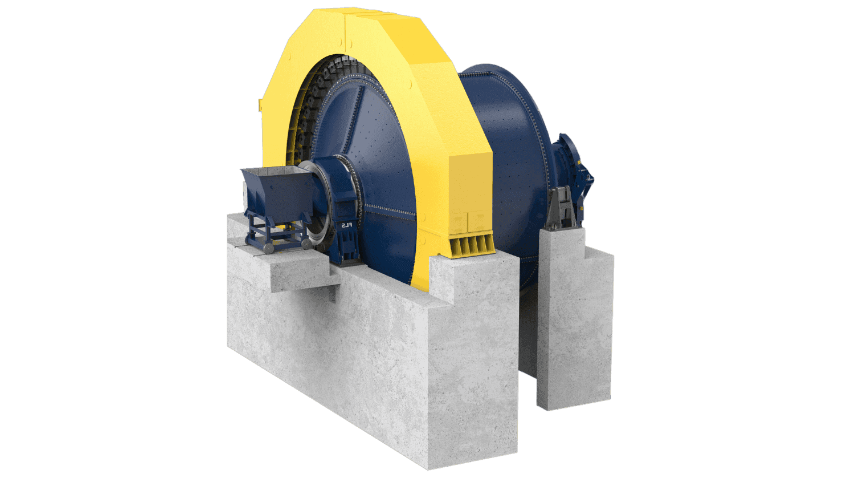

BALL MILL

MBX Series Ball Mill

The MBX Series ball mills are built for heavy-duty grinding of hard and abrasive materials. With optimized liners and energy-efficient drive systems, they offer extended service life and precision in ore processing, cement production, and other demanding operations.

BALL MILL

SGX Series SAG Mill

The SGX Series SAG mill delivers high-throughput grinding for large-scale mining operations. Using both ore and steel balls as grinding media, it’s ideal for primary processing of hard ores like gold, copper, and iron. With low energy consumption and robust design, it ensures reliable performance and reduced operating costs.

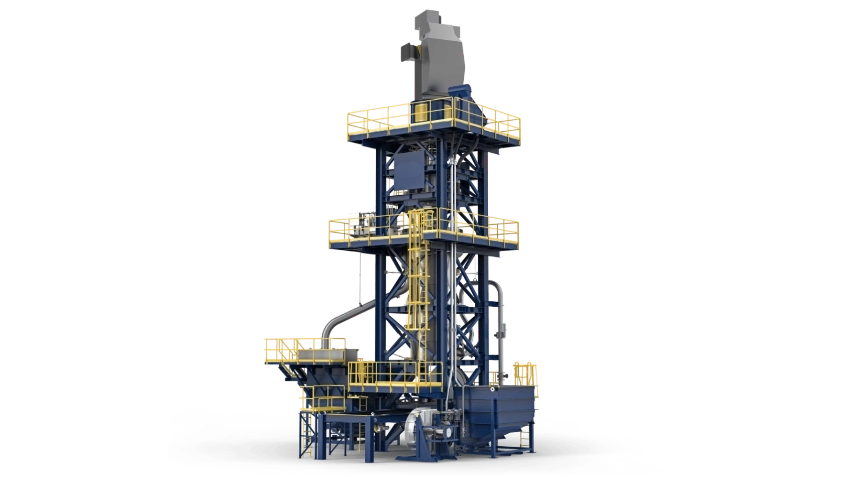

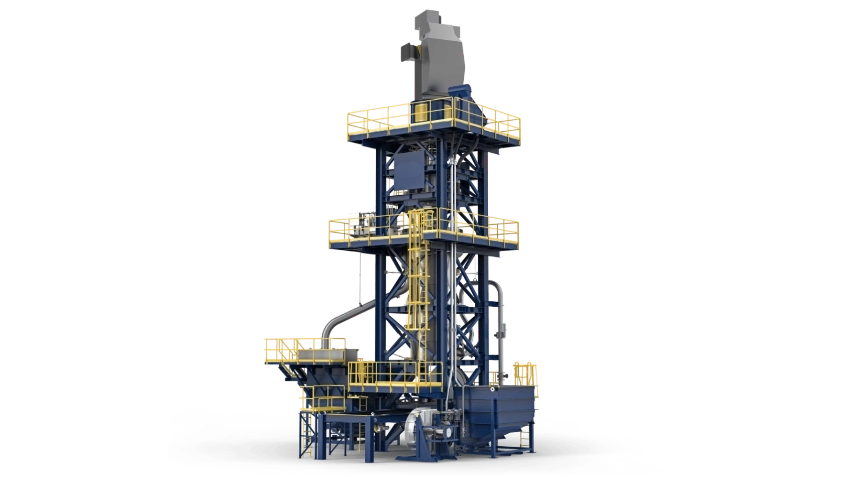

TOWER MILL

TXP Series Tower Mill

The TXP Series tower mill is a vertical, energy-efficient solution for fine and ultra-fine grinding below 30 microns. Using ceramic media and a modular impeller system, it delivers high-intensity attrition grinding with low energy consumption. Ideal for mineral processing where precision, flexibility, and efficiency are critical.

TOWER MILL

TXP Series Tower Mill

The TXP Series tower mill is a vertical, energy-efficient solution for fine and ultra-fine grinding below 30 microns. Using ceramic media and a modular impeller system, it delivers high-intensity attrition grinding with low energy consumption. Ideal for mineral processing where precision, flexibility, and efficiency are critical.