EQUIPMENT

Conveyors

Minerza delivers a comprehensive range of belt conveyor systems engineered to meet the demands of modern heavy industry, from underground mining operations to high-throughput bulk terminals. Our conveyor solutions are designed for maximum efficiency, safety, and adaptability across a wide spectrum of applications and environments.

The HTR Series is purpose-built for underground and space-restricted areas where conventional conveyor frames are not feasible. Its suspended, chain-supported design eliminates ground interference and ensures flexible deployment, especially in tunneling, maintenance bypass routes, or temporary transport lines.

The VTX Series features a deep V-profile belt geometry supported by angled idlers, allowing for secure and centered transport of bulk materials over long distances. This system is ideal for conveying coal, ore, sand, and other granular materials in mining and energy sectors where spillage control and capacity are critical.

The DSK Series is an enclosed conveyor system designed to minimize dust and material loss during handling. With integrated steel covers, sealing skirts, and maintenance access panels, DSK conveyors offer a clean, safe, and environmentally compliant solution for ports, outdoor installations, and environmentally regulated operations.

Whether operating in tight underground conditions, long-distance mining runs, or dust-sensitive terminals, Minerza’s conveyor systems are engineered for durability, modularity, and performance — ensuring consistent material flow and reduced downtime in the world’s most demanding industries.

