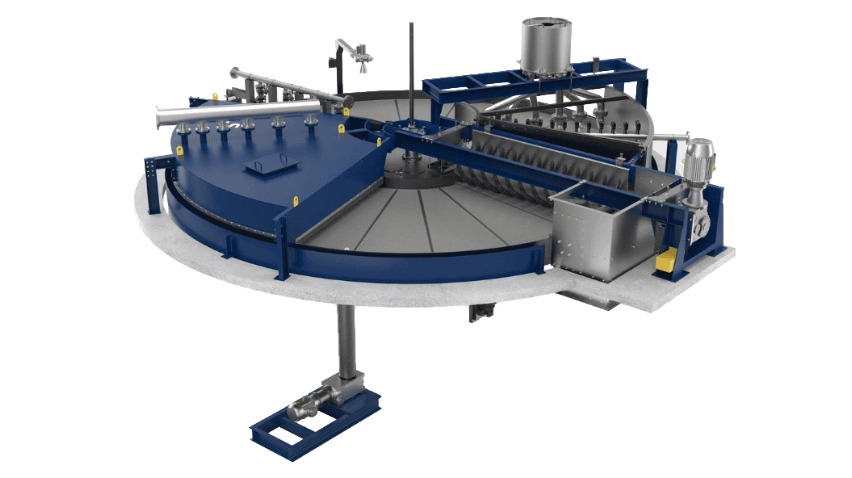

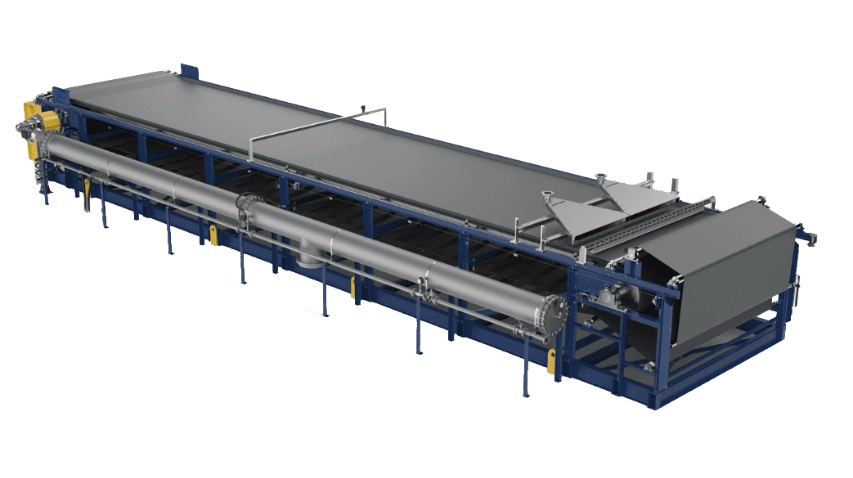

VDF Series Vacuum Disc Filters

VDF Series Vacuum Disc Filters

The VDF Series Vacuum Disc Filters from Minerza are engineered for high-capacity, continuous dewatering of rapidly settling mineral slurries. Utilizing vertical rotating discs partially submerged in slurry with automated scraping, these units efficiently form and discharge filter cake with low residual moisture. Designed for simplicity and reliability, the VDF Series delivers steady throughput, reduced maintenance, and energy-efficient operation — making them an ideal solution for tailings, concentrate and paste-fill applications.

Adaptable to a range of feed types, these disc filters operate at variable speeds (typically 30–360 rpm) with 40–52 % disc immersion depths to optimise cake formation and dewatering efficiency . Using guided scrapers and uniform filter media, the VDF Series produces clean cake discharge with minimal blinding and maintenance downtime . Advanced designs such as hyperbaric or ceramic discs further reduce moisture content and offer up to 1,500 kg/m²·h solids throughput for coarse tailings .

Specifications

• Disc rotation speed: 30–360 rpm (variable)

• Disc immersion depth: ~40–52 % of surface area

• Throughput: Up to 1,500 kg/m²·h solids (for coarse slurries)

• Final cake moisture: Typically 10–22 % depending on slurry characteristics

• Cake discharge method: Guided scrapers or blow-back cleaning

• Filter media: Cloth, synthetic fabrics, or ceramic sectors, depending on resistance requirements

• Applications: Tailings dewatering, concentrate filtration, paste backfill