FR Series Froth Pumps

FR Series Froth Pumps

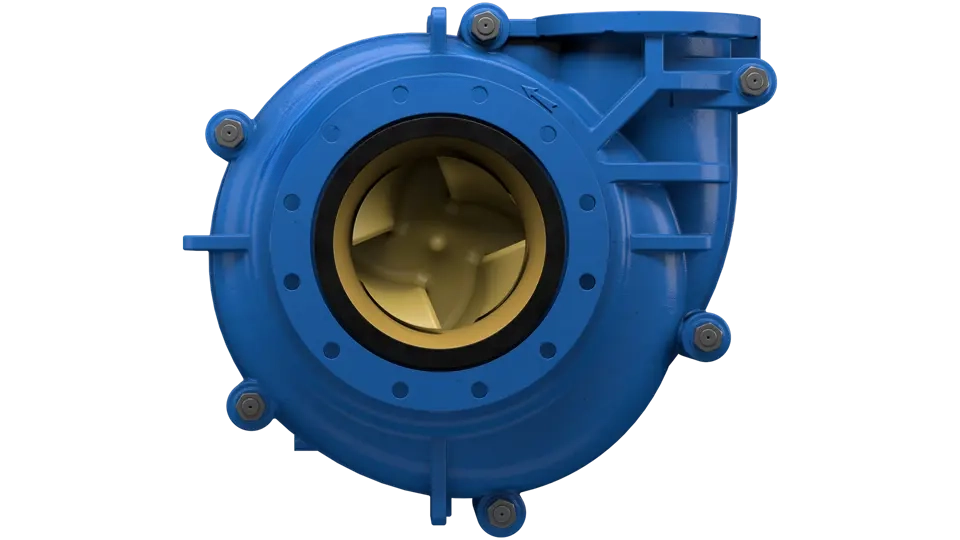

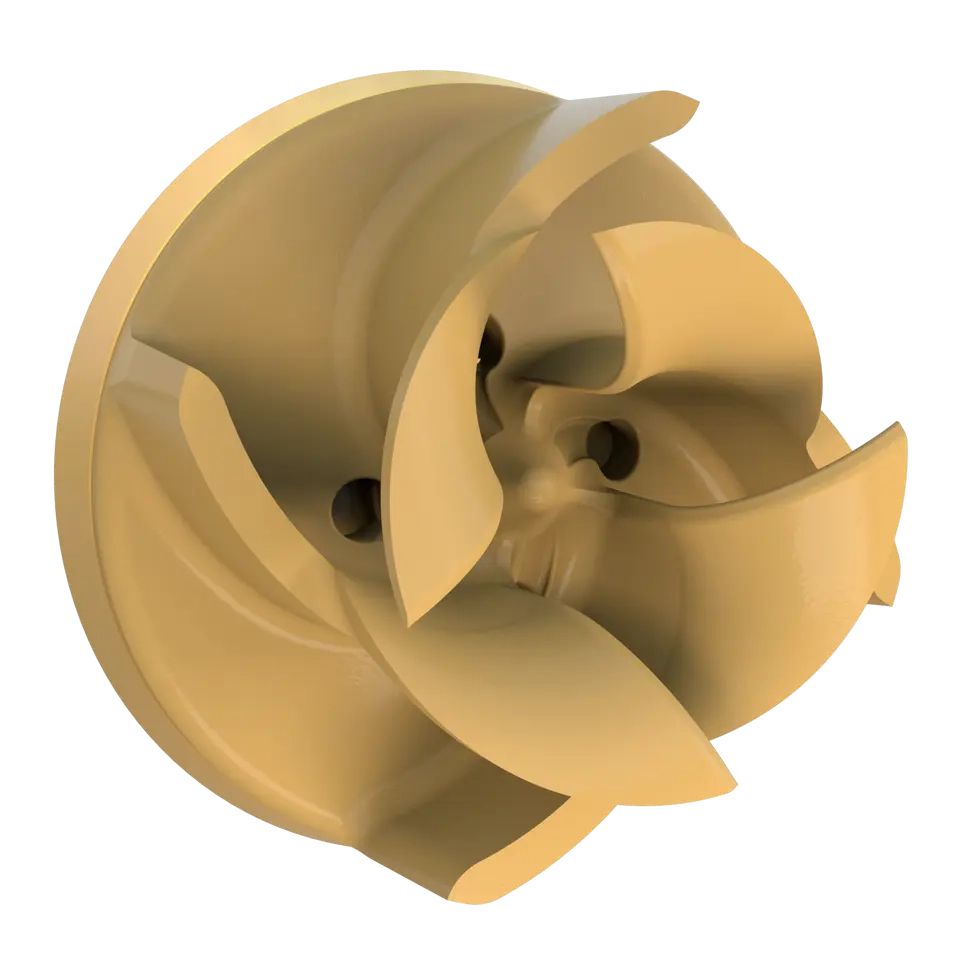

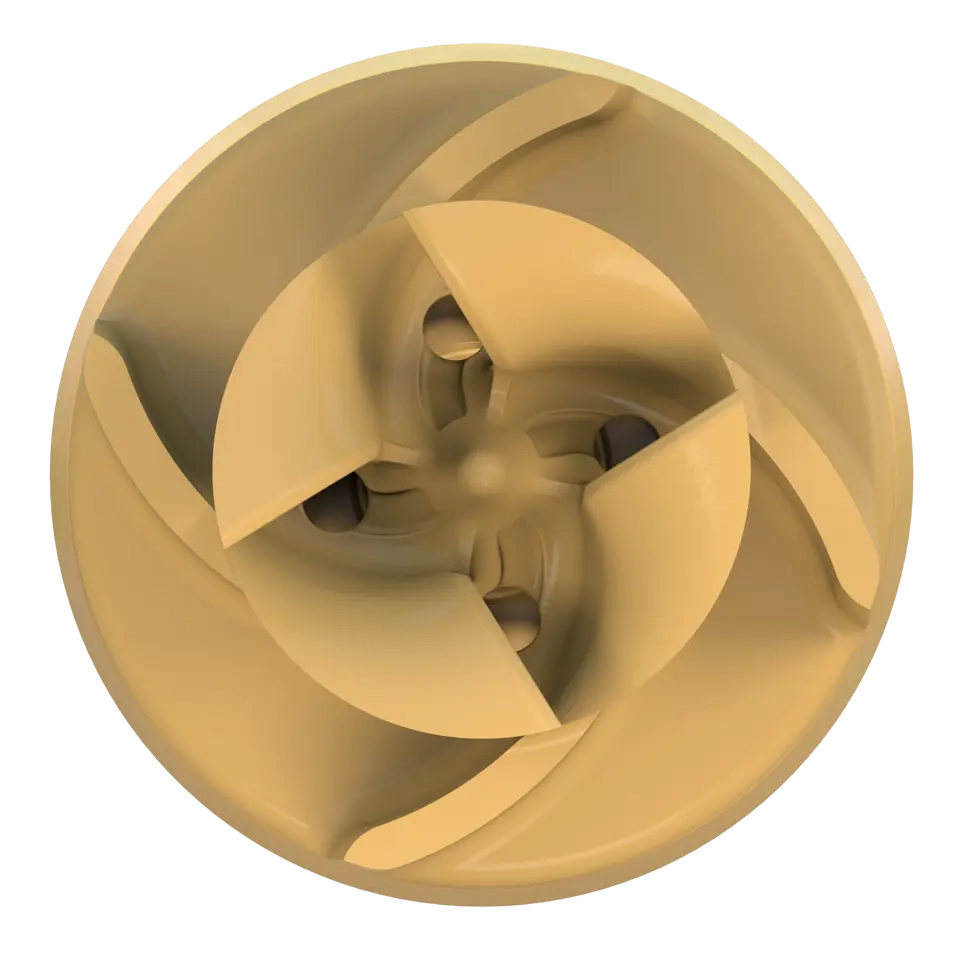

The FR Series horizontal froth pumps are purpose-built to handle air-entrained slurries, froth, and viscous, non-Newtonian mixtures common in flotation, thickening, and tailings circuits. Featuring oversized inducers and enlarged pump inlets, the FR line effectively breaks down and manages froth-laden slurries, improving overall process stability and minimizing the risk of air-locking.

Developed from the proven pump platforms, the FR Series includes three specialized models:

FRA — for high head, low flow froth applications

FRM — for medium-duty, higher flow requirements

FRL — for large-scale, high-volume installations

All models feature robust elastomer or liners and are available with the patented Continuous Air Removal System, which separates and eliminates air at the impeller eye to ensure consistent flow performance even with high froth volume factors. With cartridge-style bearing assemblies, simplified maintenance, and compatibility with existing pump footprints, the FR Series offers extended wear life, higher uptime, and excellent efficiency in demanding mineral environments.

-

Application range: Froth, paste, and viscous slurry handling

-

Design focus: Aerated slurries with fine particles

-

Models: FRA (high head, low flow), FRM (medium flow), FRL (high volume)

-

Impeller: Oversized inducer vanes for pre-swirling flow

-

Inlet design: Enlarged to reduce NPSHr and improve suction

-

Materials: Elastomer or A05 liners, ductile iron casing

-

Discharge sizes: FRA: 50–350 mm; FRM: 200–250 mm; FRL: 300–550 mm

-

Max flow capacity: Up to 8,000 m³/h depending on model

-

Seal and bearing system: Cartridge-style for safety and reliability