CONVEYOR

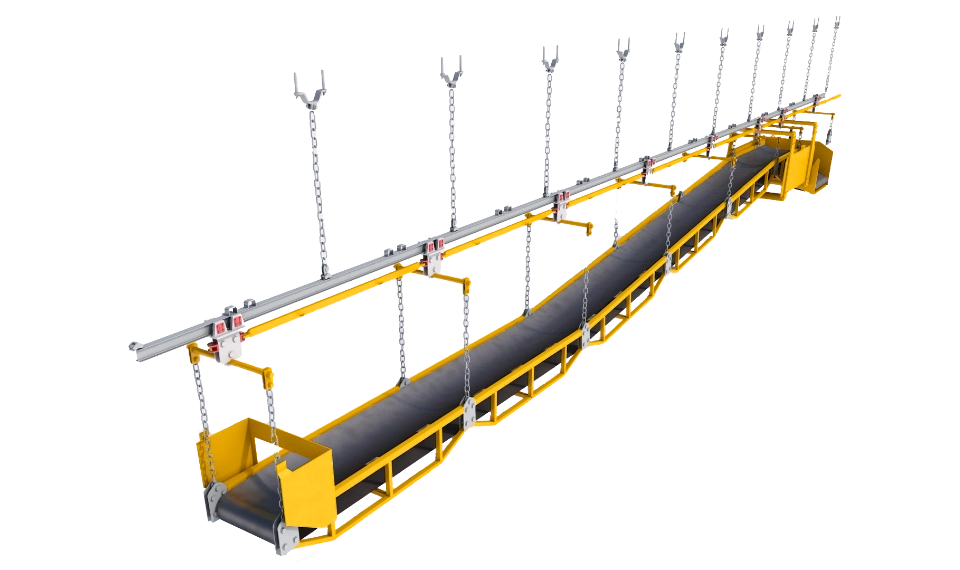

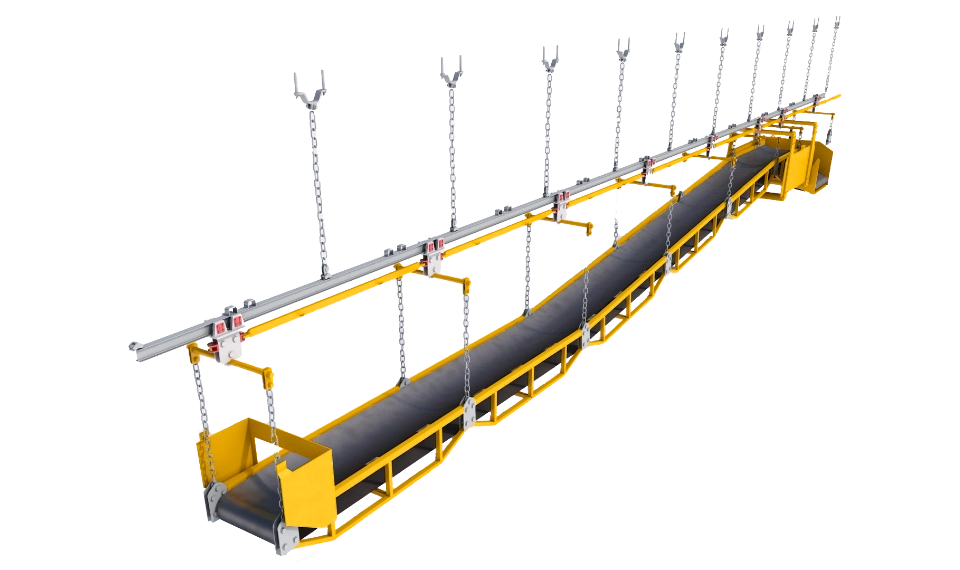

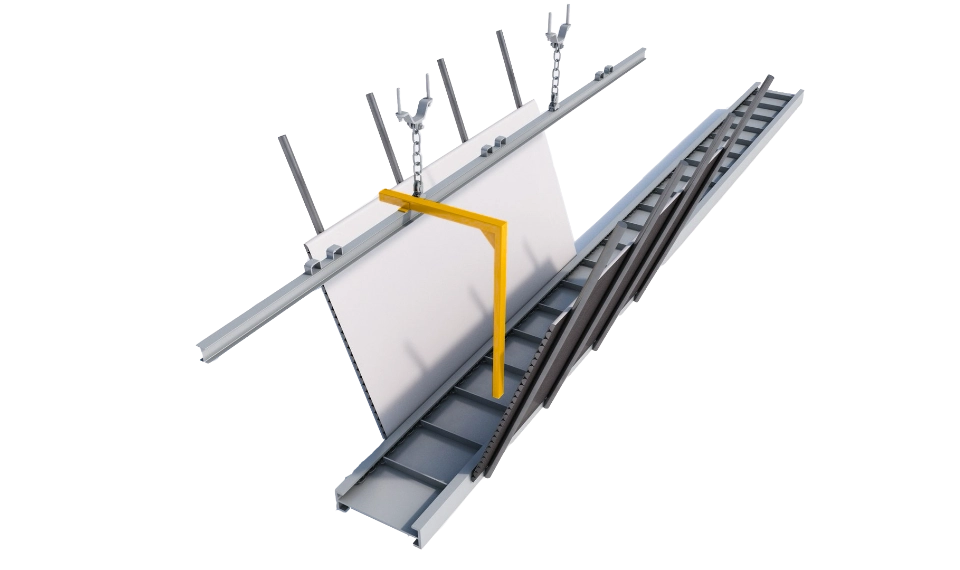

HTR Series – Overhead Suspended Conveyor System

HTR Series is a modular suspended conveyor system designed for confined spaces, tunnels, and underground operations. Its chain-supported belt and overhead rail structure provide flexible installation with zero ground interference, making it ideal for rapid deployment in temporary or hard-to-access areas where traditional conveyor frames are not feasible.

