EQUIPMENT

Crushers

Crushers play a crucial role in the cement production process, performing the essential task of reducing raw materials and semi-processed clinker into consistent particle sizes for further handling and grinding. At Minerza, we deliver durable, high-efficiency crushing solutions tailored for the specific challenges of cement plants — from limestone quarries to pre-grinding stages.

Our range includes crushers designed for various stages of cement production. We manufacture and supply:

• Jaw crushers for coarse primary crushing of limestone and other hard feedstocks

• Cone crushers for secondary reduction and material shaping

• Impact crushers for brittle materials and cement clinker crushing

All crushers feature reinforced housings, abrasion-resistant linings, and heavy-duty drives to ensure continuous operation with minimal downtime. Complete drive assemblies, base frames, and support structures are available — either from our standard catalogue or built to customer specifications.

Our crushers are widely used in:

• Limestone quarrying

• Raw material preparation

• Clinker crushing and pre-grinding

• Alternative fuels and by-product recycling

We support both new installations and retrofits of existing crushing stations. We also offer custom manufacturing of housings, shafts, rotors, and liners based on customer-supplied 2D/3D drawings.

All components are manufactured from certified materials and tested to meet the mechanical and thermal demands of cement production.

Whether you’re upgrading part of your plant or building a new crushing line, Minerza provides fully integrated solutions for efficient and reliable cement material reduction.

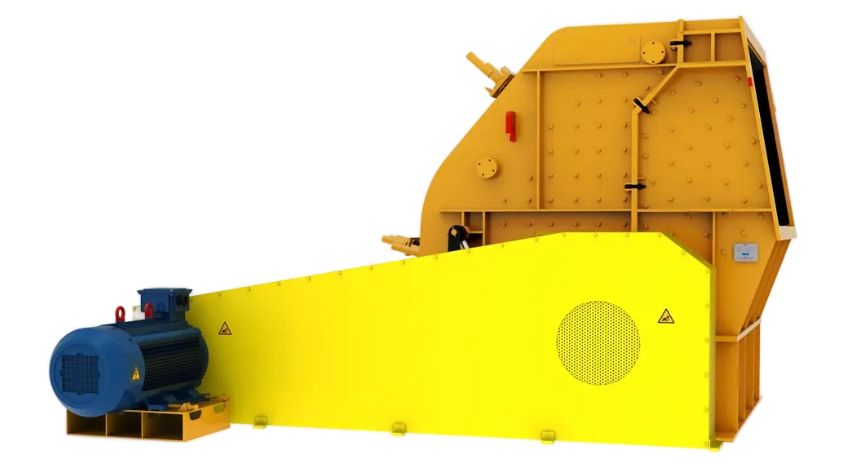

JAW CRUSHER

EM Series Jaw Crusher

The EM Series delivers reliable primary crushing for hard and abrasive rock. Built for durability and uptime, these jaw crushers offer high feed capacity, reinforced components, and simplified maintenance—making them ideal for mining, aggregate, and heavy industrial applications.

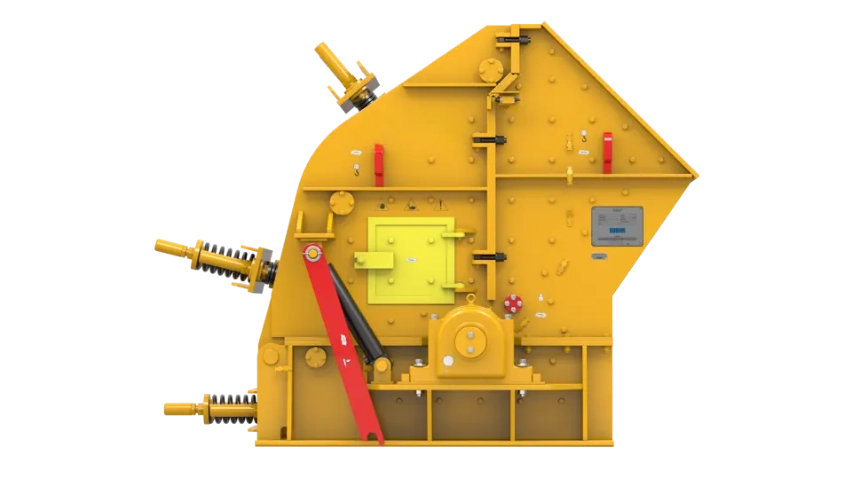

IMPACT CRUSHER

AR Series Impact Crusher

AR Series horizontal shaft impact crushers deliver high reduction ratios and accept large feed sizes, making them ideal for primary crushing in challenging conditions. Designed for precise particle shape and efficient processing, they outperform traditional compression crushers when shape is critical.

