KRI Series – Indirectly-Heated Rotary Kiln

KRI Series – Indirectly-Heated Rotary Kiln

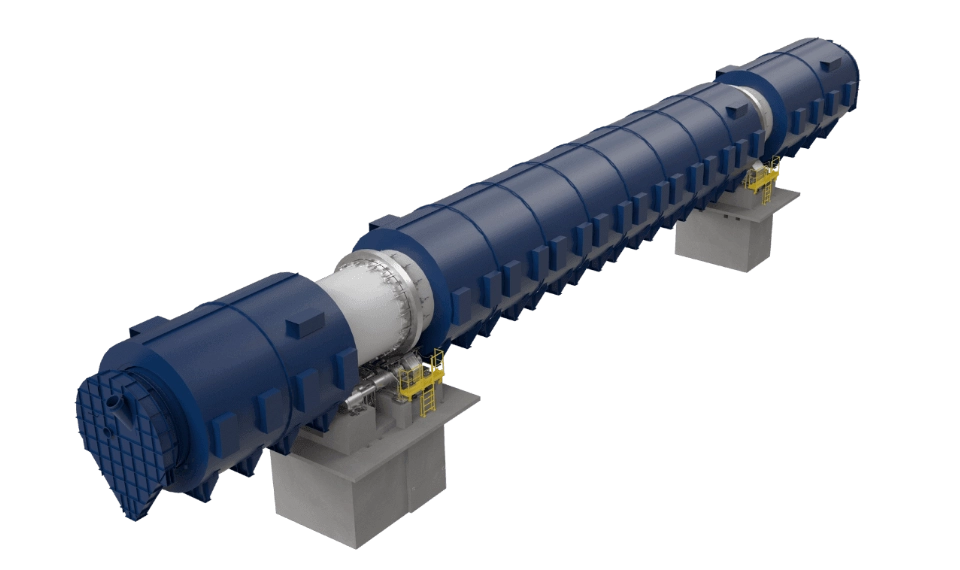

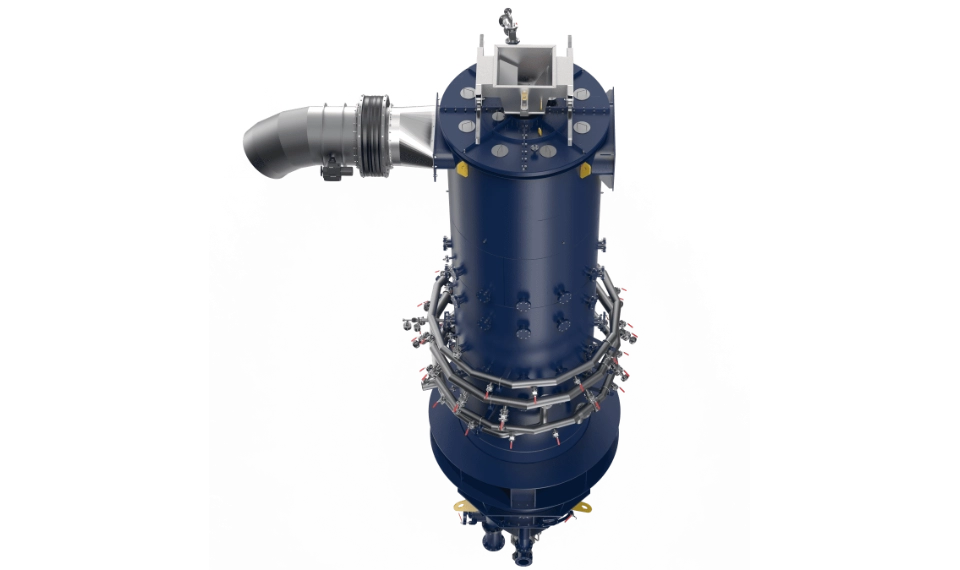

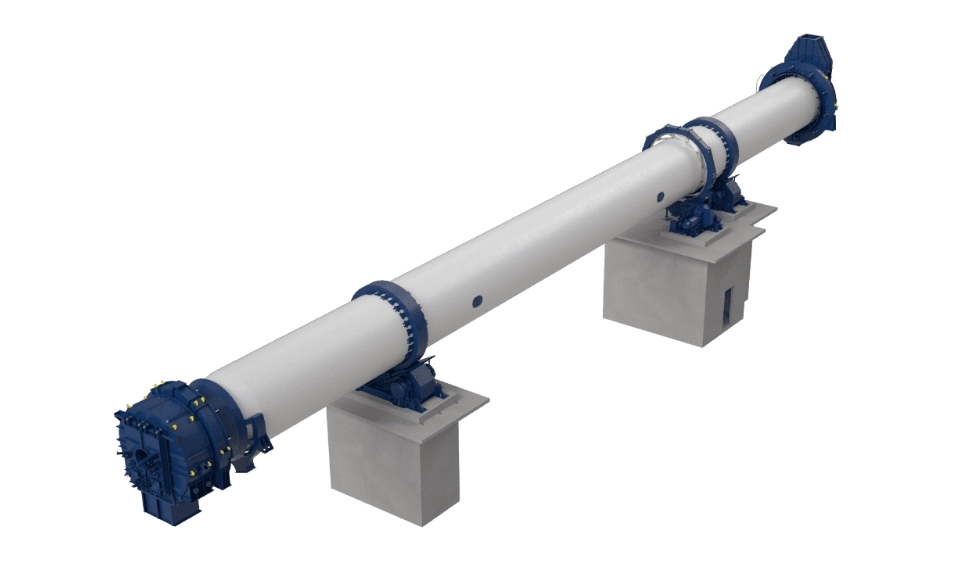

The KRI Series rotary kiln is a highly specialized solution designed for thermal processing applications requiring indirect heat transfer. Unlike direct-fired systems, this kiln uses external heating sources such as gas burners, electric coils, or thermal oil to heat the kiln shell, which in turn radiates heat to the processed material. This eliminates direct contact between the flame and the product, making it ideal for sensitive materials that must be processed in a controlled, inert, or contamination-free environment.

Thanks to its sealed construction, the KRI kiln is well-suited for toxic, reactive, or volatile feedstocks, offering both operational safety and environmental compliance. The rotating drum ensures uniform heat distribution and consistent product quality, while advanced control systems provide precise regulation of residence time, temperature zones, and rotation speed.

These kilns are widely used in the chemical, metallurgical, waste processing, and battery materials industries, particularly for applications such as carbonization, reduction, drying, calcination, and decomposition processes.

Key Specifications:

• Kiln diameter: 0.5 m – 3.5 m

• Length: 2 m – 30 m

• Maximum operating temperature: up to 1100 °C

• Heating method: electric, gas, thermal oil, or steam jackets

• Atmosphere: air, inert gas, vacuum

• Applications: catalyst processing, lithium compounds, metal oxides, hazardous waste treatment

• Sealing systems: labyrinth, mechanical, or pneumatic seal options

• Optional features: gas-tight chambers, integrated condensers, automated feeding systems