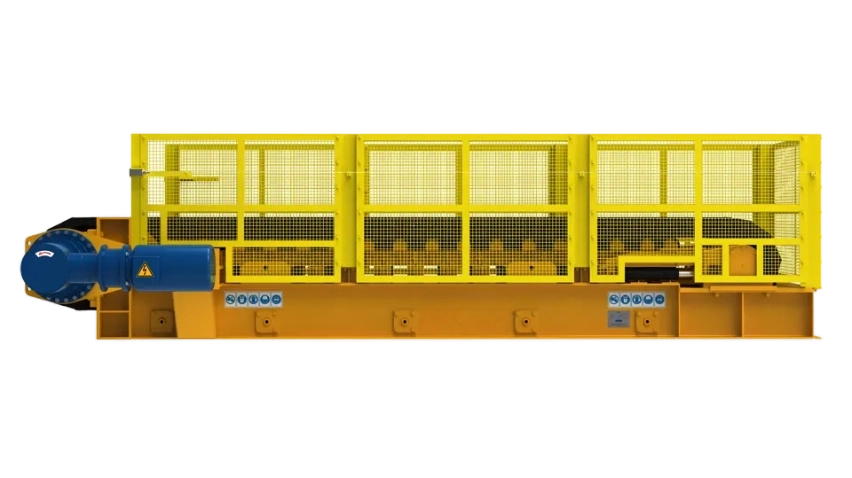

CONVEYOR

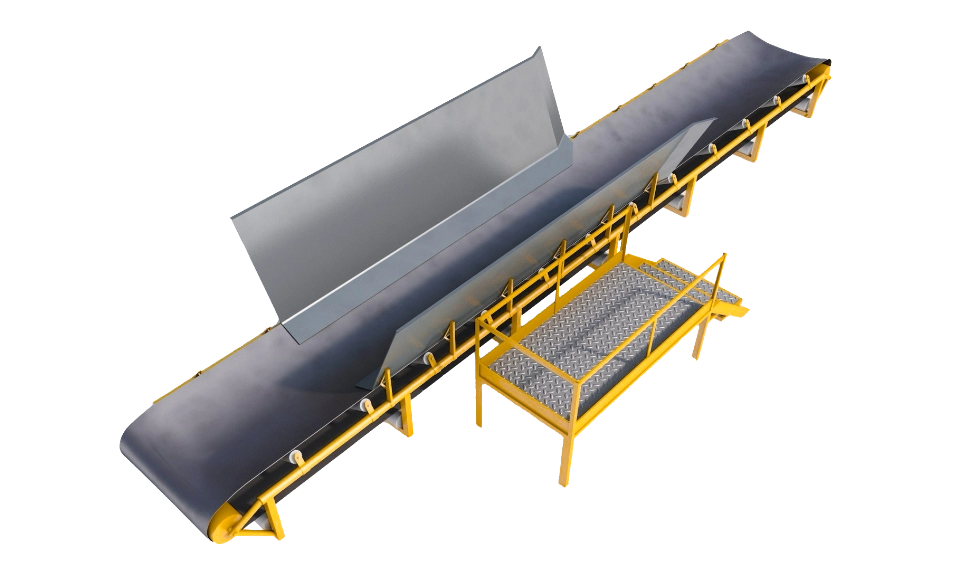

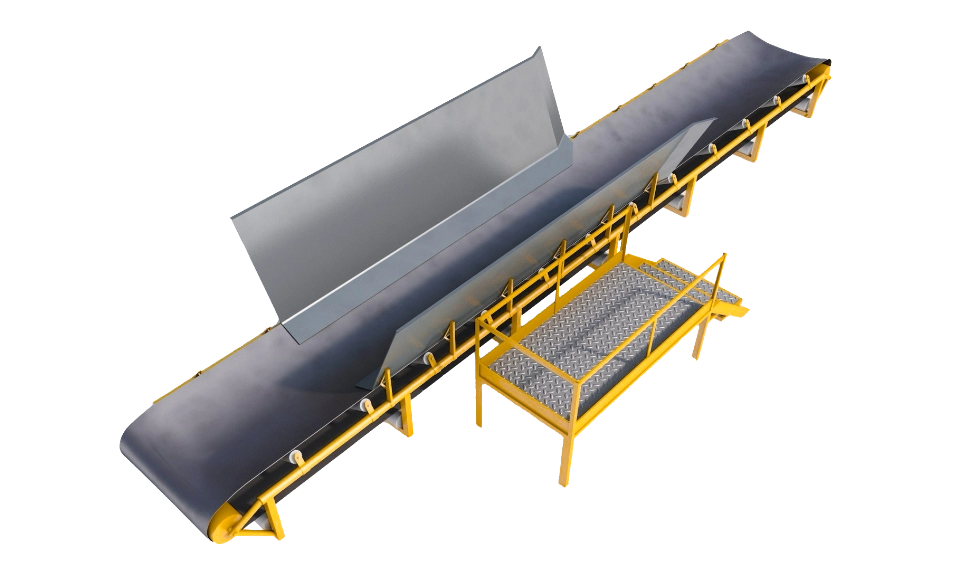

VTX Series – V-Profile Belt Conveyor System

VTX Series conveyors feature a high-capacity V-shaped belt profile supported by angled rollers, ensuring excellent material containment and smooth, centered flow over long distances. Designed for demanding mining and bulk material applications, this system offers superior load stability and optional maintenance platforms for safe operation.

CONVEYOR

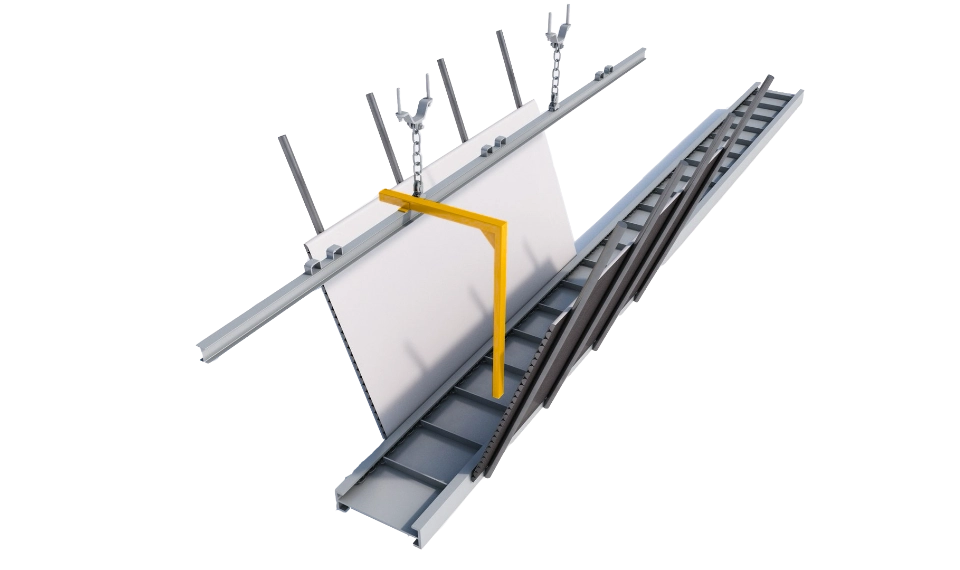

DSK Series – Dust-Proof Belt Conveyor with Cover Rails

DSK Series offers enclosed belt conveying with full-length top covers and sealing skirts, ensuring clean and dust-free transport of fine materials. Designed for ports, open-pit mines, and environmentally sensitive sites, it combines high throughput with robust steel structure and easy-access maintenance systems for reliable long-term operation

CONVEYOR

HTR Series – Overhead Suspended Conveyor System

HTR Series is a modular suspended conveyor system designed for confined spaces, tunnels, and underground operations. Its chain-supported belt and overhead rail structure provide flexible installation with zero ground interference, making it ideal for rapid deployment in temporary or hard-to-access areas where traditional conveyor frames are not feasible.

CONVEYOR

VTX Series – V-Profile Belt Conveyor System

VTX Series conveyors feature a high-capacity V-shaped belt profile supported by angled rollers, ensuring excellent material containment and smooth, centered flow over long distances. Designed for demanding mining and bulk material applications, this system offers superior load stability and optional maintenance platforms for safe operation.