IMPACT CRUSHER

AS Series Impact Crusher

AS Series horizontal impact crushers are engineered for efficient secondary crushing without sacrificing product quality or size. With a large open feed area, they handle slabby materials like concrete and asphalt with ease. Their steep feed angle, tight rotor-to-curtain clearance, and optional third curtain make them ideal for aggregate and recycling operations.

IMPACT CRUSHER

VI Series Impact Crusher

VI Series vertical impact crushers are designed for precision shaping and fine aggregate production in tertiary and quaternary stages. Ideal for sand and specialty product applications, they feature a modular housing for easy post-sale modification, offering flexibility to adapt to changing process needs.

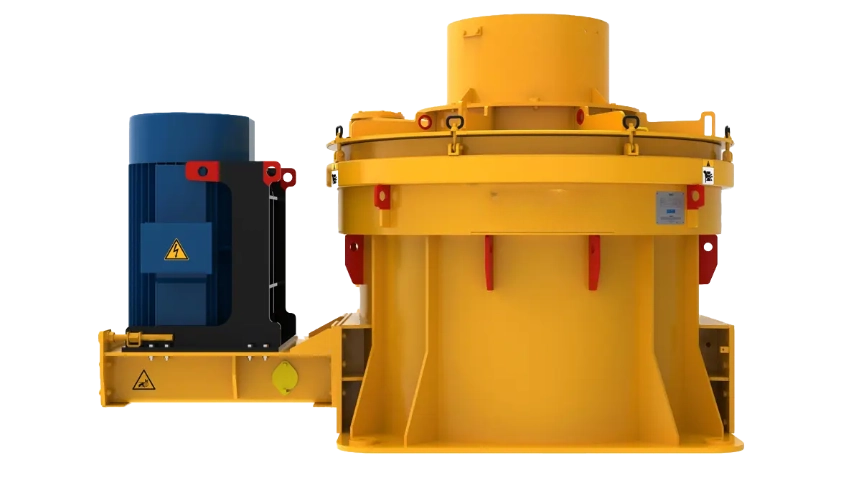

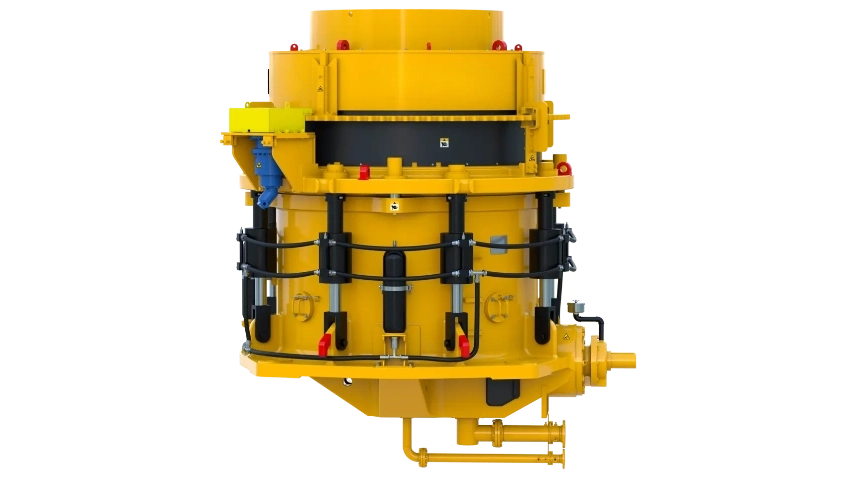

CONE CRUSHER

RC Series Cone Crusher

RC Series cone crushers represent the latest evolution of live-shaft technology. Designed for heavy-duty secondary and tertiary applications, these machines are robust, reliable, and easy to operate. They also perform exceptionally well in pebble crushing scenarios. Building on the proven design of traditional live-shaft crushers, the RC Series integrates modern hydraulic and control systems to efficiently process primary-crushed ores, quarry aggregates, and hard pebbles.

