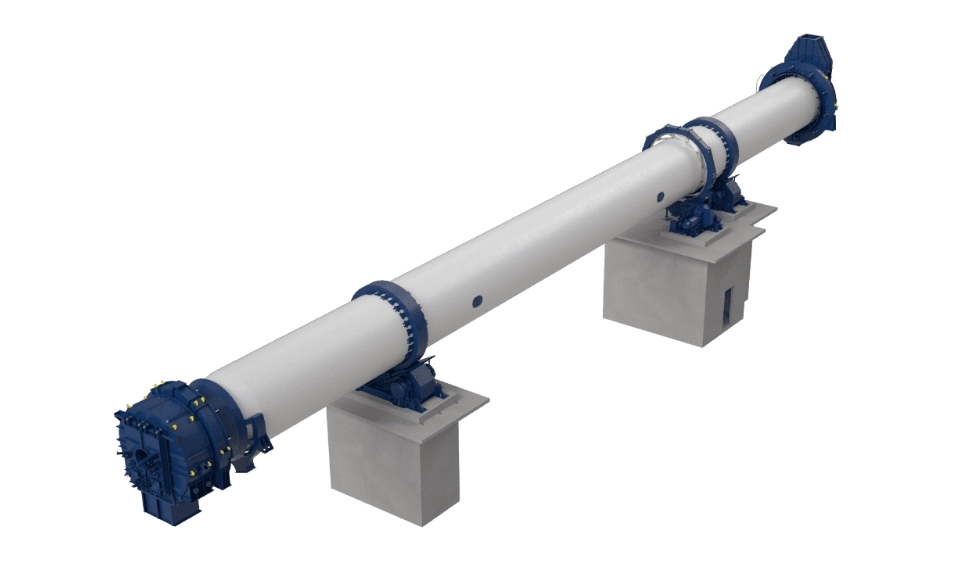

KRN Series – Gear-Drive Rotary Kiln

KRN Series – Gear-Drive Rotary Kiln

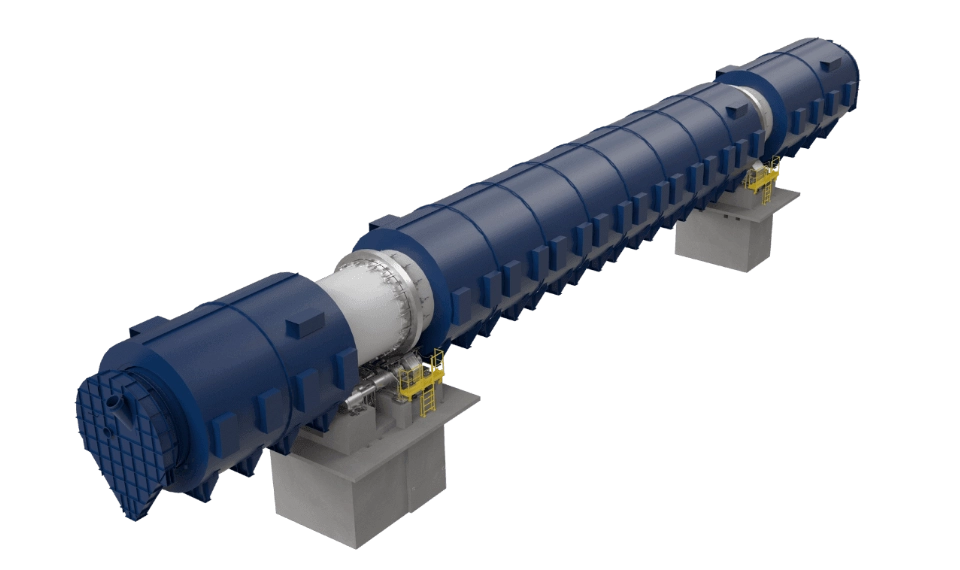

The KRN Series rotary kiln is a heavy-duty, gear-driven thermal processing system designed for the continuous treatment of bulk materials at high temperatures. Built for demanding applications in the cement, lime, and mineral processing industries, it features a central or peripheral gear drive system that ensures reliable torque transmission and stable rotation even under extreme thermal and mechanical stress.

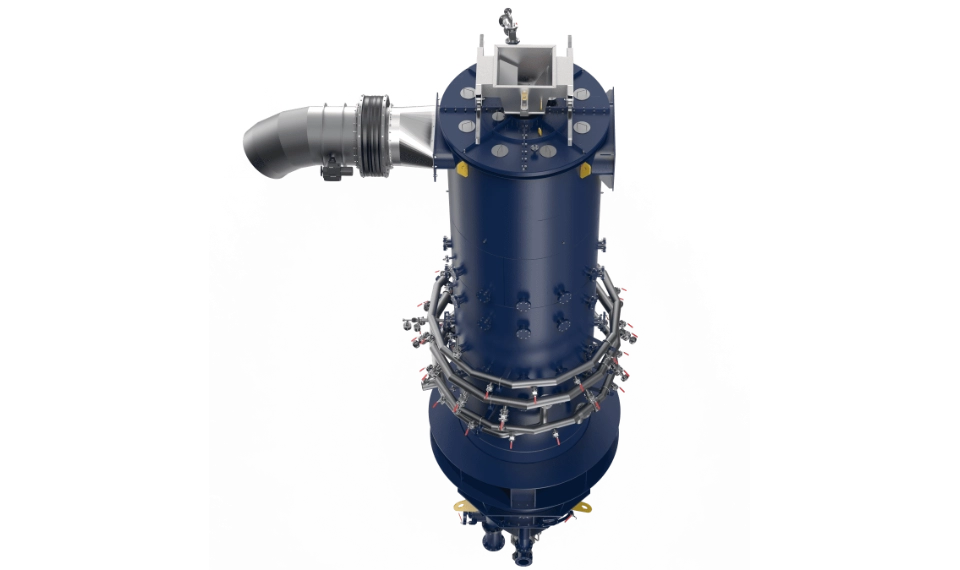

This series is fully customizable with modular refractory linings, flexible feed arrangements, and advanced sealing systems to minimize air leakage and heat loss. It supports fuel versatility (including gas, oil, and alternative fuels) and is optimized for maximum thermal efficiency and precise control of residence time, critical for achieving desired material transformations such as calcination, sintering, and phase change.

Optional smart automation systems allow real-time monitoring of temperature profiles, rotational speed, and material flow, ensuring consistent product quality and extended kiln life. Integration with dust collection and flue gas treatment units enables compliance with modern environmental standards.

Key Specifications:

• Kiln diameter: up to 6.0 m

• Kiln length: up to 100 m

• Operating temperature: up to 1450 °C

• Drive system: central or peripheral gear drive

• Shell material: high-strength carbon or alloy steel

• Lining options: castable, brick, or modular refractory systems

• Applications: cement clinker production, quicklime, kaolin, bauxite, metallurgical slag recovery

• Fuel types: natural gas, diesel, coal, alternative fuels

• Optional features: flue gas coolers, clinker coolers, process control panels