CONVEYOR

DSK Series – Dust-Proof Belt Conveyor with Cover Rails

DSK Series offers enclosed belt conveying with full-length top covers and sealing skirts, ensuring clean and dust-free transport of fine materials. Designed for ports, open-pit mines, and environmentally sensitive sites, it combines high throughput with robust steel structure and easy-access maintenance systems for reliable long-term operation

Feeders

Feeding solutions engineered for performance and reliability

Feeders play a vital role in mineral processing and quarrying circuits by ensuring a consistent material flow and regulating the pace of downstream equipment such as screens and crushers. Reliable feeding is essential to maintaining plant productivity and efficiency.

Our feeders are built to perform in the toughest conditions. Engineered for strength and durability, they are designed to withstand heavy loads, abrasive materials, and harsh environments — ensuring dependable operation even in the most demanding applications.

With minimal maintenance requirements and intuitive operation, feeders are easy to install, commission, and integrate into your existing setup. Backed by Weir Minerals’ global service network, you can count on responsive support and fast parts availability wherever your site is located.

Choose our feeders for robust design, smooth performance, and long-term dependability — helping you keep your plant running efficiently and consistently.

APRON FEEDER

MAF Series Apron Feeder

MAF series apron feeders deliver reliable material handling in the toughest conditions, including sharp, sticky, or hot materials. Ideal for primary, secondary, and tertiary applications, they feature a crawler undercarriage, abrasion-resistant pans, and heavy-duty components for high performance with minimal maintenance.

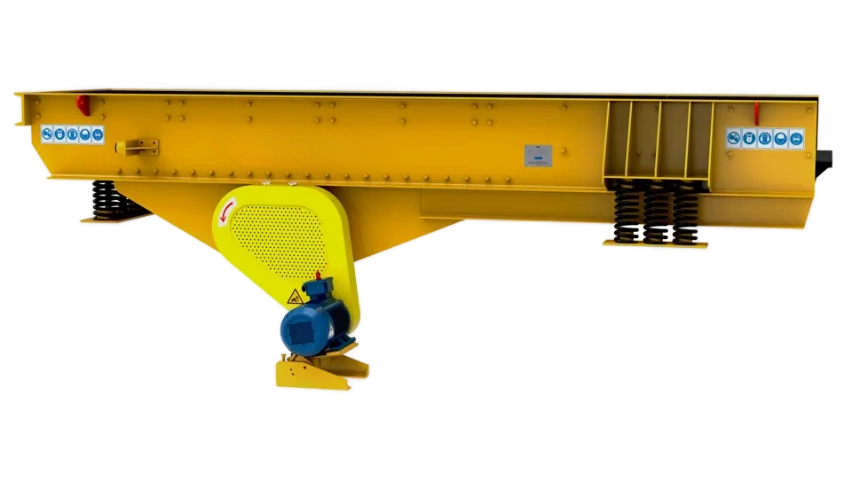

GRIZZLY FEEDER

GF Series Vibrating Grizzly Feeder

GF series vibrating grizzly feeders are built to handle heavy surge loads and deliver a consistent material flow to crushers. Ideal for primary applications, they feature rugged construction, adjustable linear motion, oil-lubricated shafts, and grizzly sections to pre-screen undersized material for efficient downstream processing

PAN FEEDER

PF Series Vibrating Pan Feeder

PF Series vibrating pan feeders deliver accurate, controlled material flow in mining, aggregates, and recycling applications. Featuring a rugged steel frame, abrasion-resistant liners, and dual out-of-balance motors, they provide reliable performance in tough environments with adjustable stroke and optional suspended mounting.

APRON FEEDER

MAF Series Apron Feeder

MAF series apron feeders deliver reliable material handling in the toughest conditions, including sharp, sticky, or hot materials. Ideal for primary, secondary, and tertiary applications, they feature a crawler undercarriage, abrasion-resistant pans, and heavy-duty components for high performance with minimal maintenance.

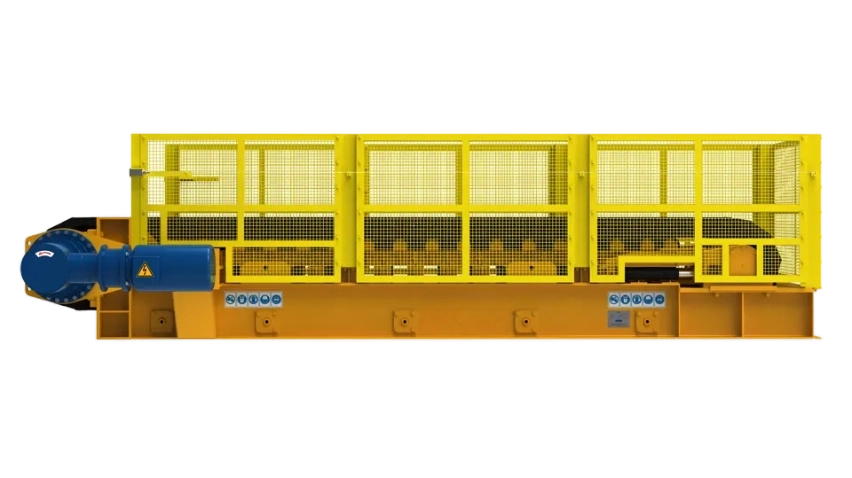

GRIZZLY FEEDER

GF Series Vibrating Grizzly Feeder

GF series vibrating grizzly feeders are built to handle heavy surge loads and deliver a consistent material flow to crushers. Ideal for primary applications, they feature rugged construction, adjustable linear motion, oil-lubricated shafts, and grizzly sections to pre-screen undersized material for efficient downstream processing

