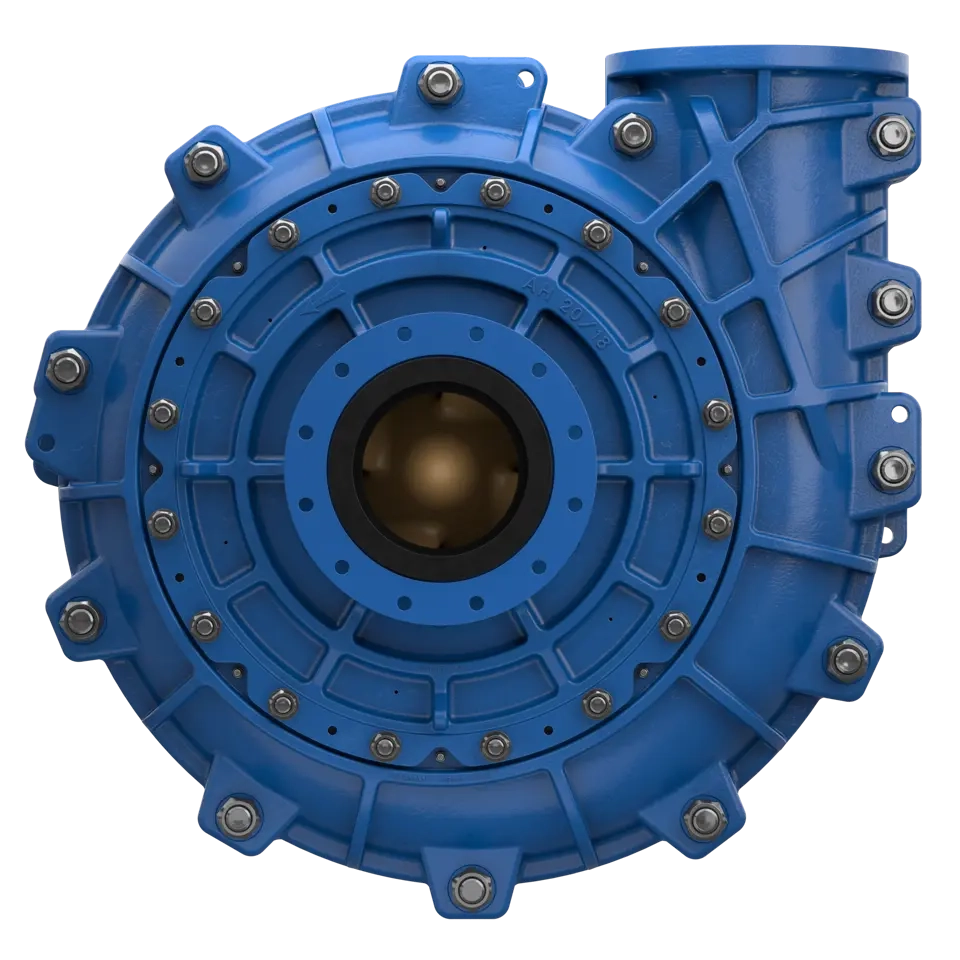

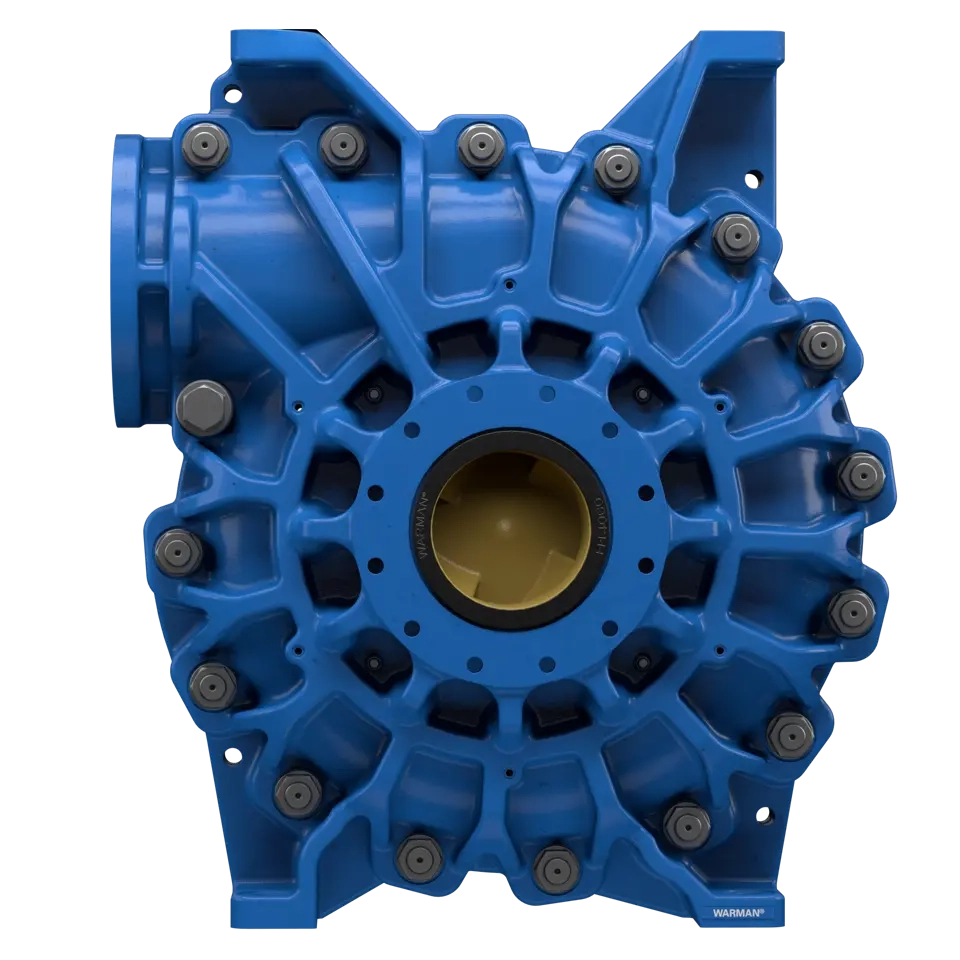

HRP Series High-Pressure Slurry Pumps

HRP Series High-Pressure Slurry Pumps

HRP Series horizontal slurry pumps are built for continuous, high-efficiency transport of highly abrasive and dense slurries in the most demanding mineral processing environments. Designed for hydrocyclone feed, flotation, tailings, regrind circuits, and other aggressive applications, they provide superior performance, extended wear life, and reduced total cost of ownership.

HRP pumps are available in standard and high-pressure configurations to accommodate a wide range of system requirements. The standard model delivers excellent efficiency and wear resistance across the entire wear cycle, while the high-pressure HRP-HP variant supports series installations and operating pressures up to 6900 kPa — making it ideal for long-distance slurry transport or tailings systems requiring multiple pumping stages.

Both models feature ductile iron outer casings and replaceable wear components made from high-chrome white iron or elastomer, depending on application needs. Optional upgrades like the WRT® impeller and throatbush improve hydraulic efficiency and extend service intervals by reducing internal turbulence and energy loss.

Specifications

-

Casing material: Ductile iron

-

Wet-end options: High-chrome white iron or elastomer liners

-

Impeller: High-chrome white iron (WRT® optional)

-

Pressure rating: Up to 6900 kPa (HRP-HP)

-

Discharge sizes: 25 mm to 450 mm

-

Applications: Cyclone feed, tailings, flotation, regrind, series pumping