EQUIPMENT

Kilns

Minerza supplies a comprehensive range of industrial kilns engineered for high-efficiency thermal processing across cement, metallurgy, and chemical sectors. Our portfolio includes gear-driven rotary kilns, indirectly heated rotary kilns, and high-temperature shaft kilns, each designed to meet specific process requirements and energy performance standards.

Rotary kilns offer continuous, high-throughput operation with excellent temperature control, suitable for calcination, sintering, and pyrolysis. Gear-driven models ensure smooth rotation and long-term mechanical stability, even in harsh conditions. For processes requiring indirect heating—such as materials sensitive to combustion gases—our indirectly heated kilns deliver precise thermal transfer without direct flame contact.

Shaft kilns provide a compact and fuel-efficient alternative for vertical calcination, commonly used in lime and dolomite production. Their counter-current operation maximizes heat recovery and reduces emissions, making them ideal for applications where space, energy efficiency, and environmental compliance are critical.

Whether your operation demands high-capacity rotary systems or compact shaft configurations, Minerza kilns are built to deliver consistent product quality, reduced fuel consumption, and seamless integration into complex process lines.

KILN

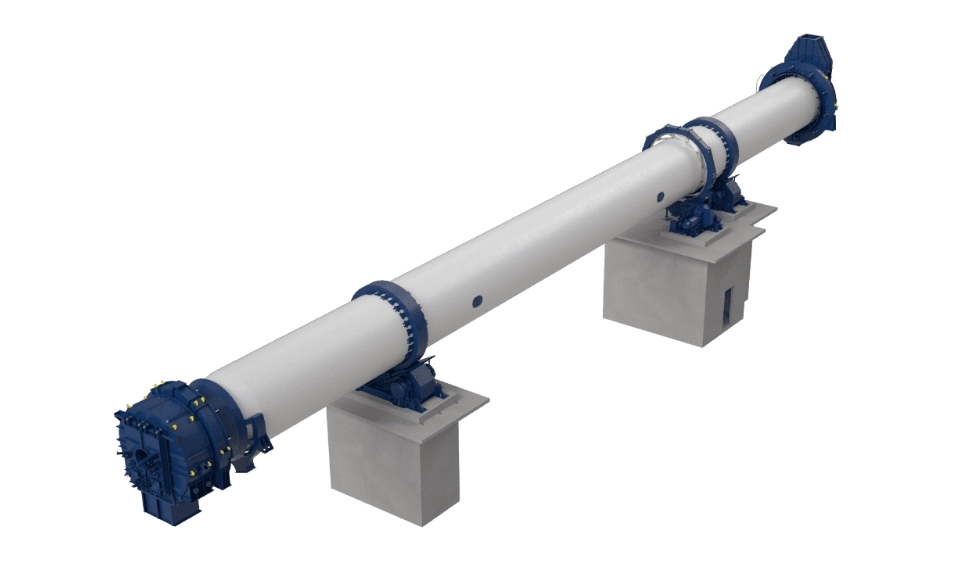

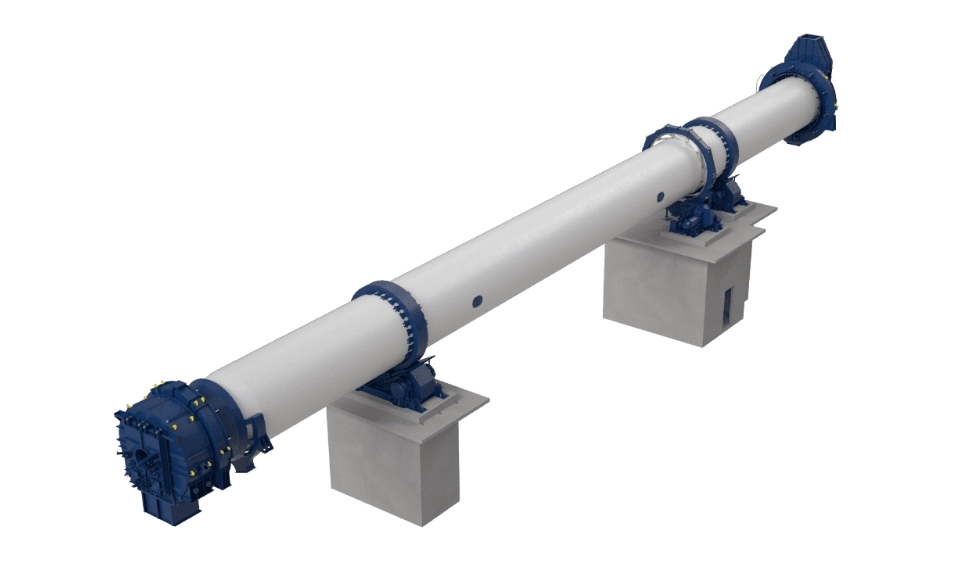

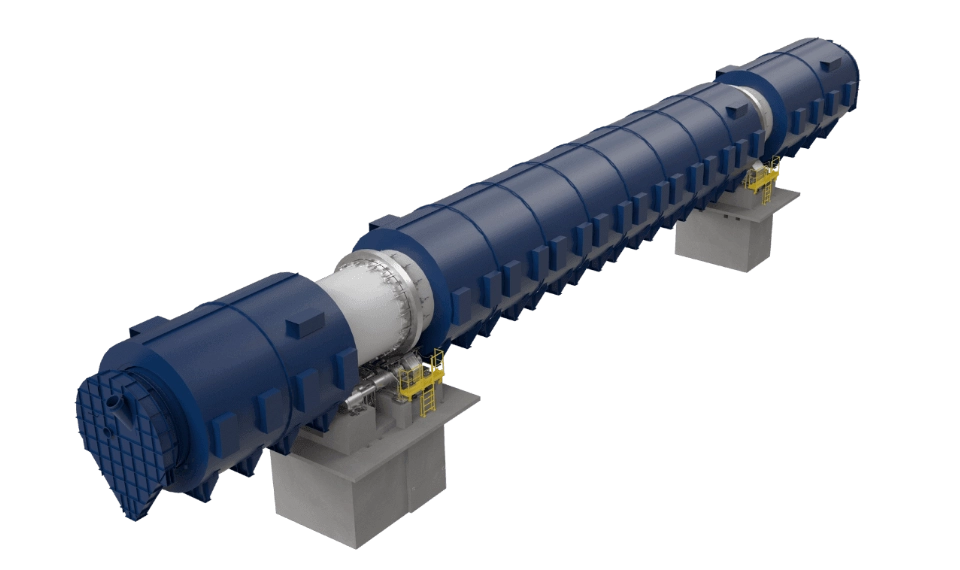

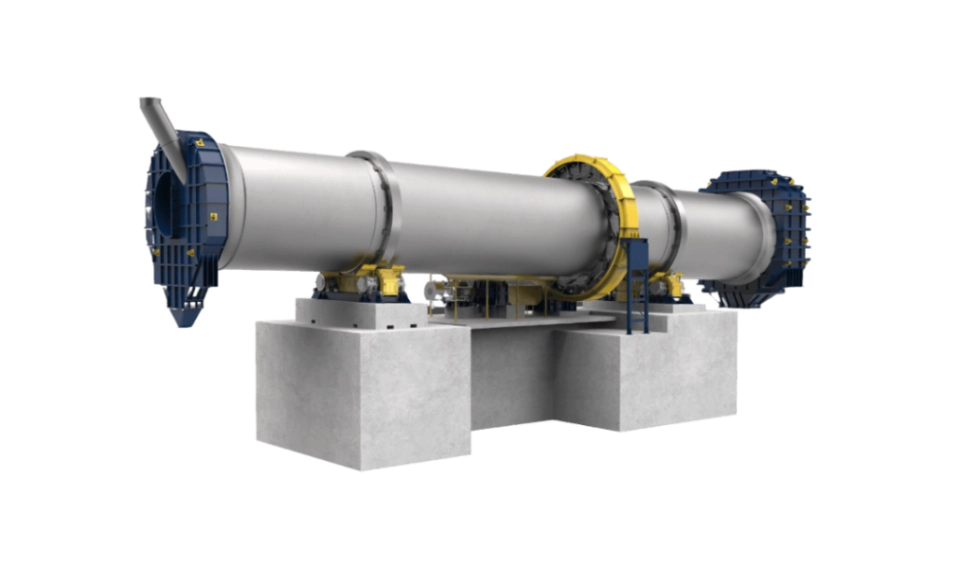

KRN Series – Gear-Drive Rotary Kiln

Versatile gear-driven rotary kilns engineered for high-capacity thermal processing of cement, lime, and industrial minerals with advanced efficiency and process control.

