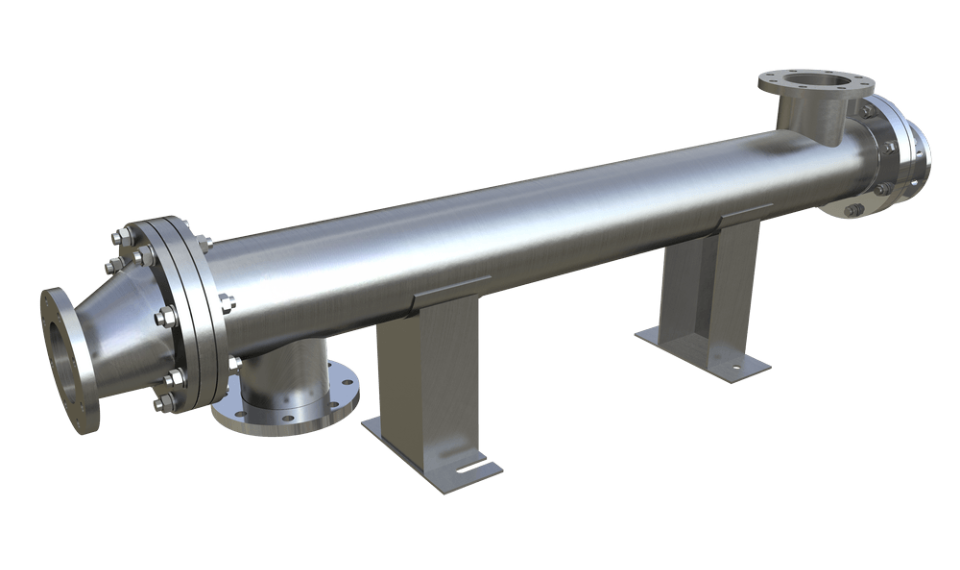

TMX Series – Spec Shell & Tube Heat Exchanger

TMX Series – Spec Shell & Tube Heat Exchanger

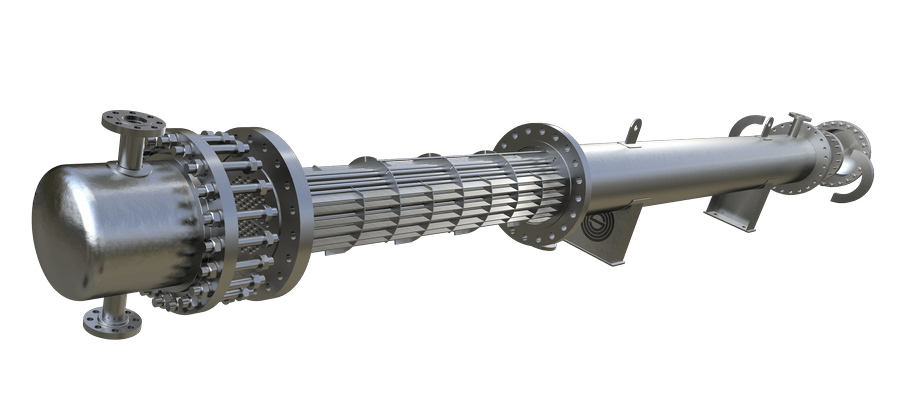

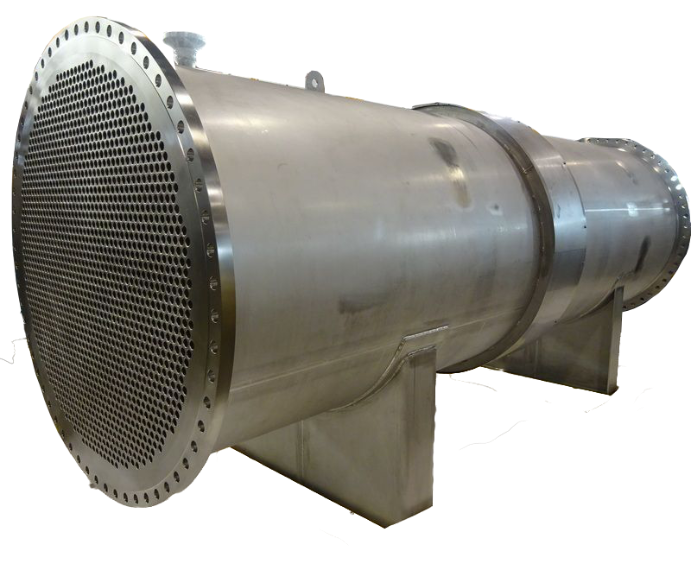

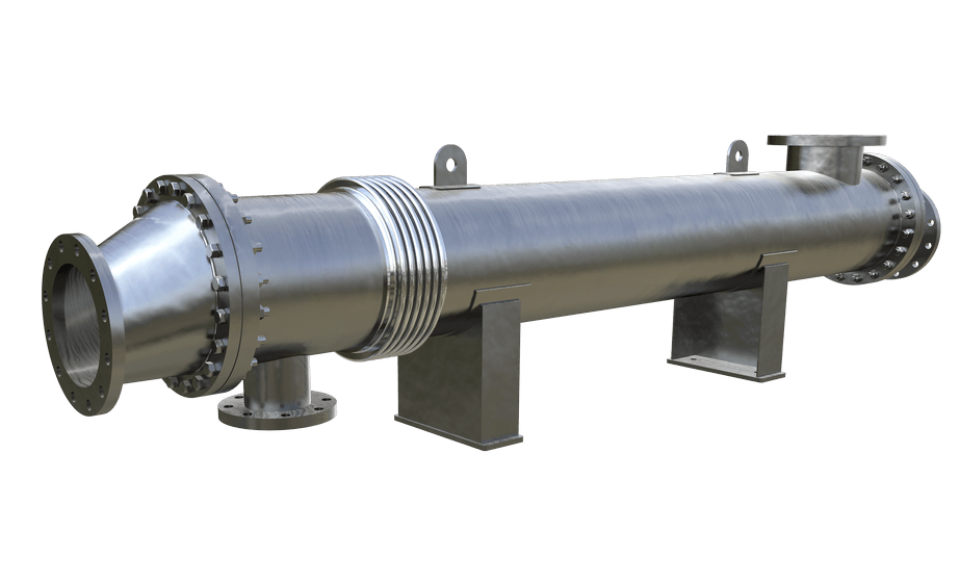

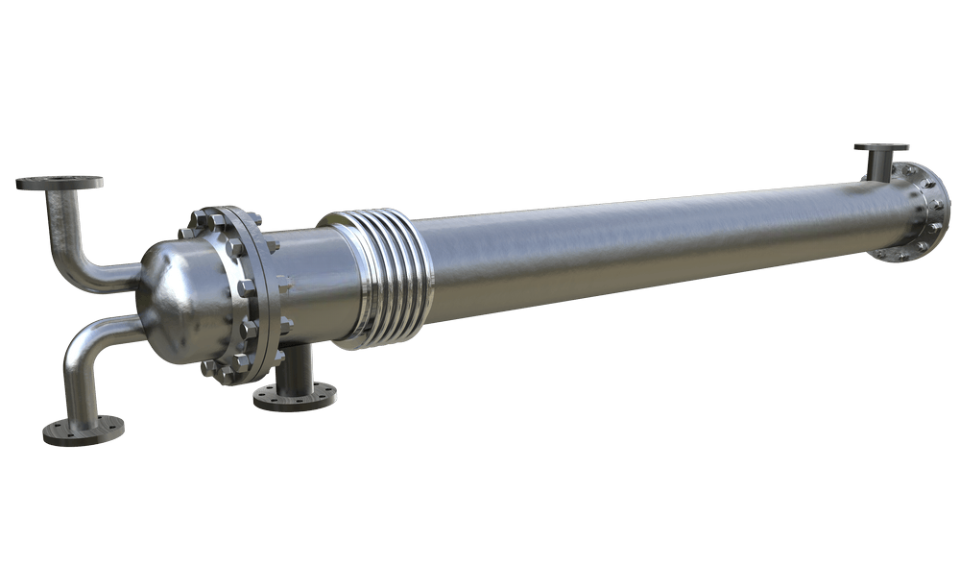

TMX Series heat exchangers are engineered in full compliance with TEMA, ASME, and PED codes, designed for demanding thermal applications across energy, chemical, oil & gas, and power industries. Available in all TEMA configurations (AEL, BEM, AES, etc.), they support high-pressure and high-temperature duties with rugged construction in carbon steel, stainless steel, or exotic alloys. Optimized for process fluid heating, cooling, or waste heat recovery, the TMX Series combines thermal efficiency, modularity, and mechanical integrity. Optional features include expansion joints, removable tube bundles, and multi-pass designs for enhanced heat transfer.

Specifications:

Standards: TEMA / ASME VIII Div.1 / PED

Configurations: All TEMA types (AEL, AES, BEU, etc.)

Tube side pressure: Up to 100 bar

Shell side pressure: Up to 50 bar

Operating temperature: −40 °C to +400 °C

Materials: Carbon steel, AISI 304/316, Hastelloy, etc.

Tube bundle: Fixed, U-tube, or floating head

Applications: Process fluids, steam, thermal oil, refrigerants

Design tools: HTRI, ASPEN, in-house CFD validation

Inspection: RT, UT, PT, hydrotest