PNM Series – Pneumatic Dry Ash Conveyor

PNM Series – Pneumatic Dry Ash Conveyor

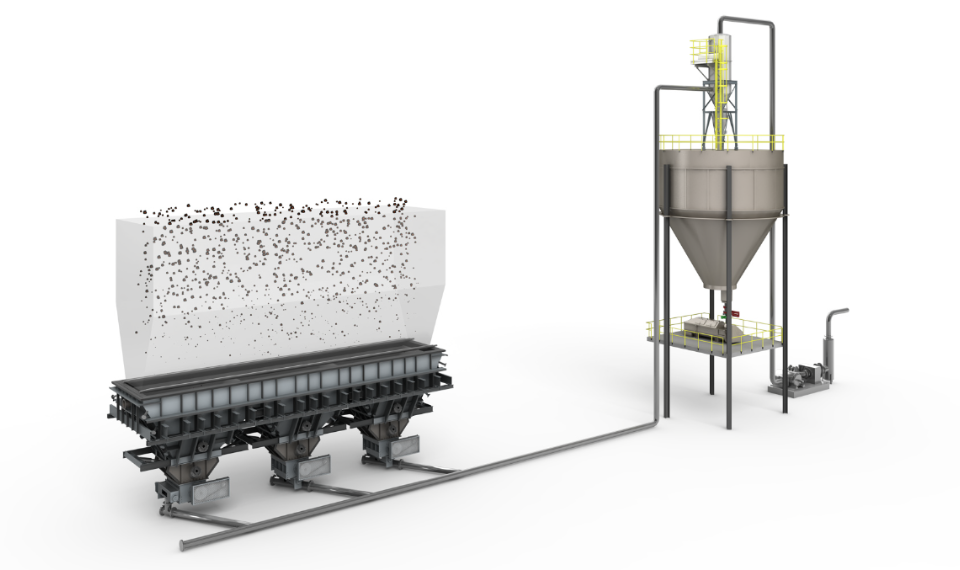

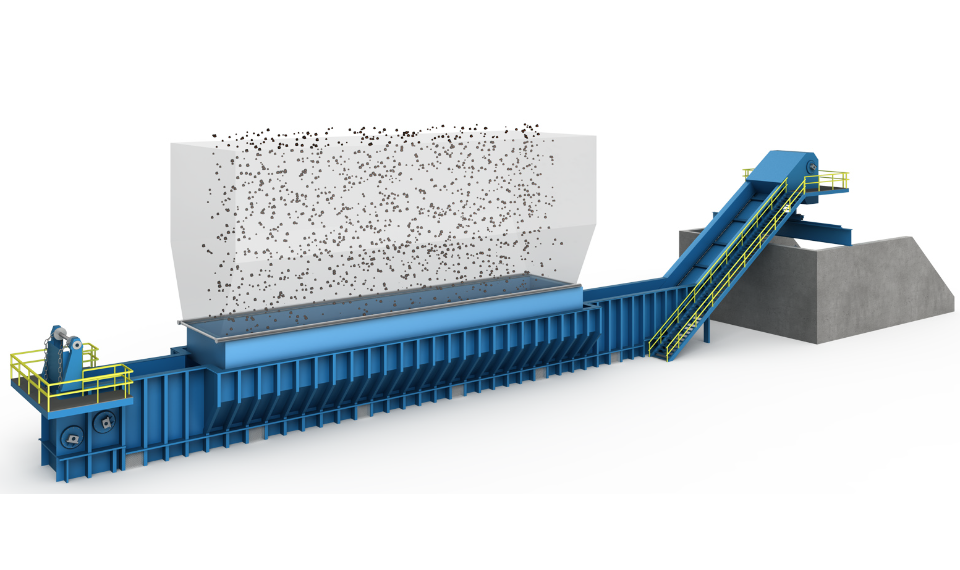

PNM Series pneumatic ash conveyors offer a 100% dry method of bottom ash handling using vacuum-driven transport. Based on time-proven principles, the system stores dry ash in a refractory-lined hopper beneath the boiler. Percolating air cools and conditions the ash while aiding combustion of unburned particles and protecting downstream equipment. Crushed ash is then pneumatically conveyed to a storage silo before final unloading via belt or gravity. With no water required, PNM systems minimize operational costs, reduce complexity, and are ideal for facilities prioritizing clean, dry, and efficient ash management.

Specifications:

Ash temperature: up to 800°C

Conveying type: vacuum pneumatic (negative pressure)

Ash storage: refractory-lined hopper

Air cooling flow: 300–1200 m³/h

Ash particle size: up to 30 mm (pre-crushed)

Conveying distance: up to 200 m

Power requirement: 11–30 kW

Water usage: 0 L — fully dry system

Discharge method: belt conveyor or gravity

Silo compatibility: standard or custom dry silos

Suitable for retrofits and new boiler installations