SGT Series – Aluminium Shaft Furnace

SGT Series – Aluminium Shaft Furnace

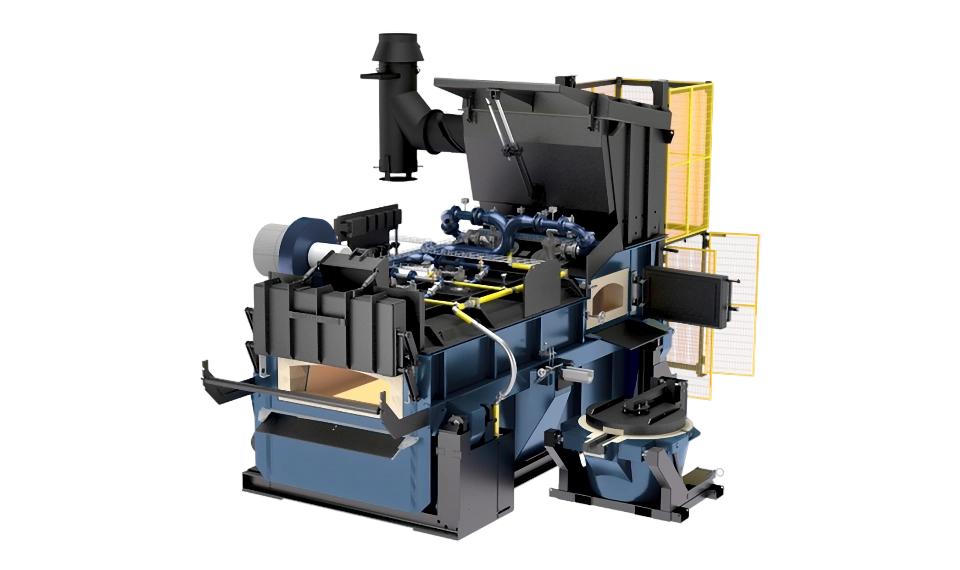

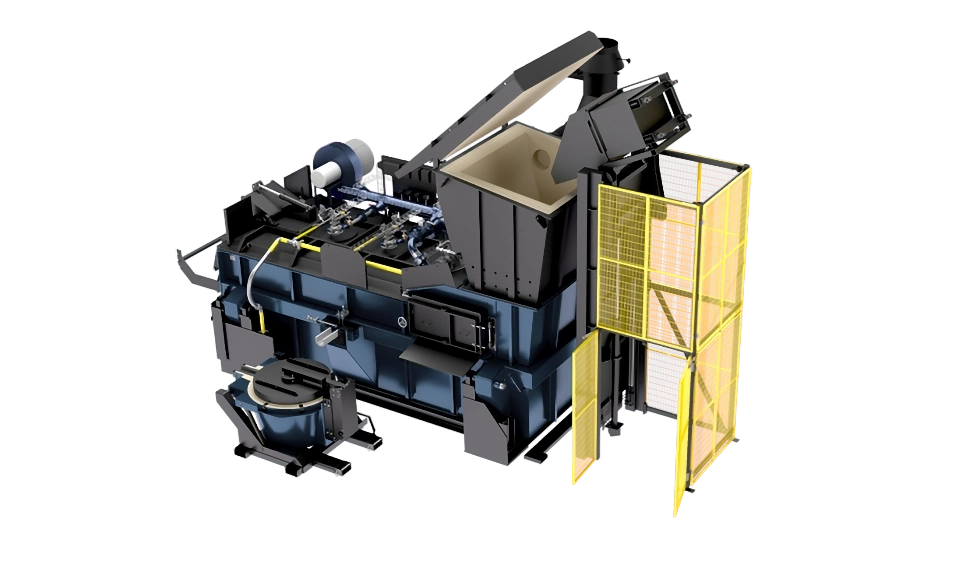

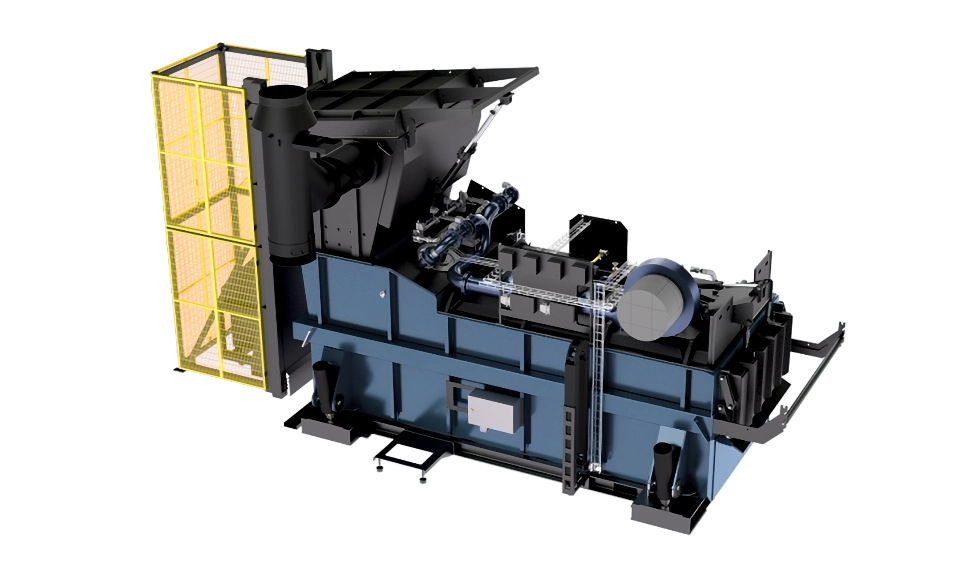

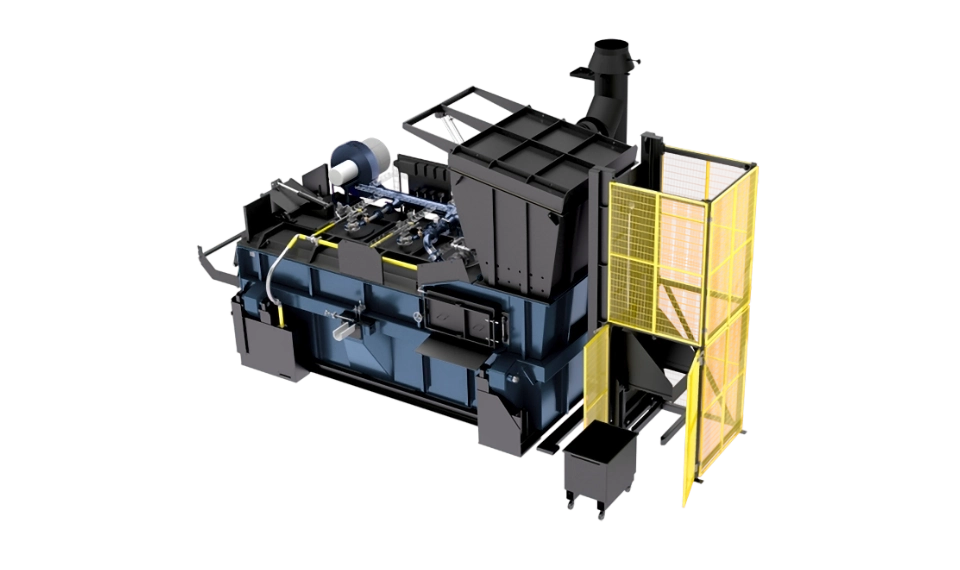

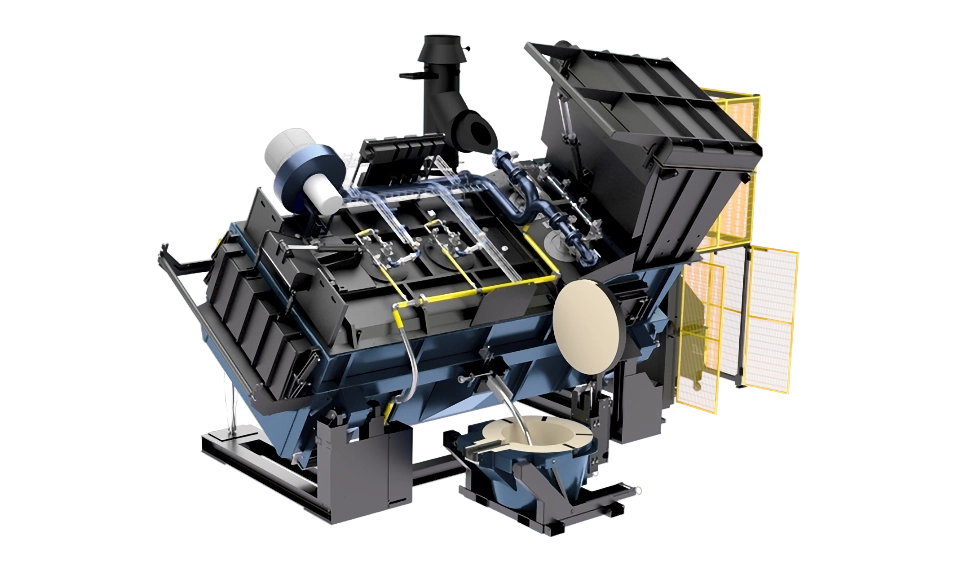

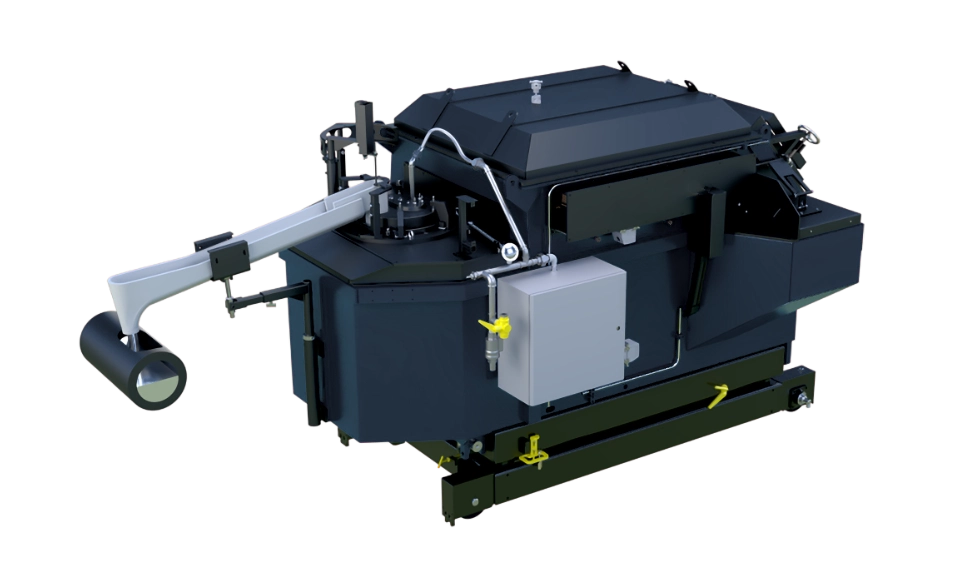

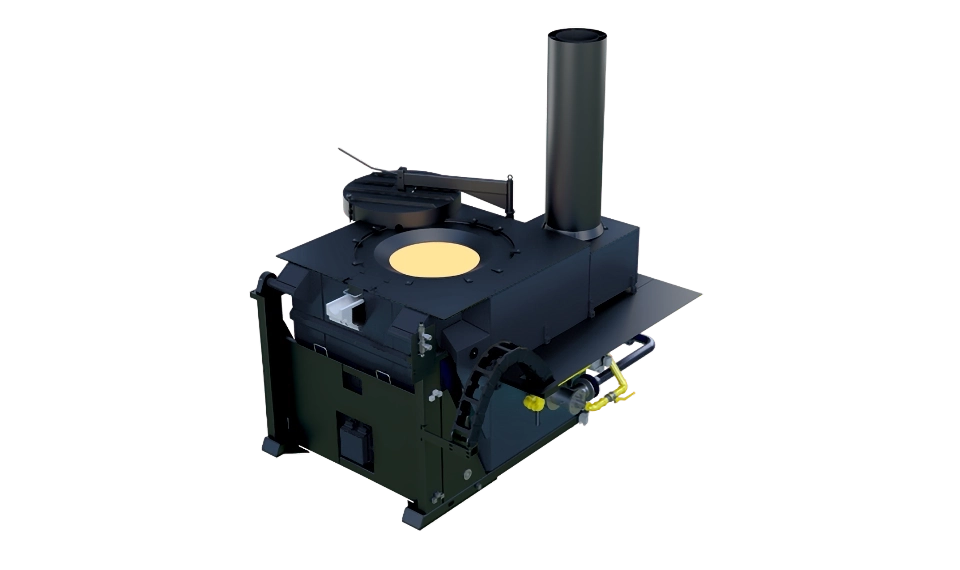

The SGT Series shaft furnaces are fully automatic, two-chamber systems designed for efficient melting and holding