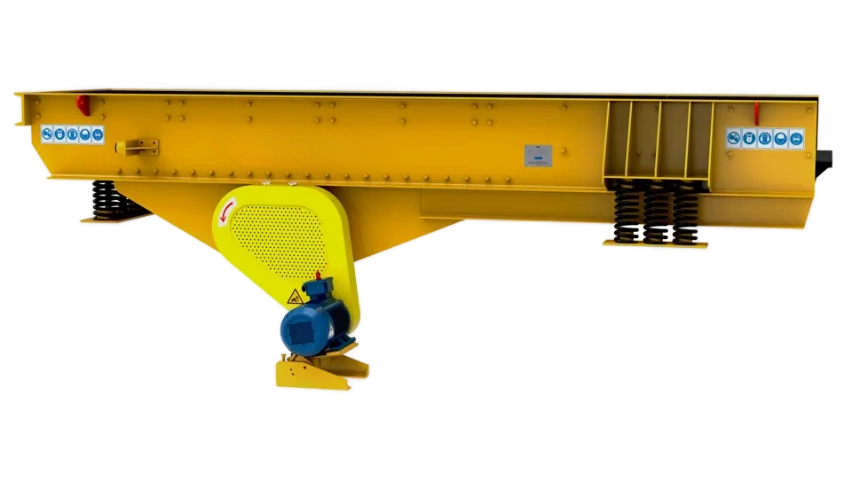

PAN FEEDER

PF Series Vibrating Pan Feeder

PF Series vibrating pan feeders deliver accurate, controlled material flow in mining, aggregates, and recycling applications. Featuring a rugged steel frame, abrasion-resistant liners, and dual out-of-balance motors, they provide reliable performance in tough environments with adjustable stroke and optional suspended mounting.

Mills

Energy-efficient grinding solutions for mineral processing

Mills play a critical role in reducing crushed ore into fine particles suitable for further separation and recovery. At Minerza, we offer a comprehensive range of grinding technologies built for durability, process stability, and continuous operation under heavy loads.

Ball mills. Versatile wet or dry grinding of ores, cement clinker, and bulk materials

SAG mills (Semi-Autogenous). High-throughput primary grinding using a combination of ore and grinding media

Vertical tower mills. Compact, energy-efficient grinding for fine and ultra-fine applications

High Pressure Grinding Rolls (HPGR). Efficient size reduction through inter-particle compression, enhancing downstream recovery and lowering energy consumption.

All mills are equipped with reinforced shells, abrasion-resistant liners, efficient drive systems, and customizable discharge solutions. We support both trunnion and peripheral discharge types and can integrate mills into closed grinding circuits with classifiers and hydrocyclones.

Minerza supplies complete mills as well as individual components such as shells, trunnions, heads, gears, liners, and bearing assemblies — including custom manufacturing based on client drawings and specifications.

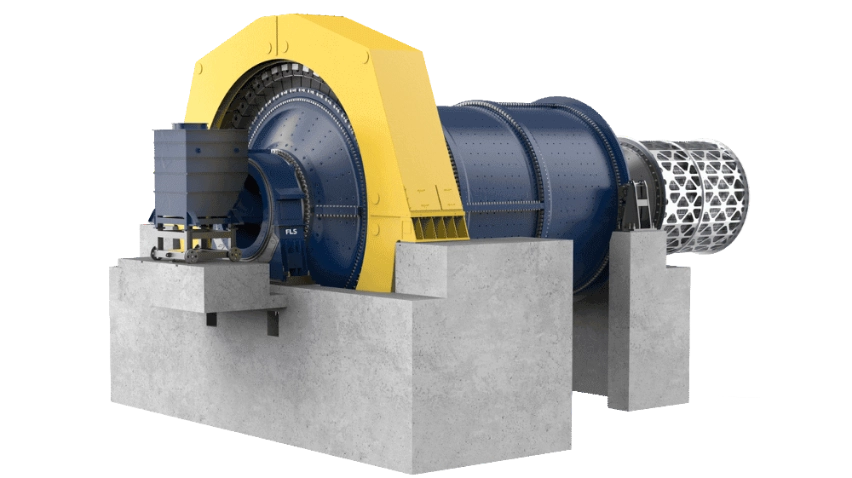

BALL MILL

MBX Series Ball Mill

The MBX Series ball mills are built for heavy-duty grinding of hard and abrasive materials. With optimized liners and energy-efficient drive systems, they offer extended service life and precision in ore processing, cement production, and other demanding operations.

