VDF-D Series Vacuum Drum Filters

VDF-D Series Vacuum Drum Filters

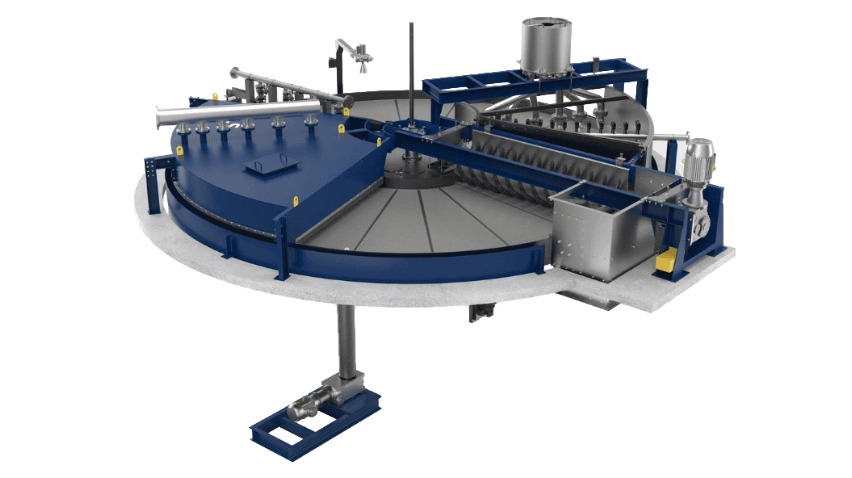

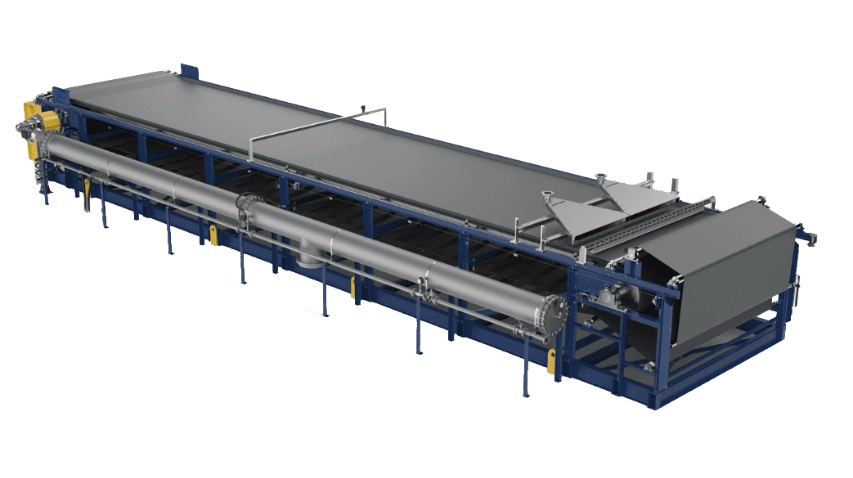

The VDF-D Series from Minerza offers versatile and efficient vacuum drum filtration for a wide range of slurry applications. With continuous operation and modular design, these filters perform all stages — cake formation, washing, drying, and discharge — during a single drum revolution. Each segment of the drum surface connects to a vacuum system that draws liquid through the filter media, capturing solids and forming a cake.

Cake thickness, drying time, and wash efficiency are fully adjustable through drum speed and valve settings, allowing precise process control. A feed agitator in the vat prevents solids from settling, ensuring consistent performance and uniform cake quality. Cake removal is performed on the descending side of the drum via mechanical or air-assisted discharge.

Designed for low maintenance and high throughput, VDF-D filters are well-suited for applications in tailings, concentrates, and chemical slurries. They also achieve excellent filtrate clarity, removing solids as fine as 100 PPM. Thanks to their low operational costs and high reliability, these filters are a smart choice for operations requiring stable, continuous dewatering.

Specifications

• Filter type: Continuous rotary vacuum drum filter

• Drum speed: Adjustable for cake thickness control

• Filtrate clarity: Down to 100 PPM solids

• Cake washing: Available via wash zone with valve control

• Discharge method: Scraper, roll, or belt discharge

• Applications: Tailings, concentrate, chemicals, food-grade slurries

• Operation: Fully automated or manual control options

• Advantages: Low energy use, high uptime, minimal operator intervention