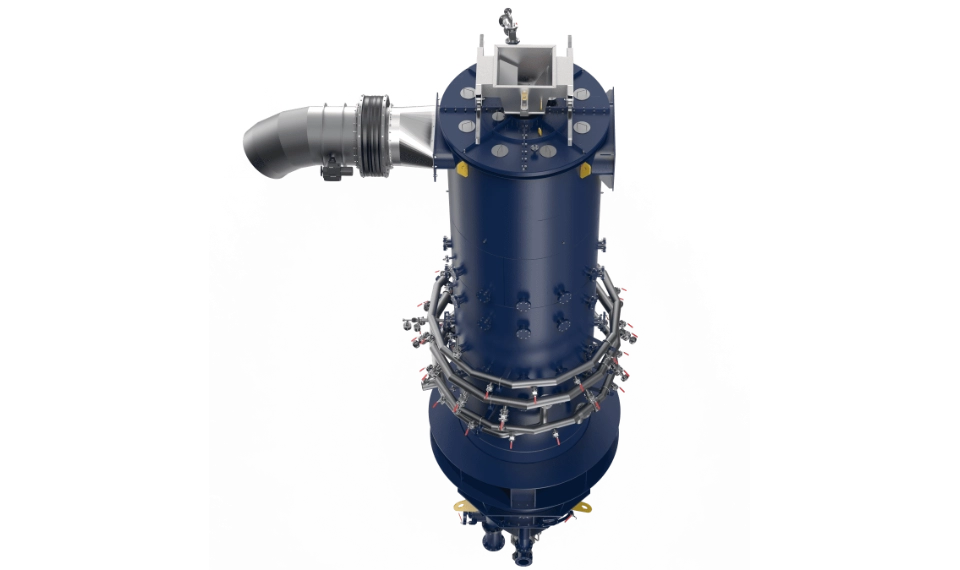

KSH Series – High-Temperature Shaft Kiln

KSH Series – High-Temperature Shaft Kiln

The KSH Series shaft kiln is a compact, vertical thermal processing unit engineered for high-temperature operations such as lime calcination, dolomite processing, and refractory material production. Unlike rotary kilns, shaft kilns operate in a counter-current flow configuration, where preheated combustion gases rise to meet the descending raw material, achieving exceptional thermal efficiency and fuel savings.

This kiln type excels in continuous, high-throughput applications, delivering uniform product quality with minimal energy consumption. Its robust refractory lining, high-performance burner systems, and precise control over air and fuel distribution make it a reliable solution for demanding industrial environments.

Ideal for metallurgical, chemical, and construction materials industries, the KSH shaft kiln ensures stable performance, low emissions, and long service life. Modular designs allow for easy integration into existing or greenfield production lines.

Key Specifications:

• Operating temperature: up to 2000 °C

• Kiln diameter: 1–4 meters

• Typical output: 100–800 t/day

• Fuel: natural gas, coal, petroleum coke, biomass

• Application: lime, dolomite, magnesite, cement clinker

• Burner zones: single or multi-level

• Emission control: low-NOx burners, gas scrubbers optional