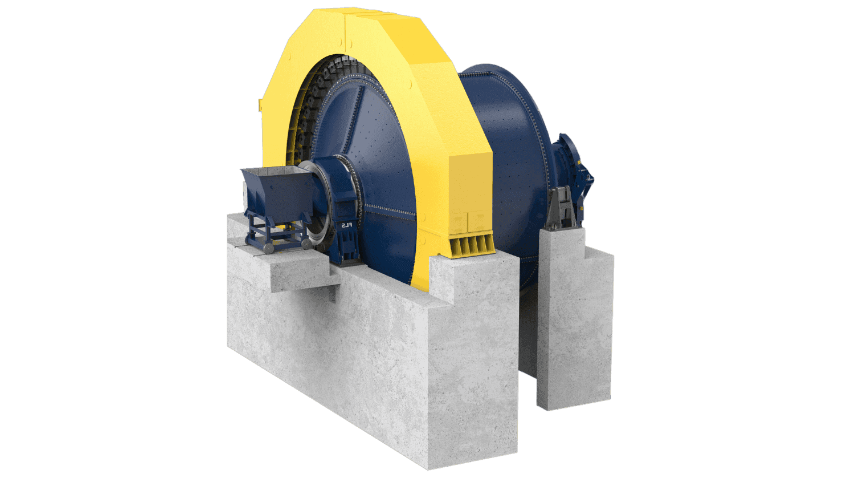

BALL MILL

SGX Series SAG Mill

The SGX Series SAG mill delivers high-throughput grinding for large-scale mining operations. Using both ore and steel balls as grinding media, it’s ideal for primary processing of hard ores like gold, copper, and iron. With low energy consumption and robust design, it ensures reliable performance and reduced operating costs.

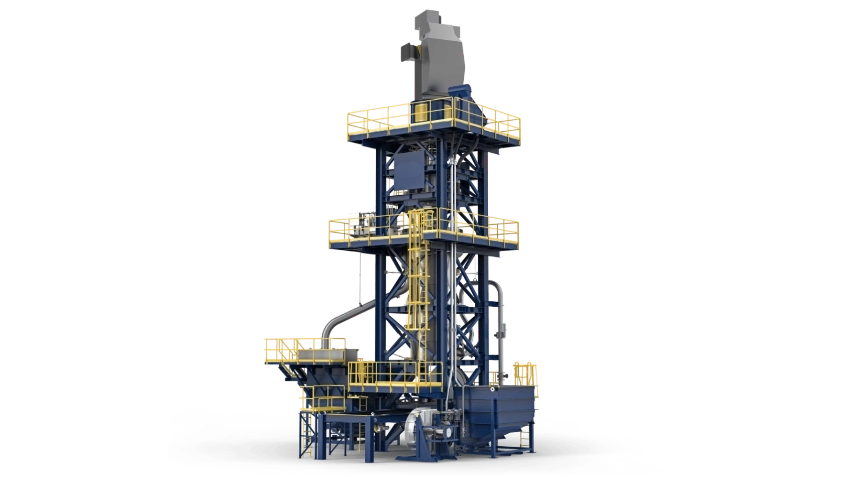

TOWER MILL

TXP Series Tower Mill

The TXP Series tower mill is a vertical, energy-efficient solution for fine and ultra-fine grinding below 30 microns. Using ceramic media and a modular impeller system, it delivers high-intensity attrition grinding with low energy consumption. Ideal for mineral processing where precision, flexibility, and efficiency are critical.

TOWER MILL

TXP Series Tower Mill

The TXP Series tower mill is a vertical, energy-efficient solution for fine and ultra-fine grinding below 30 microns. Using ceramic media and a modular impeller system, it delivers high-intensity attrition grinding with low energy consumption. Ideal for mineral processing where precision, flexibility, and efficiency are critical.

Ash Handling Systems

Minerza offers a full portfolio of advanced ash handling systems designed for efficient, reliable, and environmentally compliant bottom ash removal in thermal power plants and industrial boilers. Our solutions cover both wet and dry technologies, ensuring flexibility for retrofit and new installations alike.

From submerged flight conveyors that combine water-based quenching with mechanical extraction, to fully dry systems based on vibrating or pneumatic transport, each solution is engineered to match specific operational needs, boiler configurations, and environmental standards.

Our lineup includes:

– SFG Series: Submerged flight conveyors for continuous water-cooled ash removal.

– VBR Series: Vibrating deck conveyors with fluidized beds for 100% dry discharge and superior heat recovery.

– PNM Series: Pneumatic vacuum systems for long-distance dry ash transport with zero water usage.

Minerza ash handling systems are built for durability, low maintenance, and maximum process efficiency — helping plants reduce emissions, save water, and comply with modern ash management regulations.

