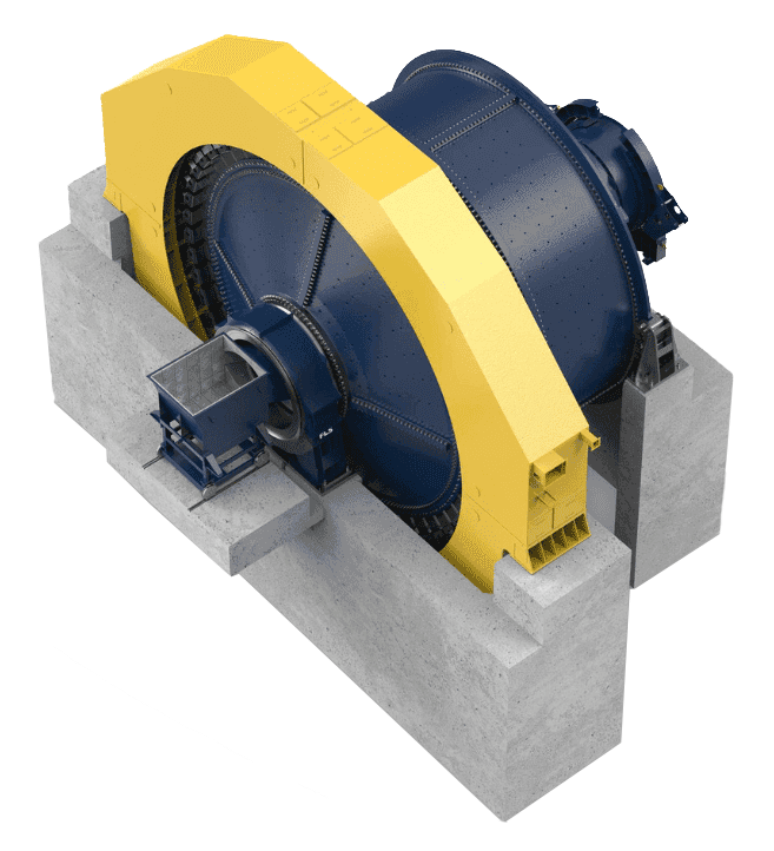

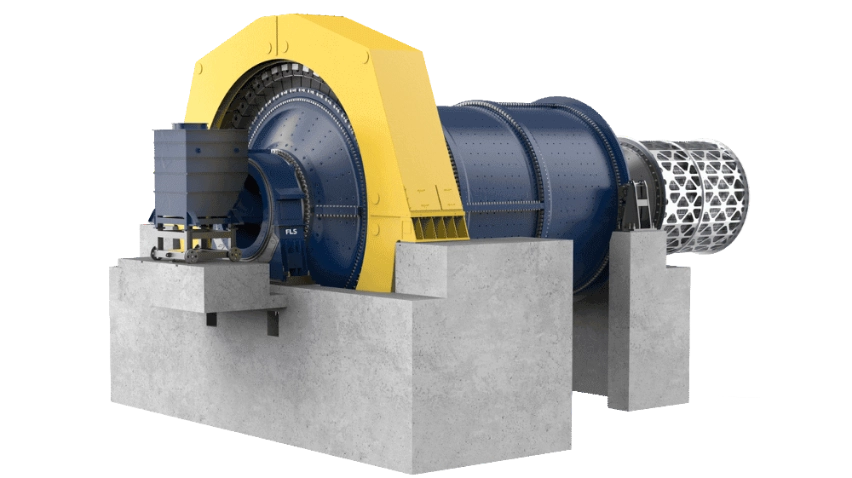

SGX Series SAG Mill

SGX Series SAG Mill

The SGX Series SAG Mill is engineered for high-capacity primary grinding in mineral processing operations. Designed to process large volumes of hard and abrasive ores, such as copper, gold, and iron, this semi-autogenous mill combines the efficiency of ore-on-ore grinding with the added force of grinding balls to achieve optimal size reduction in a single stage.

Ideal for use in large-scale mining and concentrator plants, the SGX Series mill delivers high throughput with reduced energy consumption per ton of material processed. Its rugged shell construction, durable liner systems, and optimized drive configurations ensure long-term performance under the most demanding conditions.

The SGX Series is also compatible with modern automation systems and advanced process control solutions, allowing operators to fine-tune performance, maximize uptime, and minimize operational costs. Whether used in greenfield installations or plant upgrades, it provides the flexibility and efficiency required for reliable mineral recovery.

