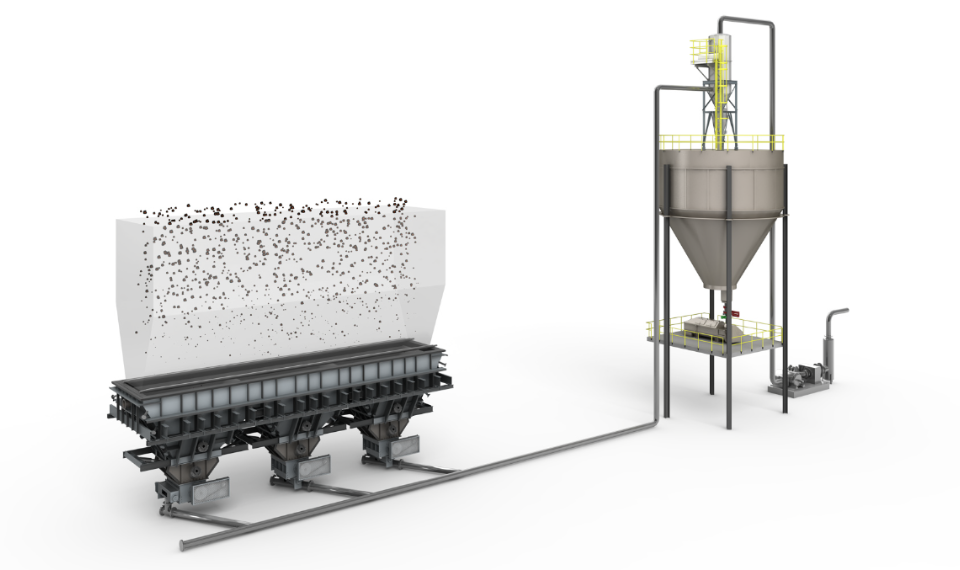

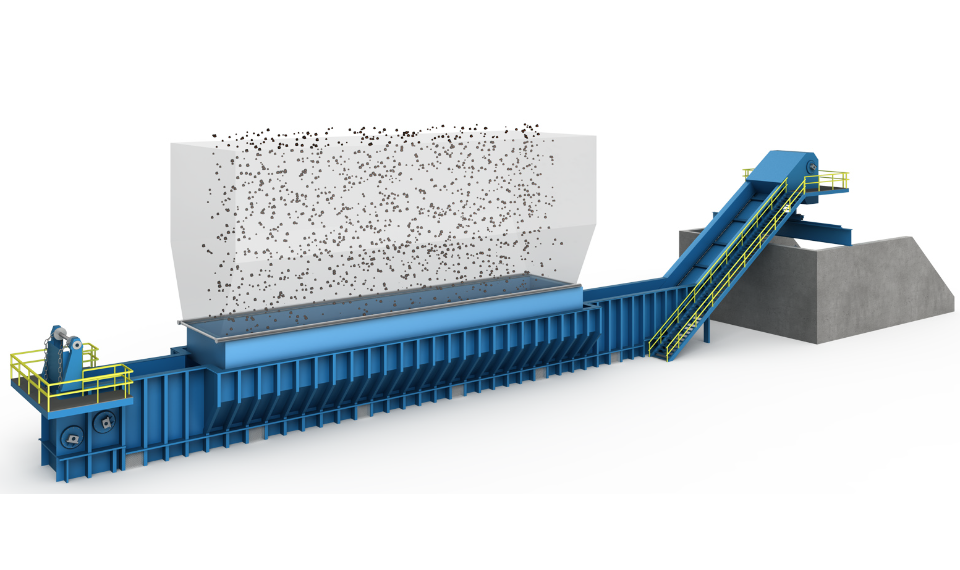

VBR Series – Vibrating Dry Bottom Ash Conveyor

VBR Series – Vibrating Dry Bottom Ash Conveyor

VBR Series vibrating conveyors represent the latest dry bottom ash handling technology, eliminating the need for water or ponds. The system uses a vibrating deck under the boiler to gently move ash to a crusher, then to a secondary conveyor. No moving mechanical parts exist under the boiler, reducing wear and maintenance while improving heat recovery. A fluidized vibrating bed allows combustion of unburned ash and forces cooling air upward, boosting boiler efficiency and extending system life. Ideal for modern power plants seeking a 100% dry, energy-efficient solution with minimal environmental impact.

Specifications:

Ash temperature: up to 1000°C

Ash throughput: up to 12 t/h

Deck type: alloy steel vibrating trough

Drive type: electromechanical vibrators

Vibration amplitude: 3–6 mm

Frequency: 14–20 Hz

Cooling air flow: up to 1500 m³/h

Inclination: 0–10°

Power requirement: 7.5–22 kW

Maintenance interval: 1500+ hours

No submerged components or water usage