KILN

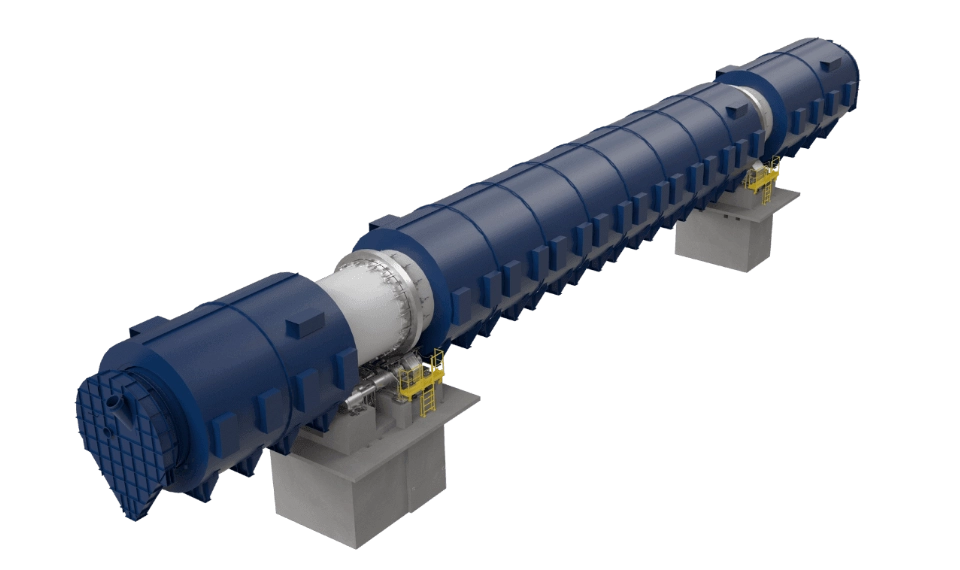

KRI Series – Indirectly-Heated Rotary Kiln

Indirectly-heated rotary kilns engineered for precise thermal processing of sensitive or hazardous materials in inert or sealed environments.

KILN

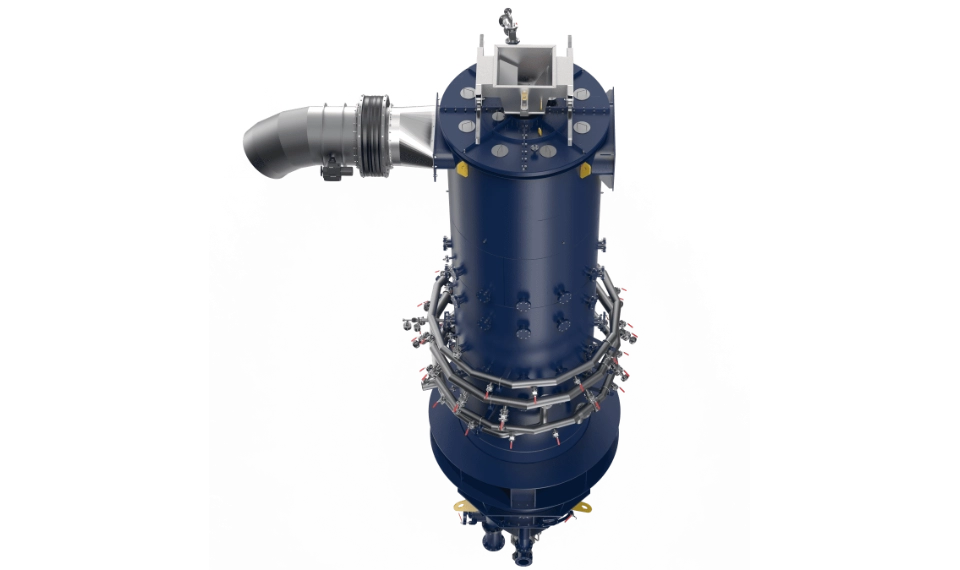

KSH Series – High-Temperature Shaft Kiln

Vertical shaft kilns designed for high-temperature calcination with superior thermal efficiency, ideal for continuous lime and refractory material production.

KILN

KRN Series – Gear-Drive Rotary Kiln

Versatile gear-driven rotary kilns engineered for high-capacity thermal processing of cement, lime, and industrial minerals with advanced efficiency and process control.

KILN

KRI Series – Indirectly-Heated Rotary Kiln

Indirectly-heated rotary kilns engineered for precise thermal processing of sensitive or hazardous materials in inert or sealed environments.