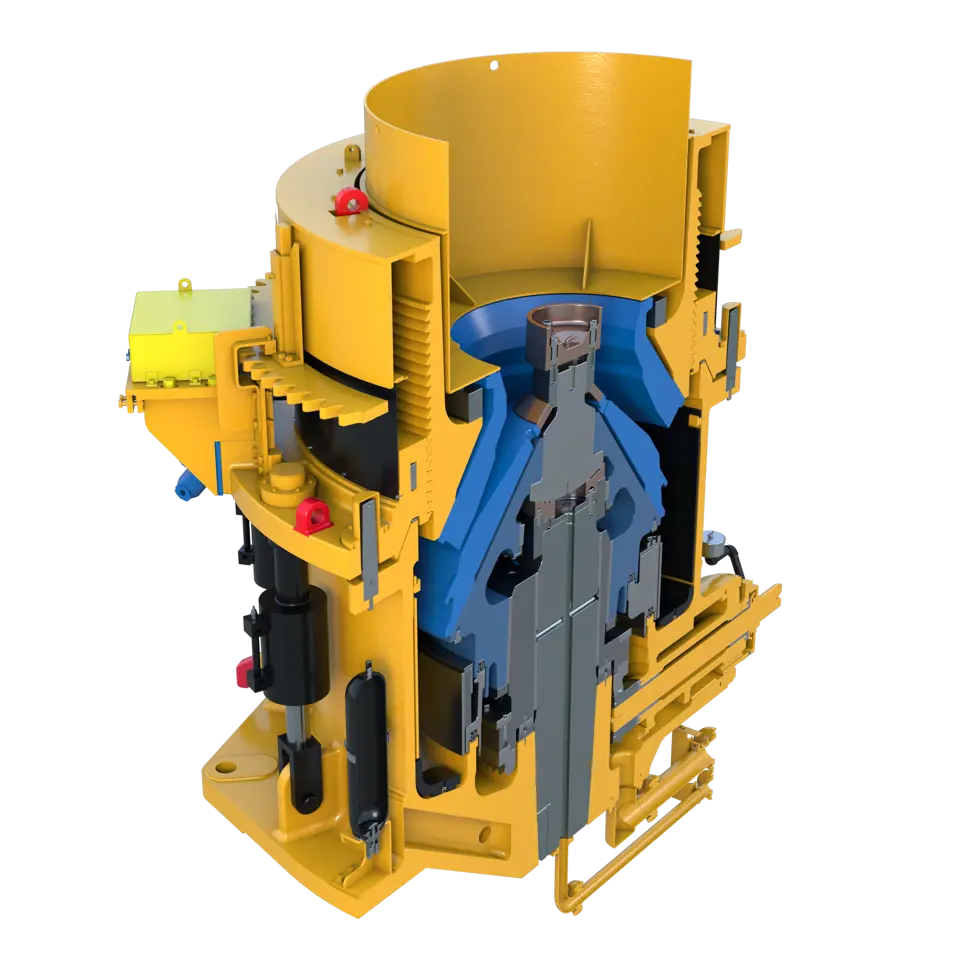

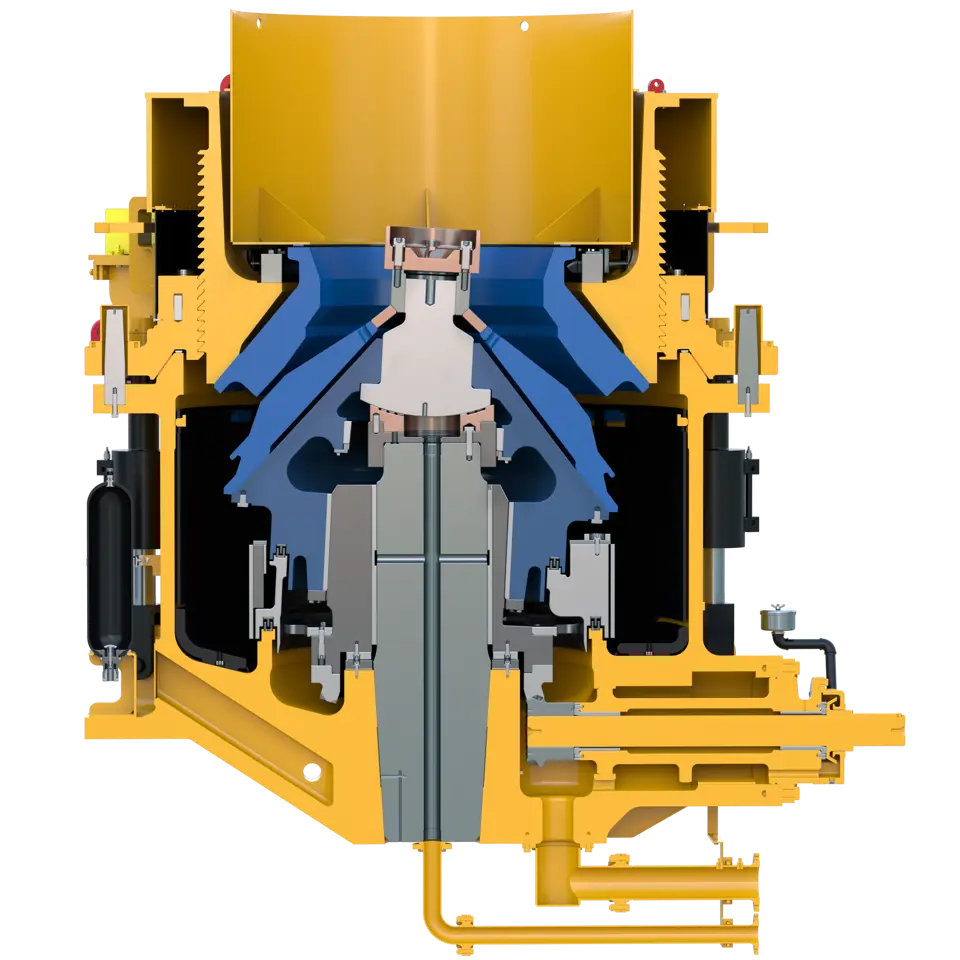

Key Features:

-

Semi-autogenous design using ore and grinding media

-

High-capacity processing for primary and intermediate grinding

-

Suitable for hard, abrasive materials

-

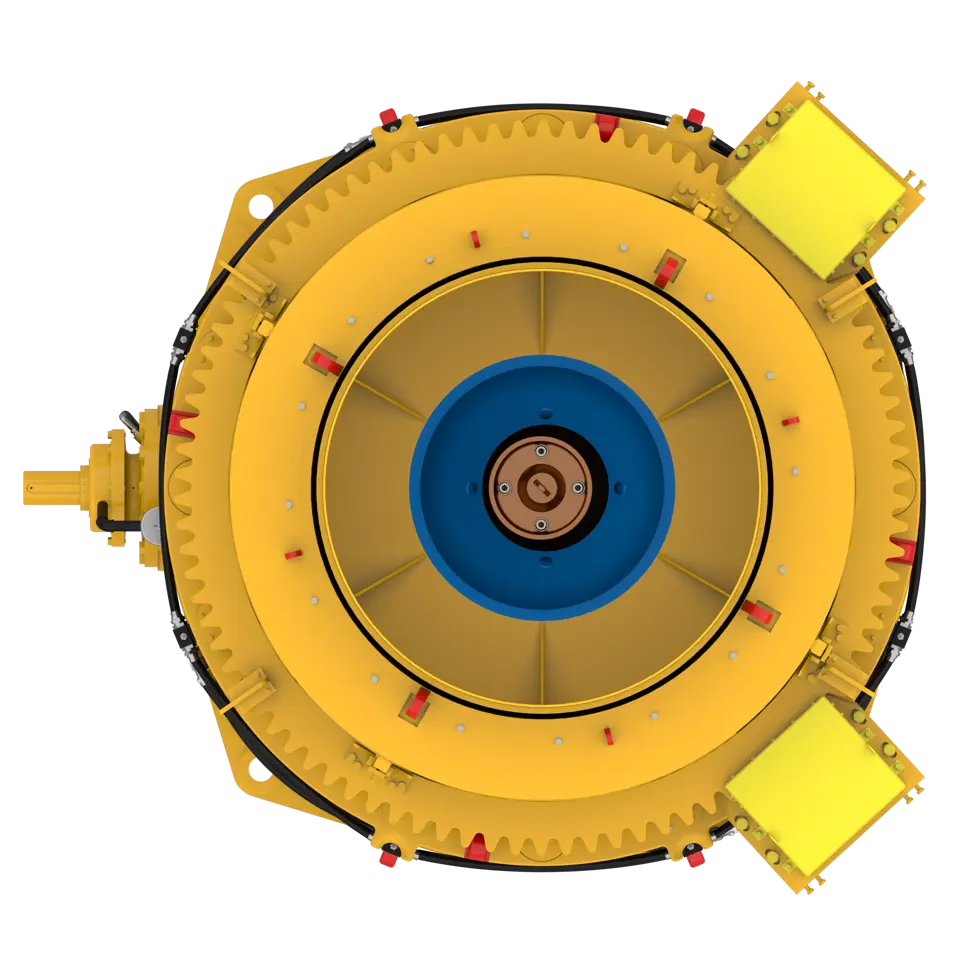

Trunnion or shell-supported configurations

-

Available with single or dual-pinion drives, or gearless mill drive (GMD)

-

Optional digital control and monitoring systems

-

Low operating costs with long service intervals

TECHNICAL SPECIFICATIONS

Materials

Fabricated steel shell with manganese or rubber liners

Grinding Media

Ore and steel balls

Drive Options

Single/dual pinion drive or gearless (wrap-around motor), up to 20,000 kW total

Mill Size

Up to 12.8 meters (42 feet)

Mill Length

Up to 7.0 meters (23 feet)

Product Size Range

P80 from 1 mm to 0.2 mm (dependent on configuration)

Production Capacity

Up to 4,000 mtph

Bearing Options

Hydrodynamic or hydrostatic multi-pad bearings