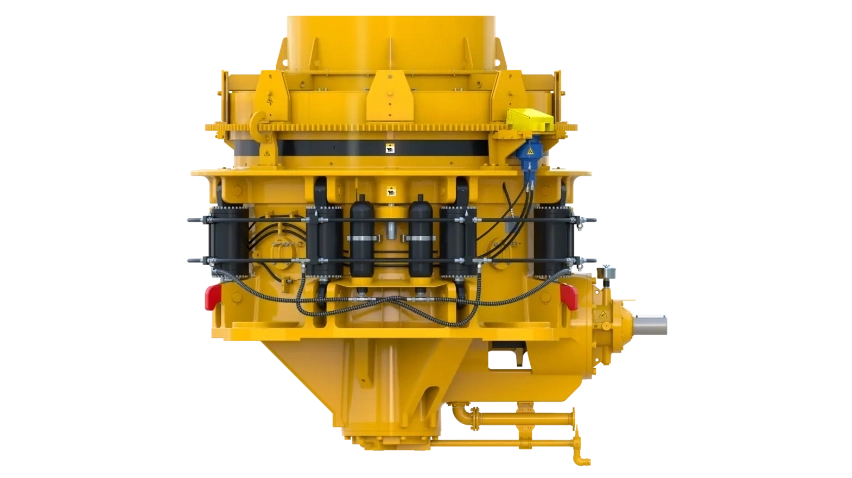

CONE CRUSHER

AX Series Cone Crusher

AX Series fixed-shaft cone crushers are engineered to optimize the balance between power, force, and capacity. These compact yet powerful machines are ideal for secondary and tertiary applications where precise shape and high throughput are essential. Perfectly suited for producing cubical products, they are widely used in crushing circuits for ore preparation, leaching, milling, or size classification in demanding mining and aggregate environments.

Mills

Mills are essential to cement manufacturing, reducing raw materials and clinker into fine powders for pyroprocessing or final product blending. At Minerza, we offer a comprehensive range of grinding technologies engineered for high efficiency, durability, and continuous performance in cement plant environments.

We manufacture and supply:

• Ball mills. Reliable dry or wet grinding of cement raw mix and clinker at all production stages

• Vertical roller mills (VRMs). High-efficiency grinding with reduced energy consumption and compact footprint

• Horizontal mills. Traditional large-scale grinding systems for consistent particle size

• High-pressure grinding rolls (HPGR). Pre-grinding and finish grinding with energy-saving compression-based grinding

All mills are available with reinforced shells, abrasion-resistant liners, heavy-duty gear systems, and discharge configurations tailored to cement applications. We support both open and closed-circuit setups, including integration with separators and dust collection systems.

Minerza supplies complete mill assemblies as well as key components — shells, heads, gears, liners, and trunnions — with custom manufacturing based on your technical drawings and process requirements.