KILN

KSH Series – High-Temperature Shaft Kiln

Vertical shaft kilns designed for high-temperature calcination with superior thermal efficiency, ideal for continuous lime and refractory material production.

Heaters and Dryers

Dryers and heaters play a critical role in thermal processing systems, delivering controlled heat treatment for a wide range of industrial materials. Whether used for moisture removal, temperature elevation, or chemical transformation, these systems are essential for efficient material preparation prior to calcination, grinding, combustion, or storage.

Designed for integration into cement, mining, and energy production lines, both dryers and heaters can be configured for direct or indirect heating, offer high thermal efficiency, and support various material characteristics—from fine powders to cohesive clays and mineral aggregates. Their robust construction and customizable gas flow profiles ensure stable performance in demanding environments.

Flash Dryers

Engineered for high-speed drying of fine-grained materials with high initial moisture content, flash dryers use a turbulent hot gas stream to instantly remove water in a vertical drying column. Their short residence time minimizes energy loss and thermal degradation, making them ideal for clay, phosphate, or concentrates. Options include bag filters or cyclones for dust recovery and emissions control.

Rotary Dryers

Built for continuous operation, rotary dryers are best suited for larger, heavier, or more cohesive materials. A rotating drum combined with controlled gas flow allows for consistent heat exposure and efficient moisture removal over longer residence times. Applications range from ores and minerals to industrial byproducts, especially where robust processing is needed.

Flash Heaters

Flash heaters are designed for fast thermal pre-treatment of process materials without full drying. They provide a quick temperature boost using a direct-contact hot gas stream, ideal for fly ash, alternative fuels, or sticky materials. Often installed upstream of kilns, mills, or calciners, they help improve energy efficiency and reduce downstream thermal load.

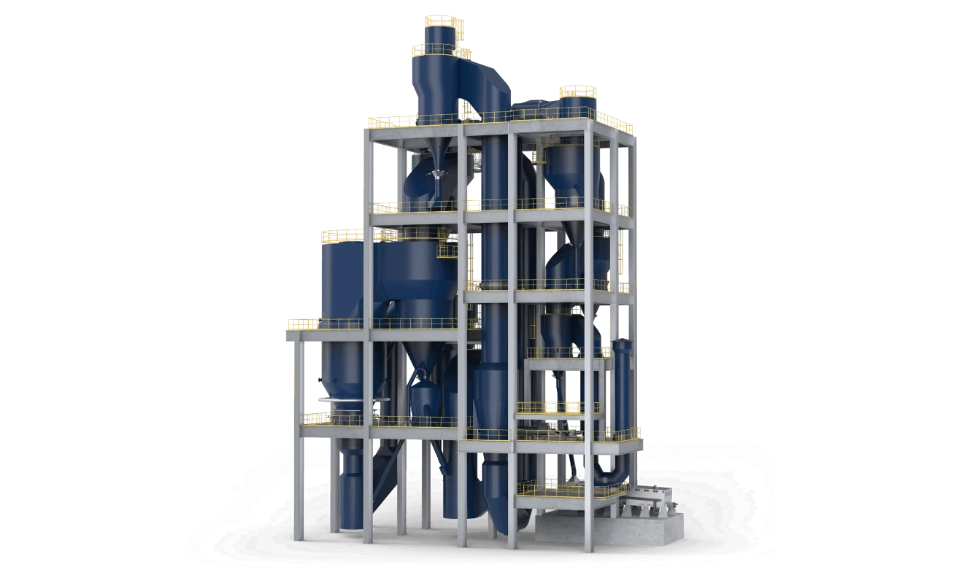

Gas Suspension Calciners

Operating at very high temperatures, gas suspension calciners suspend fine materials in a rising column of hot gases, enabling uniform heating and calcination in a short time. Widely used in preheating towers of cement plants, they reduce energy consumption while delivering consistent product quality.

Multiple Hearth Furnaces

These vertical furnaces provide sequential heating across multiple stacked hearths, allowing for staged drying, roasting, or calcination. Their design supports high throughput, precise temperature zoning, and versatility in handling various materials, including heat-sensitive powders or specialty minerals.

