SFG Series – Submerged Flight Conveyor

SFG Series – Submerged Flight Conveyor

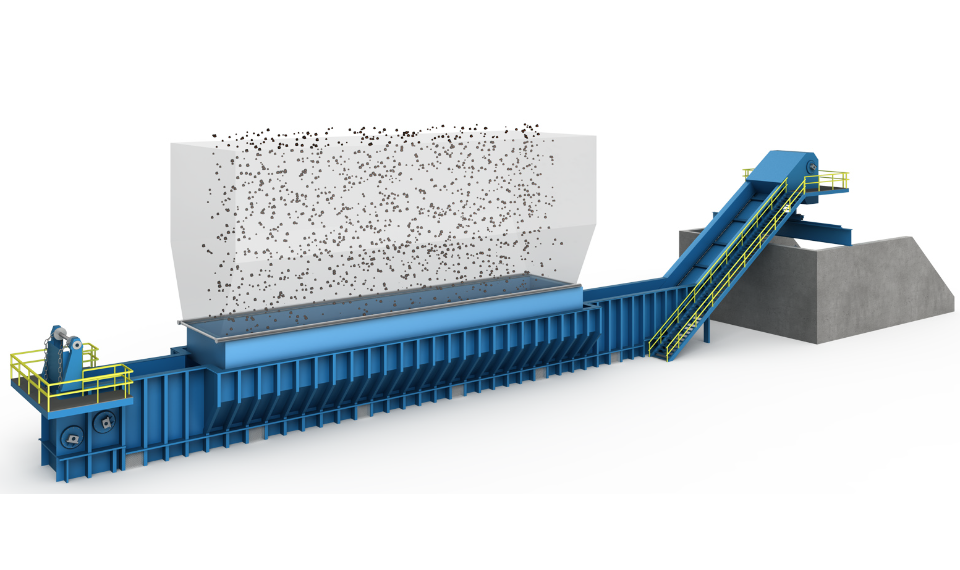

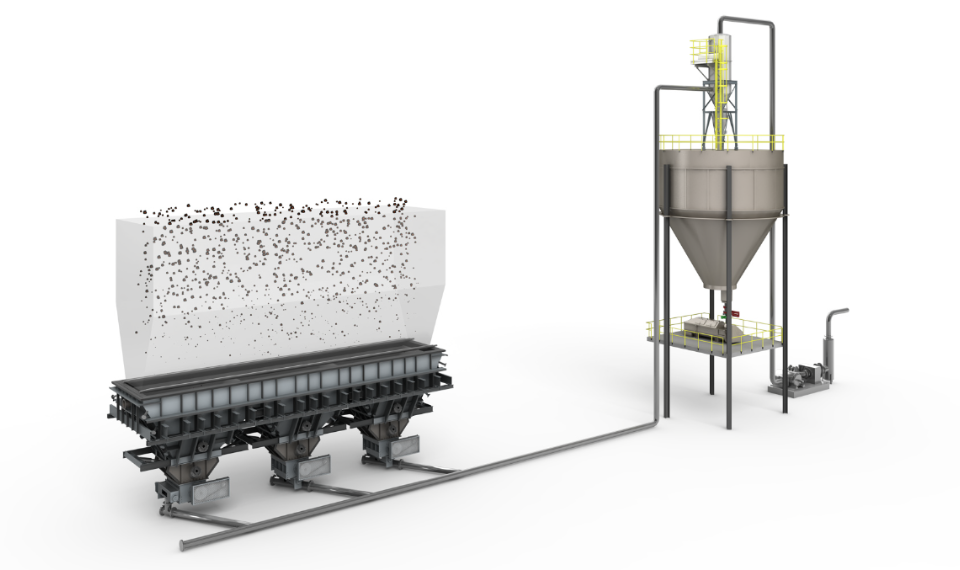

SFG Series submerged flight conveyors are designed for continuous bottom ash removal in thermal power plants and industrial boiler systems. These systems replace conventional wet sluice conveyors by utilizing a submerged mechanical chain with attached scraper flights that operate within a water-filled trough. As hot ash falls from the boiler, it is immediately quenched and cooled in the submerged chamber. The scraper flights push the ash along the trough and up an inclined dewatering section, where water drains off and the ash is discharged into a bunker or truck chute. This system allows for low-maintenance, energy-efficient operation and significantly reduces both water consumption and environmental impact.

Specifications:

Operating temperature: up to 1000°C ash input

Chain speed: 0.03–0.15 m/s

Ash throughput: up to 10 t/h

Trough material: carbon steel with anti-corrosion coating

Water volume: 2–5 m³ depending on size

Scraper spacing: 500 mm

Incline angle: 15–25°

Power requirement: 5.5–15 kW

Maintenance cycle: 1,000+ operating hours

Recommended applications: coal-fired power plants, biomass boilers, incinerators