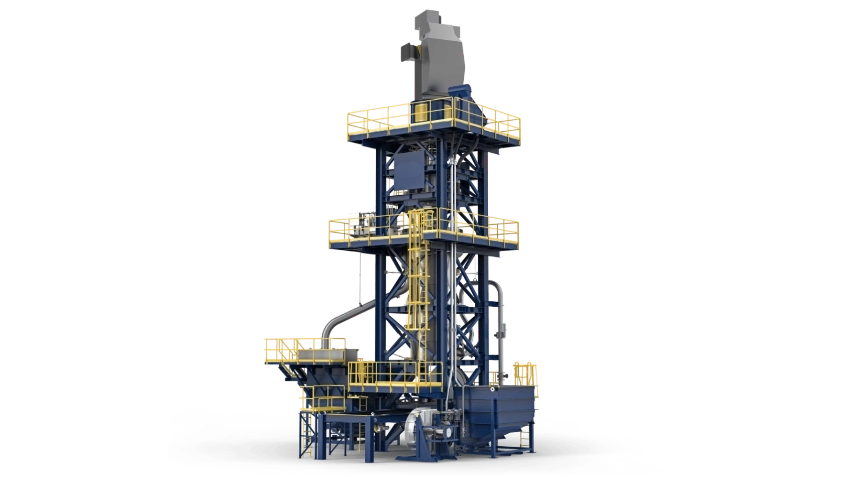

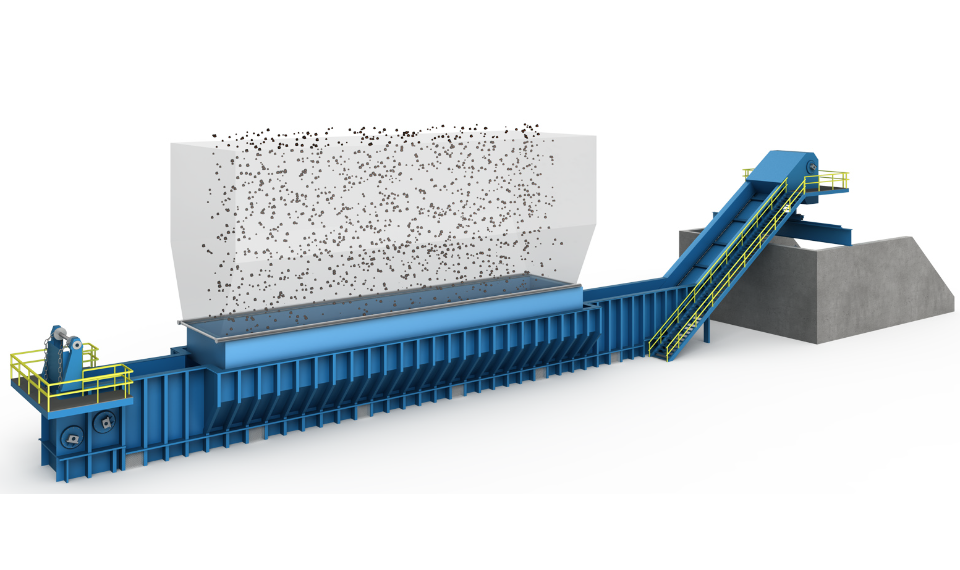

ASH HANDLING SYSTEM

SFG Series – Submerged Flight Conveyor

SFG Series conveyors ensure continuous bottom ash removal using a submerged scraper chain. Hot ash is cooled in a water-filled trough, conveyed and dewatered before discharge. The system delivers low water usage, high reliability, and minimal maintenance in thermal power applications.

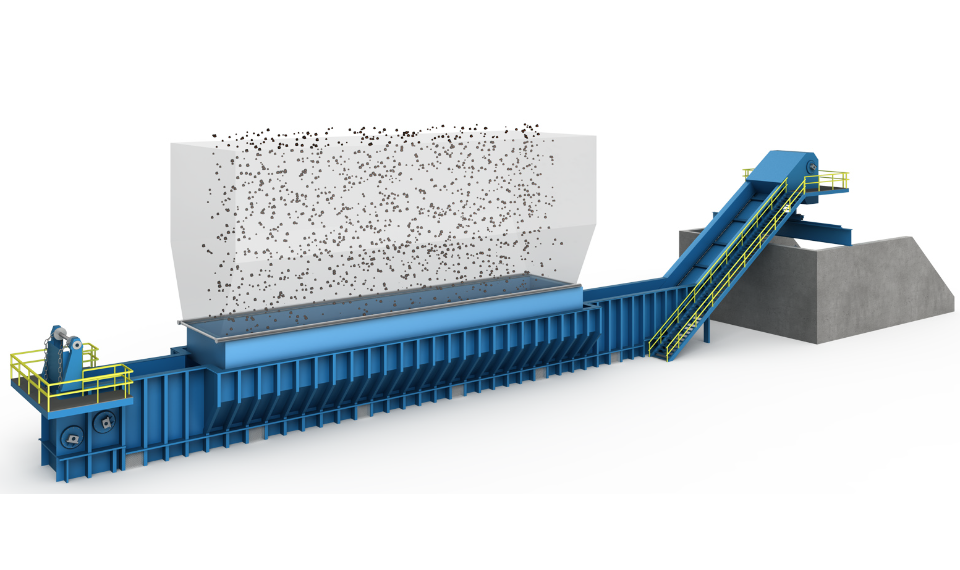

ASH HANDLING SYSTEM

VBR Series – Vibrating Dry Bottom Ash Conveyor

VBR Series provides continuous dry ash removal with a vibrating deck under the boiler. No moving parts or water are used, reducing maintenance and energy loss. Fluidized ash bed boosts combustion and heat recovery, making this a durable, efficient, and fully dry solution for modern power generation.