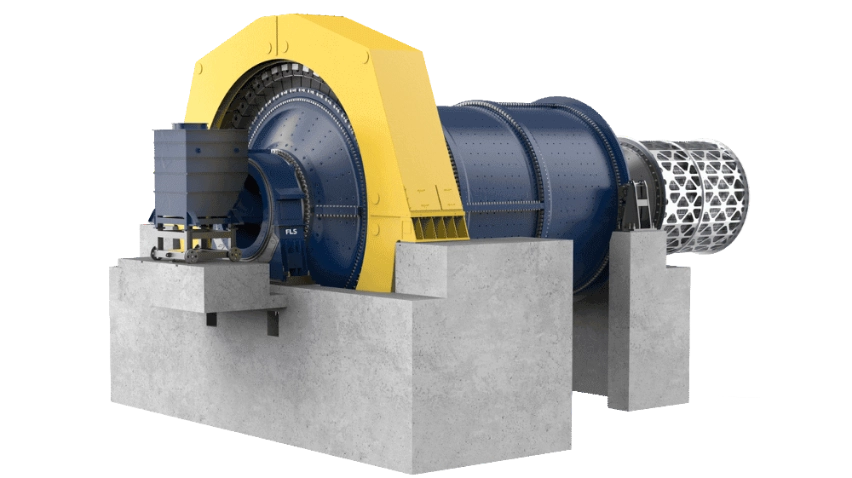

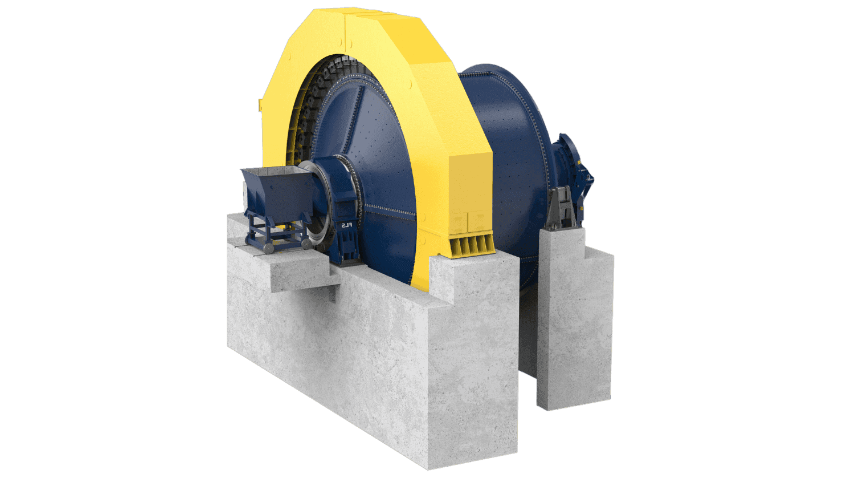

BALL MILL

MBX Series Ball Mill

The MBX Series ball mills are built for heavy-duty grinding of hard and abrasive materials. With optimized liners and energy-efficient drive systems, they offer extended service life and precision in ore processing, cement production, and other demanding operations.

BALL MILL

SGX Series SAG Mill

The SGX Series SAG mill delivers high-throughput grinding for large-scale mining operations. Using both ore and steel balls as grinding media, it’s ideal for primary processing of hard ores like gold, copper, and iron. With low energy consumption and robust design, it ensures reliable performance and reduced operating costs.

