HRX Series Process Pumps

HRX Series Process Pumps

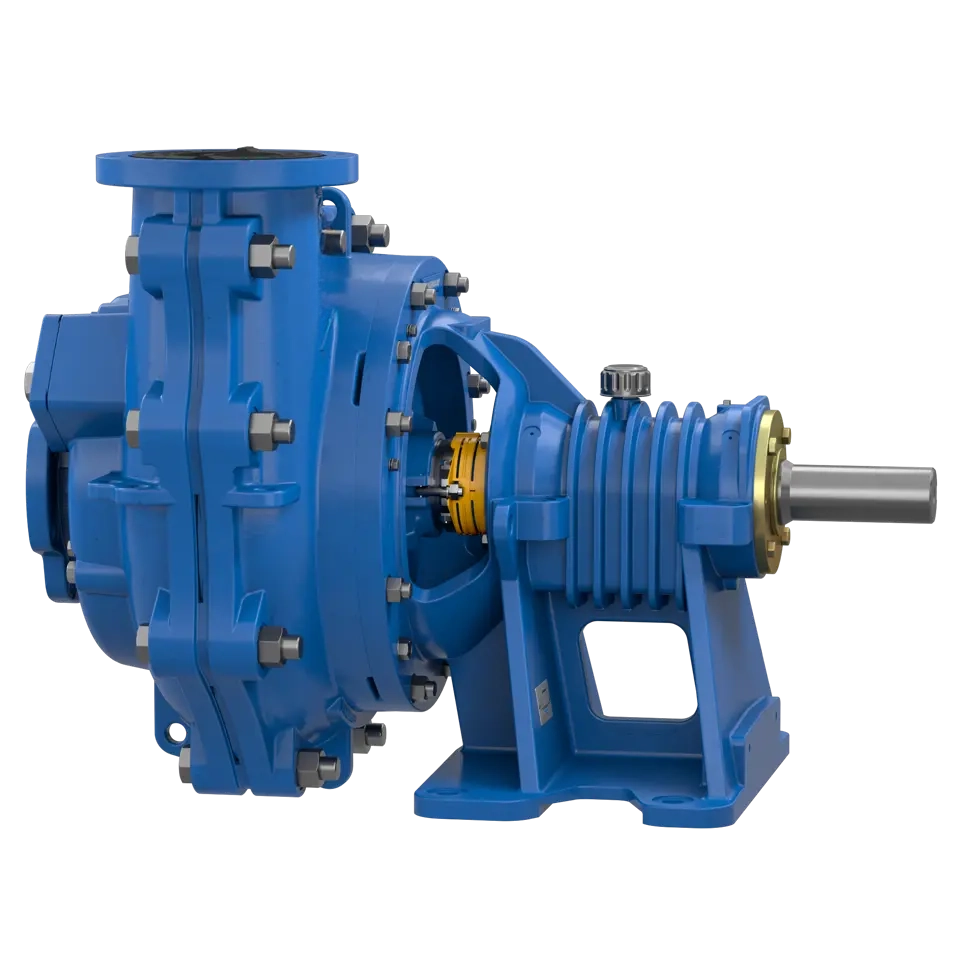

The HRX Series pumps are next-generation heavy-duty slurry pumps built for extreme abrasion resistance, extended service life, and maximum efficiency in high-demand process applications. Designed for continuous operation in mill discharge, slurry transfer, and general process pumping, the HRX Series features our patented Wear Reduction Technology, including a streamlined impeller and adjustable throatbush that ensures uniform wear and reduced energy consumption.

