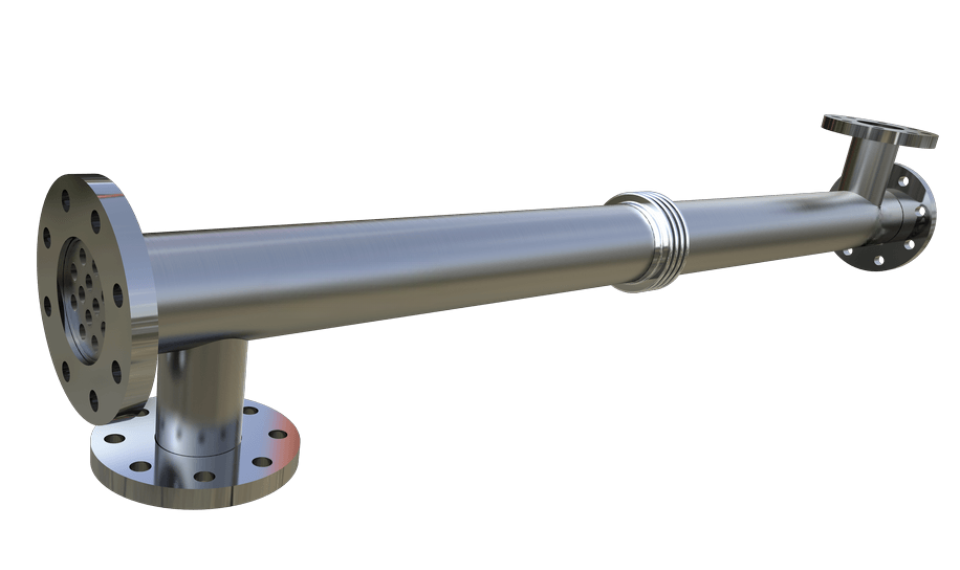

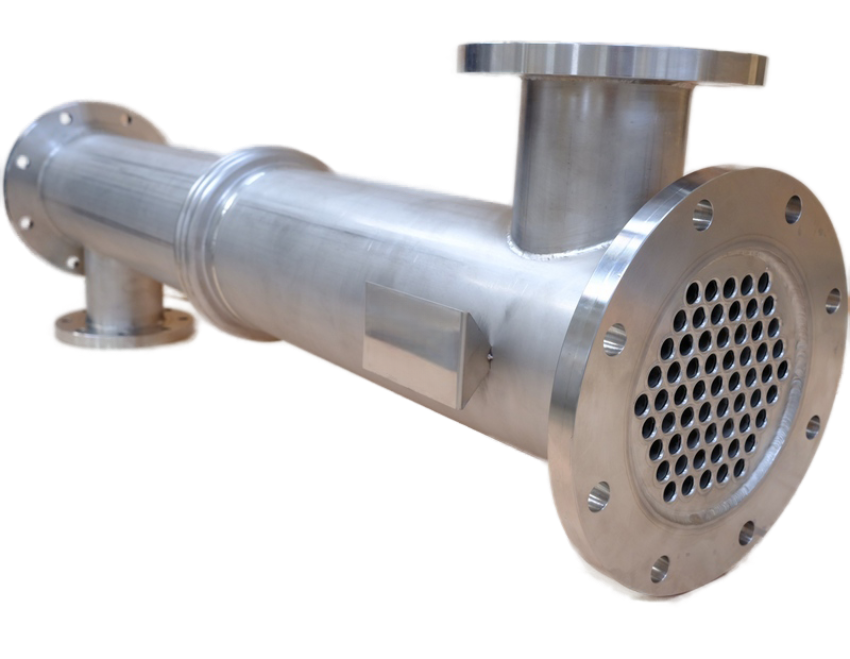

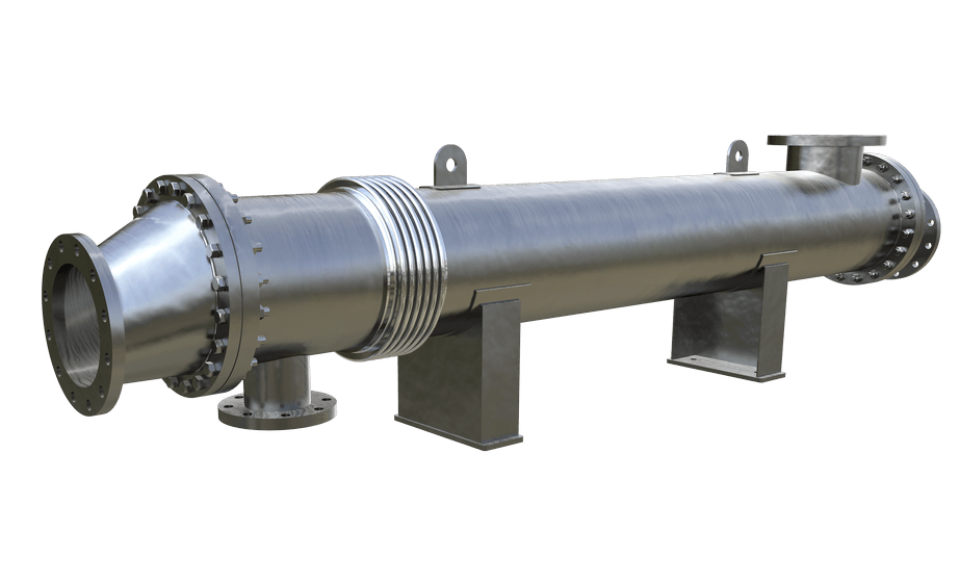

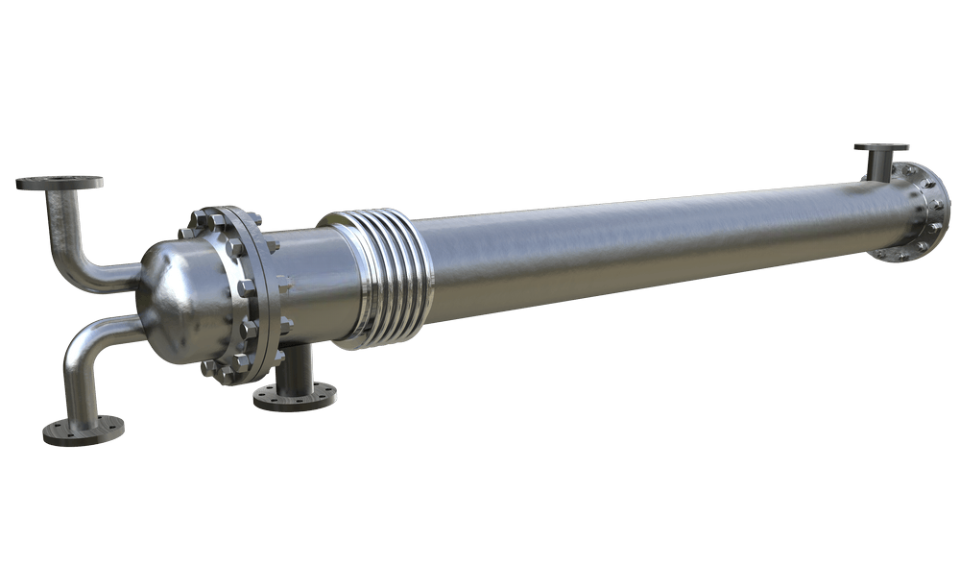

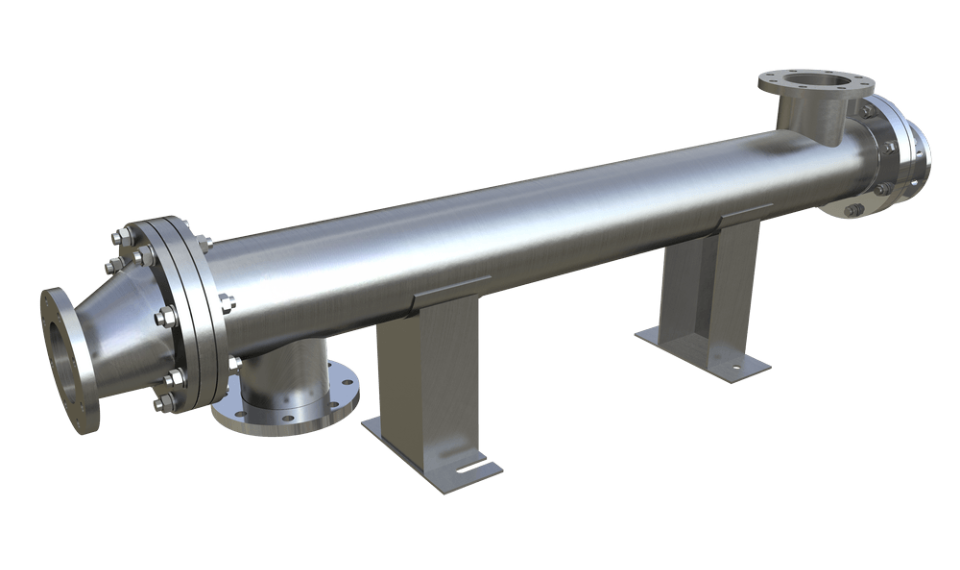

VTX Series – Smooth Tube Tubular Heat Exchanger

VTX Series – Smooth Tube Tubular Heat Exchanger

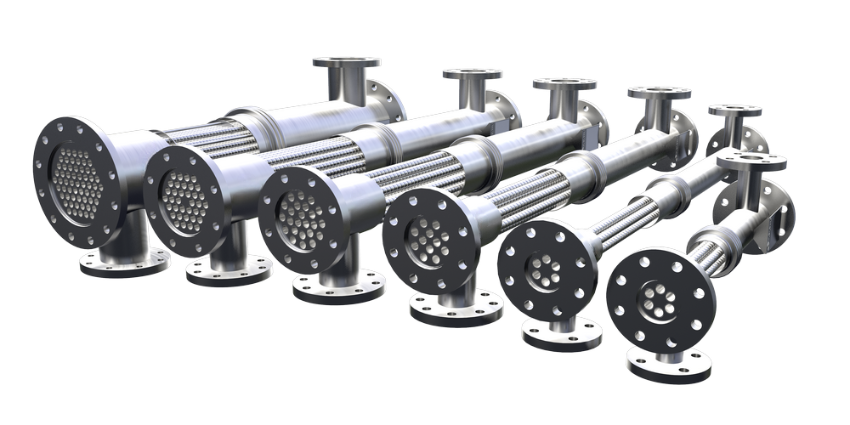

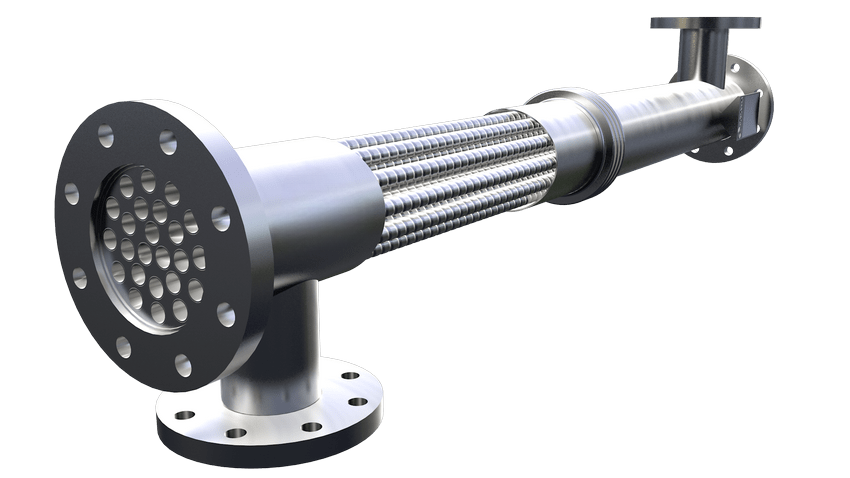

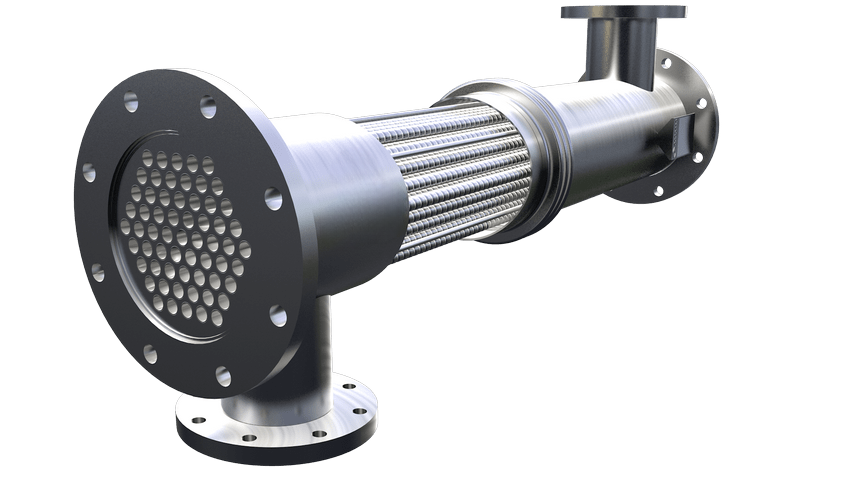

VTX Series tubular heat exchangers are designed for hygienic and sanitary applications, particularly in the food, beverage, and pharmaceutical industries. Featuring a multi-tube bundle enclosed within an outer shell, these exchangers use smooth, corrugated, or polished tubes to ensure gentle product handling and optimal heat transfer. The absence of internal baffles and the high cleanability make them suitable for CIP (Clean-In-Place) processes and viscous or particle-laden fluids. VTX units are fully compliant with FDA, 3-A, and EHEDG guidelines and can be customized for pasteurization, cooling, or heating of juices, sauces, dairy, or cosmetics.

Specifications:

Design: Multi-tube, straight or corrugated

Materials: AISI 304 / 316L stainless steel

Operating pressure: Up to 16 bar

Temperature range: −10 °C to +180 °C

Standards: 3-A / FDA / EHEDG compliant

Cleaning: CIP/SIP compatible

Applications: Food, beverage, dairy, pharma, cosmetics

Tube finish: Polished or corrugated for turbulence

Connection types: Clamp, flange, aseptic, DIN

Maintenance: Welded or fully accessible (on request)