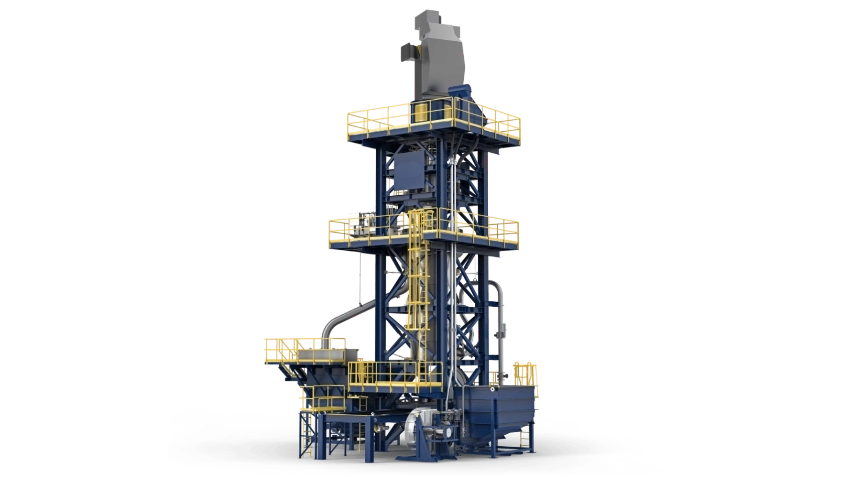

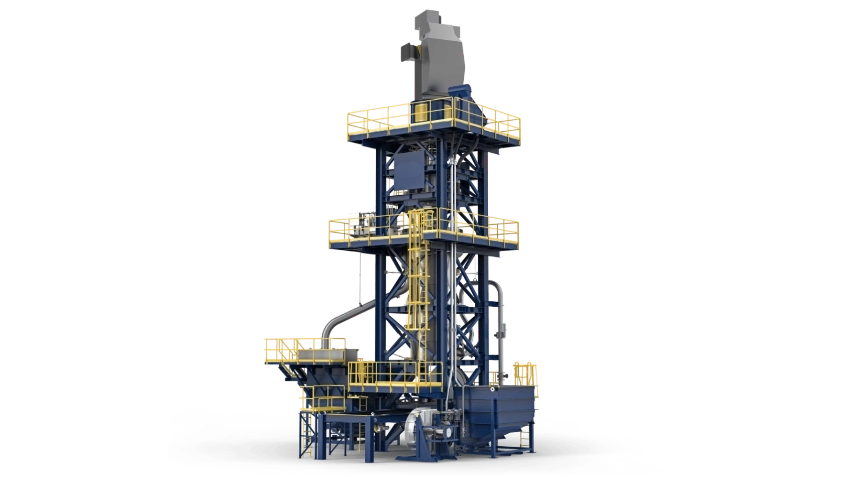

TOWER MILL

TXP Series Tower Mill

The TXP Series tower mill is a vertical, energy-efficient solution for fine and ultra-fine grinding below 30 microns. Using ceramic media and a modular impeller system, it delivers high-intensity attrition grinding with low energy consumption. Ideal for mineral processing where precision, flexibility, and efficiency are critical.

TOWER MILL

TXP Series Tower Mill

The TXP Series tower mill is a vertical, energy-efficient solution for fine and ultra-fine grinding below 30 microns. Using ceramic media and a modular impeller system, it delivers high-intensity attrition grinding with low energy consumption. Ideal for mineral processing where precision, flexibility, and efficiency are critical.

Mobile Crushers

Mobile crushing, screening, and material handling equipment designed for dynamic performance in the most demanding environments.

Minerza supplies a complete range of mobile crushers, screens, and stackers engineered for efficient, on-site material processing in mining, quarrying, infrastructure, and recycling projects. These robust and versatile machines offer exceptional mobility, fast setup times, and reduced operational costs — enabling producers to respond quickly to changing jobsite needs without sacrificing output quality.

Our mobile solutions include jaw crushers for primary reduction of hard rock, impact crushers for high-performance recycling and aggregate shaping, cone crushers for secondary and tertiary applications, and screening units for precise material separation. Mobile stackers further optimize material logistics, streamlining stockpiling and minimizing equipment movement.

Whether for high-capacity crushing or precise screening and stacking, Minerza’s mobile fleet ensures flexible deployment, simplified transport, and maximum uptime — even in the most remote or space-constrained sites.