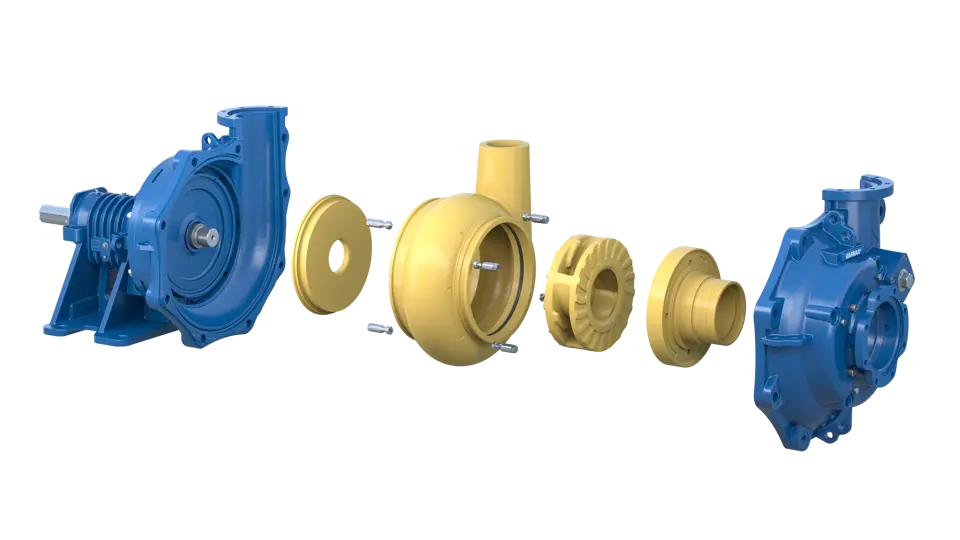

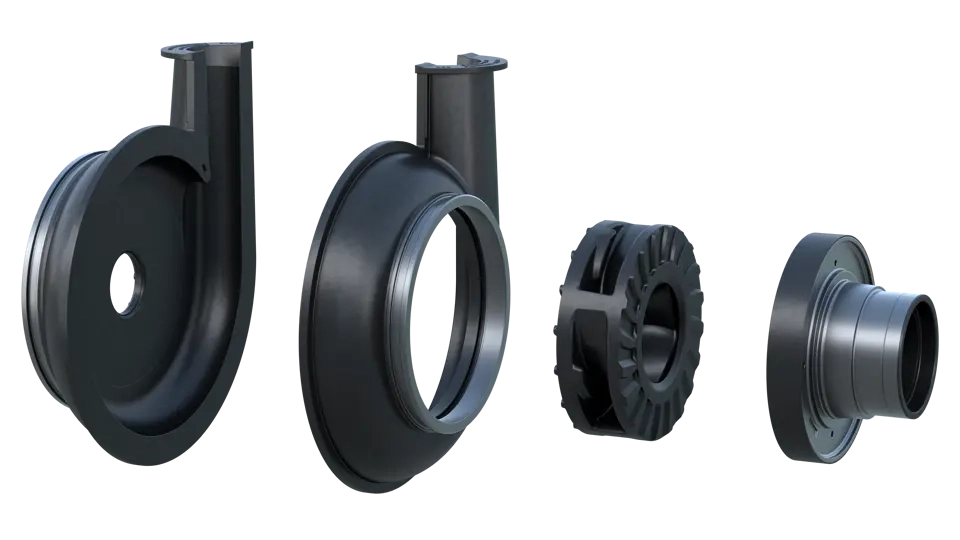

Each HRX pump is available with interchangeable elastomer or metal liners and features a revolutionary single-piece frame for precision shaft alignment and improved bearing protection. Maintenance is simplified through tool-free access to impeller and liners, integrated lifting points, and a twist-lock liner fixing system. For operations focused on safety and sustainability, the HRX Series offers reduced water usage, lower CO₂ emissions, and compatibility with automatic lubrication and monitoring systems.

Whether installed in greenfield or brownfield plants, HRX pumps provide exceptional wear life, improved hydraulic performance, and a significantly lower total cost of ownership — making them the ideal solution for Service Class 1 to 4 slurry applications.

Key Specifications:

-

Application range: Mill discharge, slurry transfer, process pumping

-

Impeller options: Metal or elastomer

-

Liners: Interchangeable elastomer or metal

-

Seal options: Expeller, mechanical, low-flow gland

-

Throatbush: Fully adjustable (axial + rotation)

-

Lubrication: Grease or oil

-

Discharge sizes: 50 mm to 450 mm

-

Frame design: One-piece bearing frame, twist-lock liners

-

Safety: Three-point lifting system, health monitoring options

-

Efficiency: Reduced power consumption and gland water use

-

Sustainability: CO₂ reduction through energy-saving impeller design