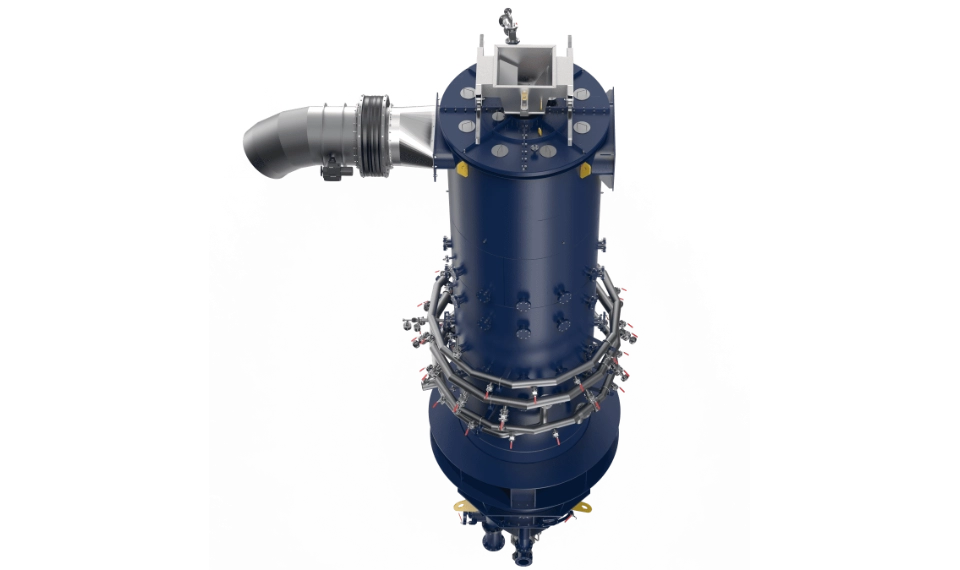

HEATER

HXS Series – Flash Heater for Controlled Preheating

HXS Series flash heaters offer controlled, high-speed preheating for process optimization across cement and energy industries.

DRYER

DLH Series – Flash Dryer for Fine Materials

DLH Series flash dryers deliver rapid and uniform drying for fine materials with high moisture content, ideal for cement and mining applications.

HEATER

GSC Series – Gas Suspension Calciners for Fine-Particle Processing

GSC Series gas suspension calciners deliver fast, uniform calcination of fine materials using hot gas suspension, ideal for cement and alumina industries.

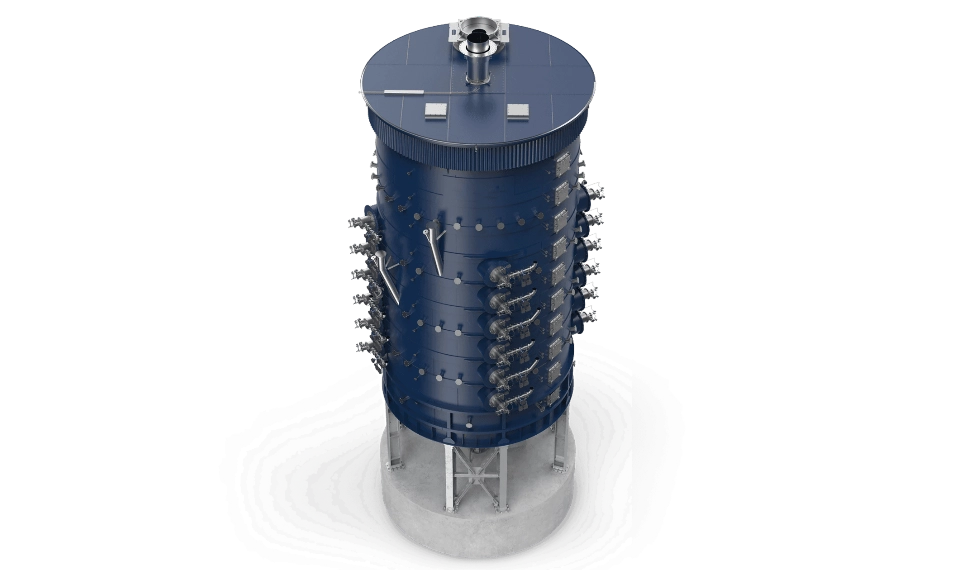

HEATER

MHF Series – Multiple Hearth Furnaces for Thermal Conversion

MHF Series multiple hearth furnaces provide versatile, controlled thermal processing for complex materials in energy, metallurgy, and chemical applications.

DRYER

RTD Series – Heavy-Duty Rotary Dryers for Industrial Applications

RTD Series rotary dryers deliver efficient moisture removal and rugged performance for bulk materials in mining, cement, and industrial processing.