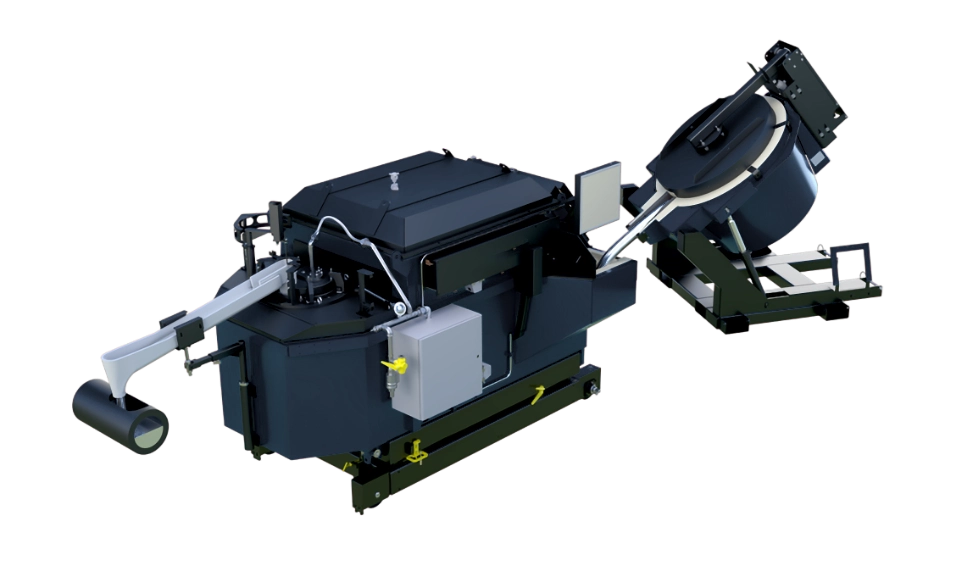

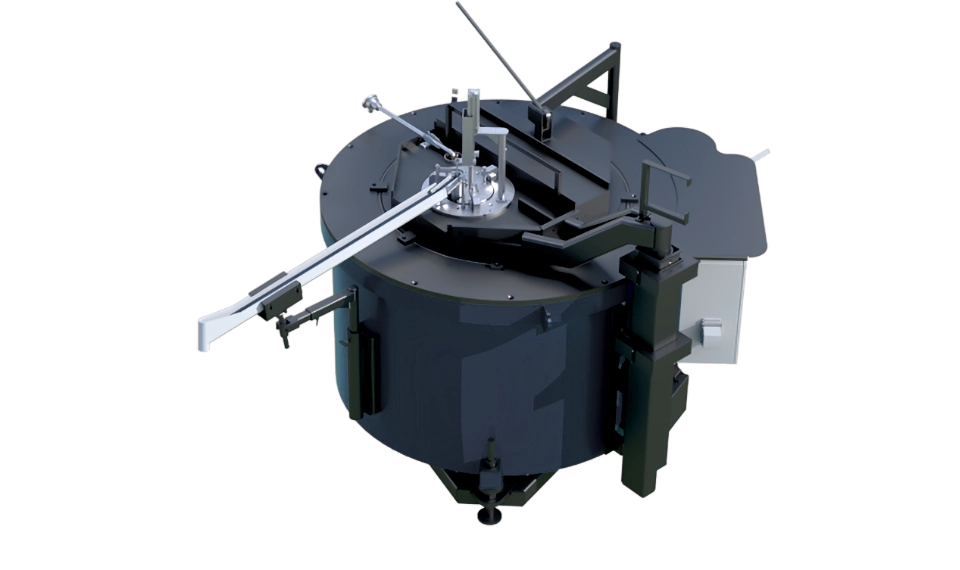

STE Series – Aluminium Dosing Furnace

STE Series – Aluminium Dosing Furnace

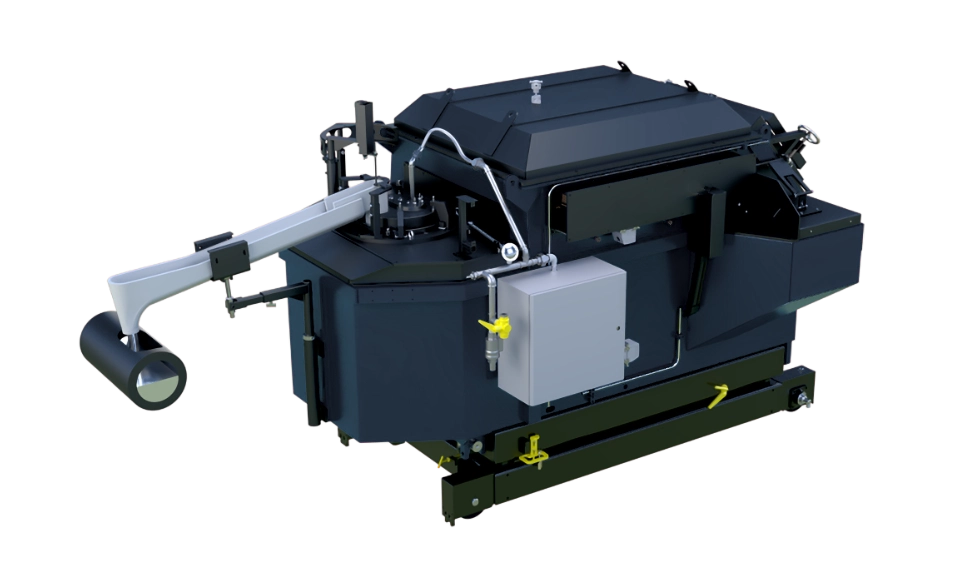

STE Dosotherm® is a high efficiency-dosing furnace featuring our unique, patented dosing system, where only the ceramic dosing unit is pressurized for dosing metal.