of aluminum. These furnaces offer melting capacities from 500 kg/h to 3,000 kg/h and holding capacities ranging from 1,500 kg to 12,000 kg of liquid aluminum. Built with a rugged steel chassis and lined with premium refractory materials, they ensure long service life and reliable thermal performance.

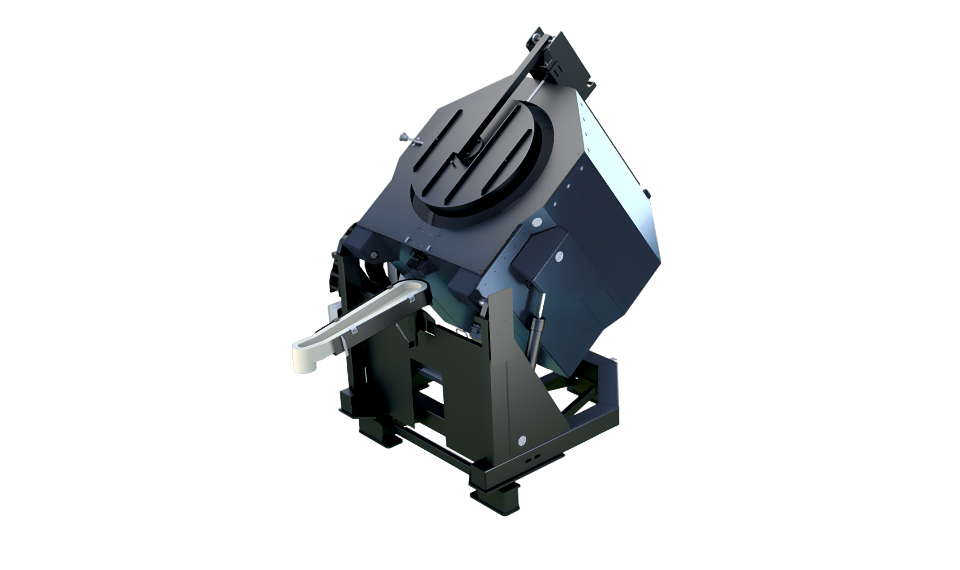

The hydraulic tilting system allows for safe and easy metal discharge, while a flat flame burner in the holding section minimizes direct flame contact, reducing metal oxidation and improving final product quality. Separate burner systems for melting and holding optimize energy efficiency and process control. A fully automated charging system supports continuous operation and consistent throughput.

Thanks to their ergonomic design, low energy consumption, and minimal maintenance requirements, SGT shaft furnaces are ideal for aluminum casting operations seeking precision, durability, and automation.

Key Characteristics

• Holding capacity: 1,500 kg – 12,000 kg

• Melting capacity: 500 kg/h – 3,000 kg/h

• High metal quality with minimized oxidation losses

• Hydraulic tilting for safe metal collection

• Automatic charging system

• Accurate temperature control in the holding chamber

• Ergonomic design for easy maintenance

• Low energy consumption

• Flat flame burner to prevent direct flame contact

• Minimal maintenance cost

• Optional versions with tap cone or dip wells and dosing pump