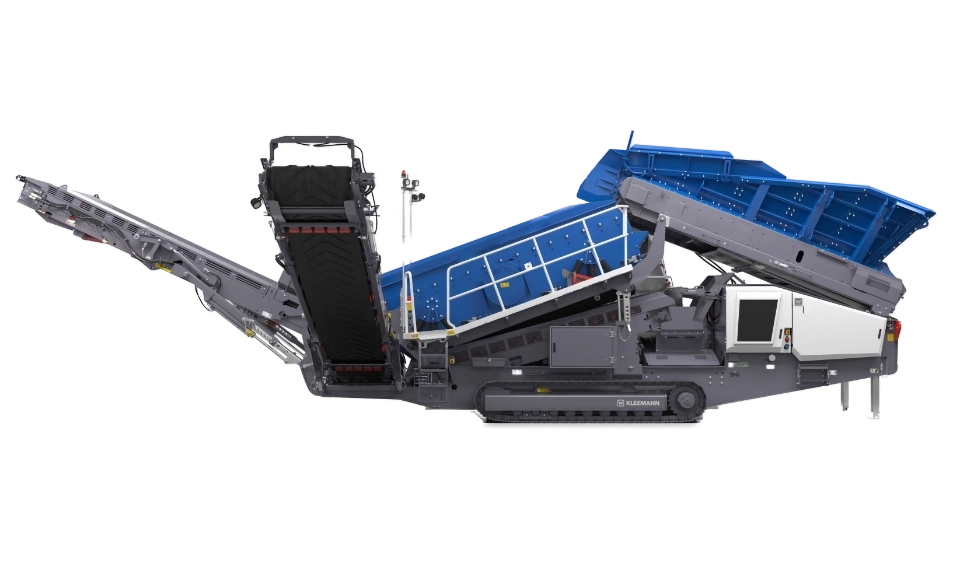

MOBILE CRUSHER

MSQ Series – Mobile Screening Solutions

MSQ Series mobile screening plants offer up to 800 t/h capacity in double or triple‑deck builds, with 7–9.5 m² screen surfaces and efficient H‑DRIVE or diesel–electric systems. Built for fast deployment, precise classification, and seamless integration — ideal for quarries, recycling, and aggregate production.

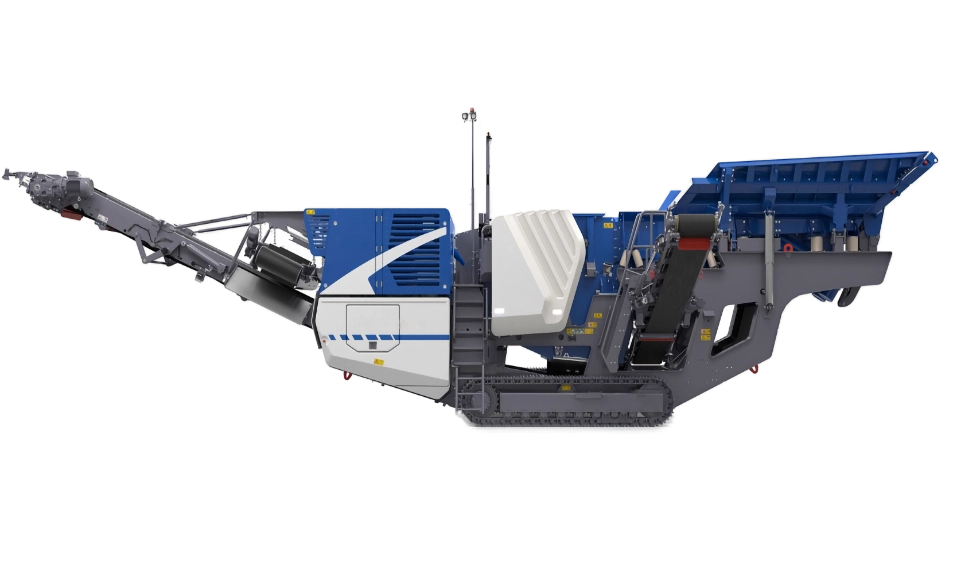

MOBILE CRUSHER

MIC Series – Mobile Impact Crushers for On-Site Reduction

MIC Series mobile impact crushers deliver up to 600 t/h of high-quality reduction in stone and recycling tasks. With large inlets, fuel-efficient drives, and rugged rotors, they ensure powerful on-site crushing with precise grain control — ideal for concrete, asphalt, and demolition recycling.

MOBILE CRUSHER

MCC Series – Mobile Cone Crushers for Precision Final Crushing

MCC Series mobile cone crushers offer high-capacity secondary and tertiary crushing for hard stone and minerals. With advanced cone geometry, adjustable settings, and intelligent overload control, they ensure precise final grain quality — ideal for multi-stage processing on the move.

MOBILE CRUSHER

MCJ Series – Mobile Jaw Crushers for Primary Heavy-Duty Crushing

MCJ Series mobile jaw crushers are built for primary crushing of the hardest materials. Featuring high feed capacities, powerful jaw systems, and advanced control interfaces, they ensure reliable, mobile performance in demanding quarry and recycling environments.

MOBILE CRUSHER

MTS Series – Mobile Stackers for Efficient Material Handling

MTS Series mobile stackers enable flexible stockpiling of bulk materials in quarries and recycling sites. With tracked mobility, high throughput, and compact folding for transport, they reduce handling time and optimize on-site efficiency in aggregate and demolition operations.