STE are from the automotive industry the preferred dosing technology for high quality aluminum parts like structure parts.

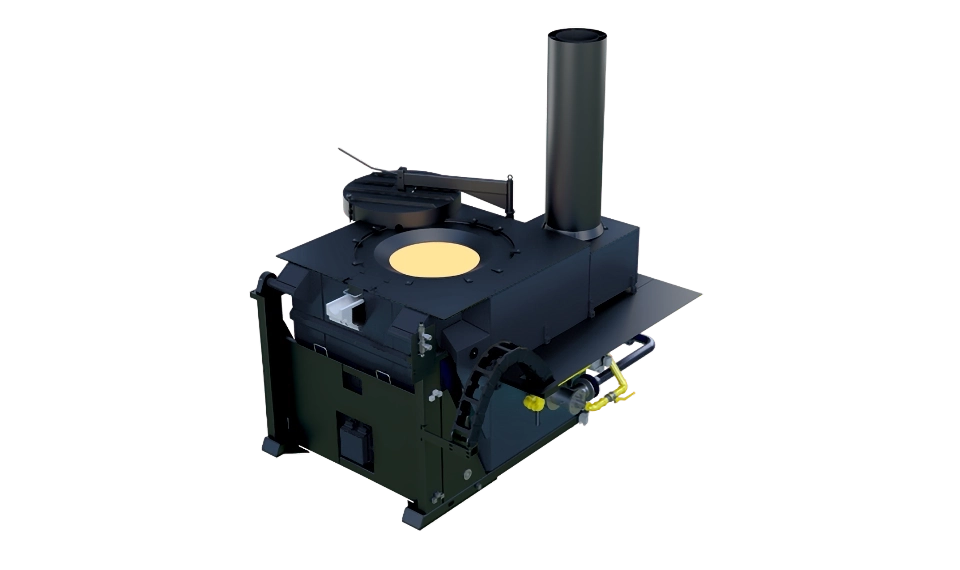

The furnace gives an extremely good metal quality because of the protected atmosphere and low energy consumption, and the best on the market dosing accuracy lower than ±1%.

Effective process – increase productivity to maximum output because faster cycle time / dosing time, filling and cleaning the dosing furnace during production and with the newly designed intelligent PLC controlling system will help reduce unplanned production stop.

Due to the low volume required, the use of nitrogen or argon as the pressure medium is practical, resulting in extremely clean metal.

All these benefits can help to reduce the total cost from 40% to 80%.

-

Ensuring effective process for high quality aluminium like for structure part

-

Dosing accuracy better than +/- 1%

-

Faster dosing, cycle time 50%

-

Extremely energy and CO₂ efficient by saving 40 up to more than 80%

-

Increase productivity with the intelligent control system – less production stop

-

Metal temperature accuracy of +/- 1°C

-

Extremely low air consumption for dosing

-

Reduce yearly maintenance cost up to 50%

-

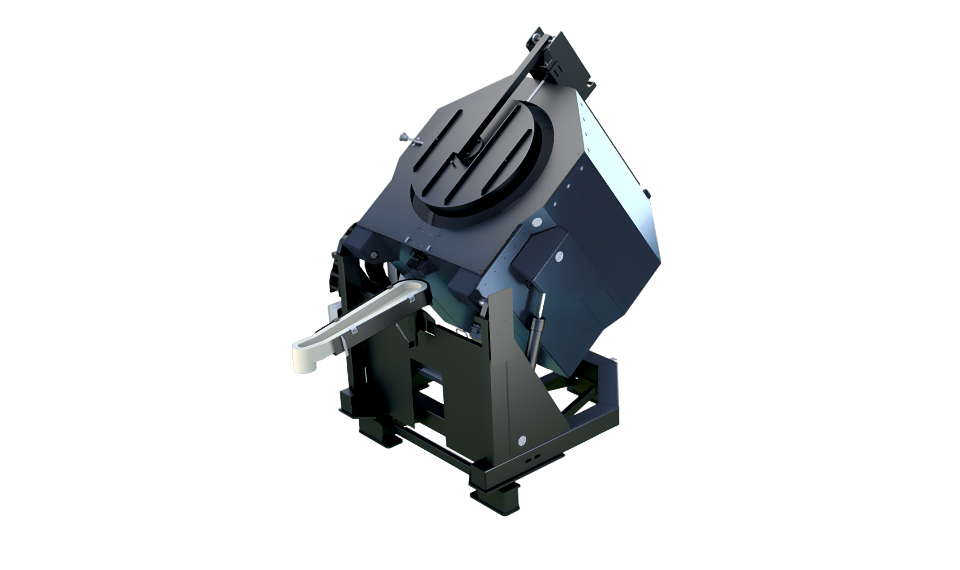

Better metal quality by using filter under the dosing pump

-

Increase safety with lower fill height – same or lower than the shot sleeve height

-

Providing strong, local customer support

-

Option: operate with degassing stone and protecting gas for dosing