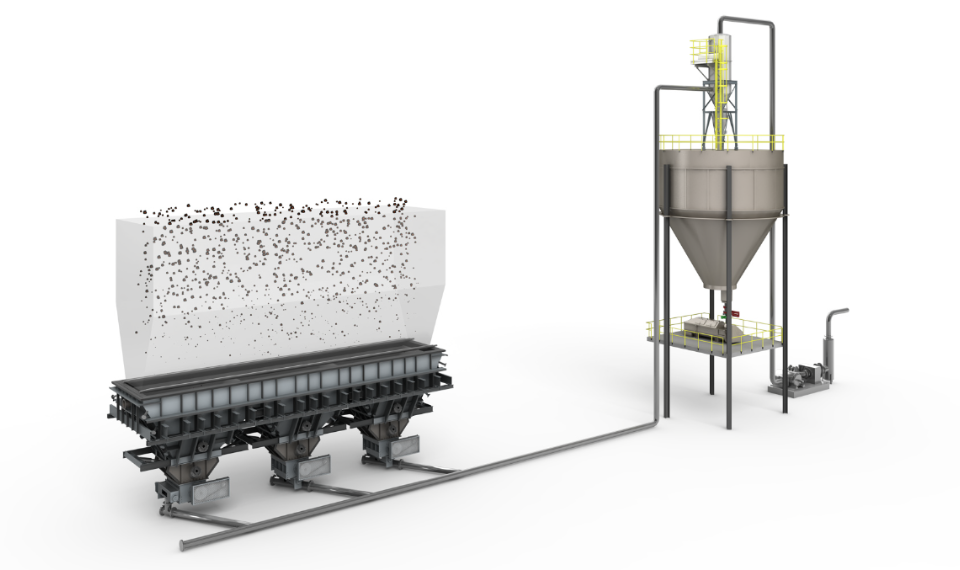

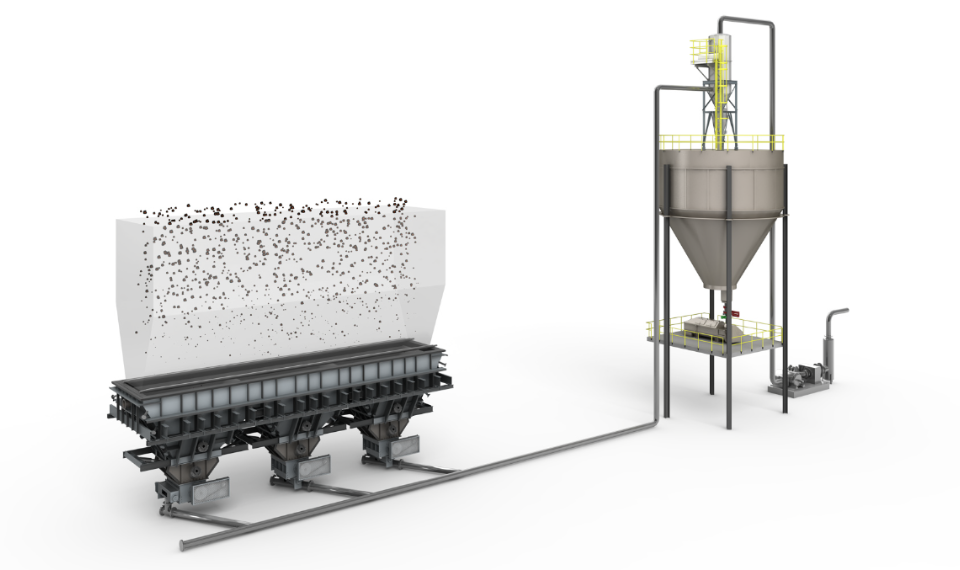

ASH HANDLING SYSTEM

PNM Series – Pneumatic Dry Ash Conveyor

PNM Series provides 100% dry bottom ash removal using a vacuum-based pneumatic system. Ash is cooled, crushed, and conveyed from a dry hopper to a storage silo with no water required. This low-maintenance solution reduces cost, improves safety, and ensures reliable long-term ash handling performance.

ASH HANDLING SYSTEM

SFG Series – Submerged Flight Conveyor

SFG Series conveyors ensure continuous bottom ash removal using a submerged scraper chain. Hot ash is cooled in a water-filled trough, conveyed and dewatered before discharge. The system delivers low water usage, high reliability, and minimal maintenance in thermal power applications.

ASH HANDLING SYSTEM

VBR Series – Vibrating Dry Bottom Ash Conveyor

VBR Series provides continuous dry ash removal with a vibrating deck under the boiler. No moving parts or water are used, reducing maintenance and energy loss. Fluidized ash bed boosts combustion and heat recovery, making this a durable, efficient, and fully dry solution for modern power generation.

ASH HANDLING SYSTEM

PNM Series – Pneumatic Dry Ash Conveyor

PNM Series provides 100% dry bottom ash removal using a vacuum-based pneumatic system. Ash is cooled, crushed, and conveyed from a dry hopper to a storage silo with no water required. This low-maintenance solution reduces cost, improves safety, and ensures reliable long-term ash handling performance.