EQUIPMENT

Kilns

Minerza supplies a comprehensive range of industrial kilns engineered for high-efficiency thermal processing across cement, metallurgy, and chemical sectors. Our portfolio includes gear-driven rotary kilns, indirectly heated rotary kilns, and high-temperature shaft kilns, each designed to meet specific process requirements and energy performance standards.

Rotary kilns offer continuous, high-throughput operation with excellent temperature control, suitable for calcination, sintering, and pyrolysis. Gear-driven models ensure smooth rotation and long-term mechanical stability, even in harsh conditions. For processes requiring indirect heating—such as materials sensitive to combustion gases—our indirectly heated kilns deliver precise thermal transfer without direct flame contact.

Shaft kilns provide a compact and fuel-efficient alternative for vertical calcination, commonly used in lime and dolomite production. Their counter-current operation maximizes heat recovery and reduces emissions, making them ideal for applications where space, energy efficiency, and environmental compliance are critical.

Whether your operation demands high-capacity rotary systems or compact shaft configurations, Minerza kilns are built to deliver consistent product quality, reduced fuel consumption, and seamless integration into complex process lines.

KILN

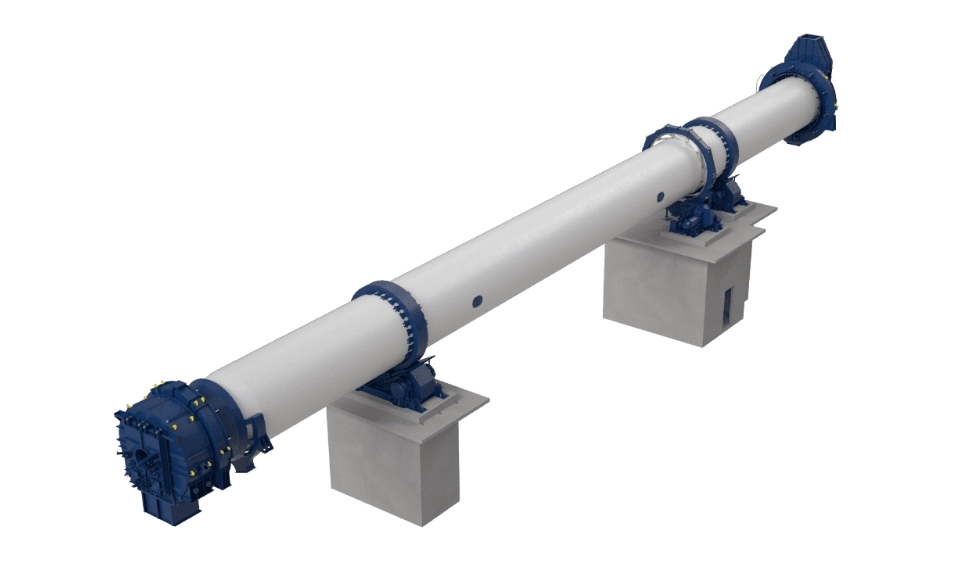

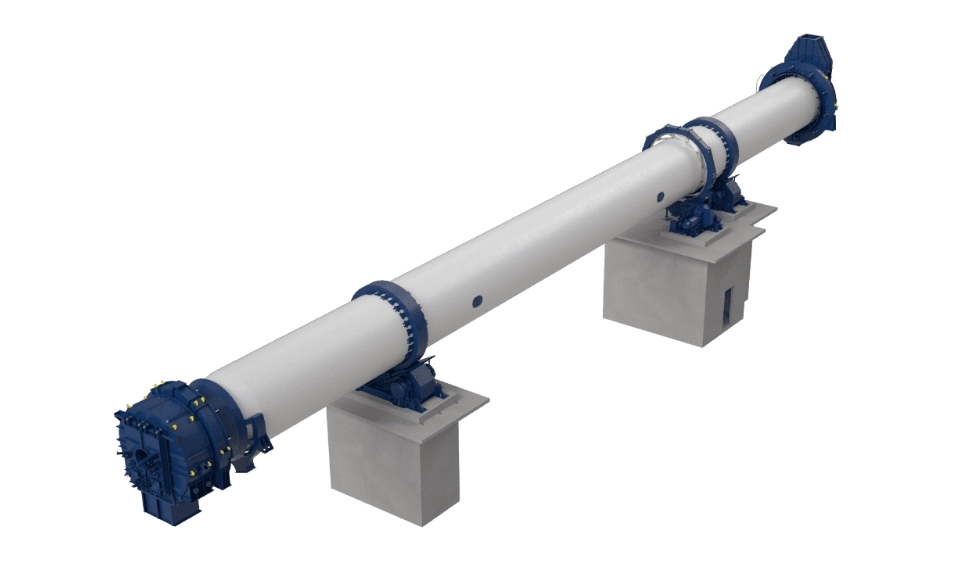

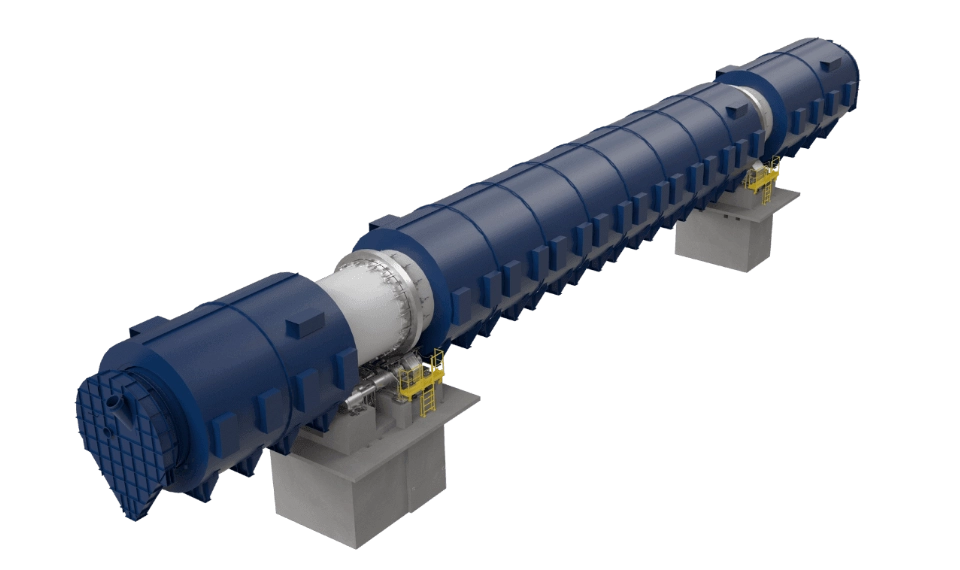

KRN Series – Gear-Drive Rotary Kiln

Versatile gear-driven rotary kilns engineered for high-capacity thermal processing of cement, lime, and industrial minerals with advanced efficiency and process control.

KILN

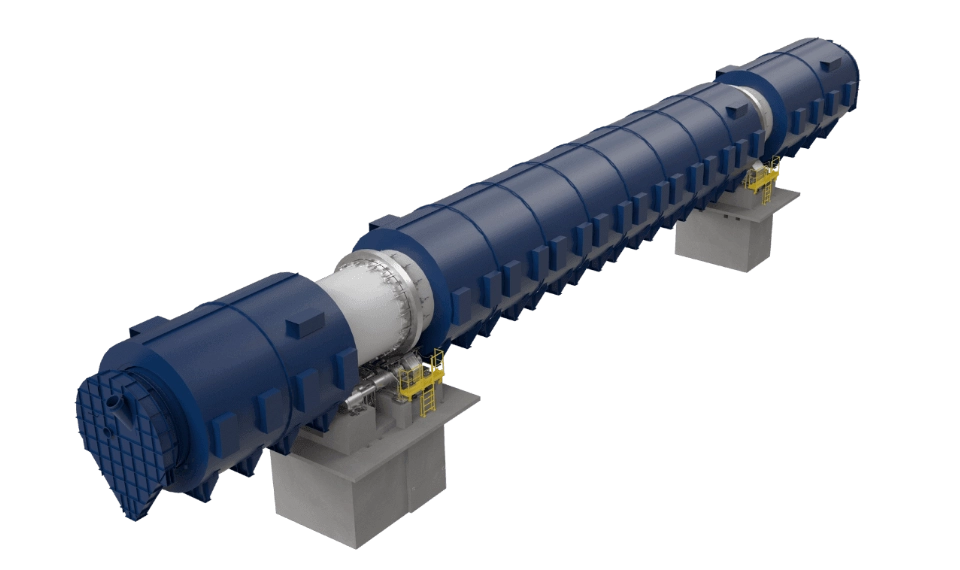

KRI Series – Indirectly-Heated Rotary Kiln

Indirectly-heated rotary kilns engineered for precise thermal processing of sensitive or hazardous materials in inert or sealed environments.

KILN

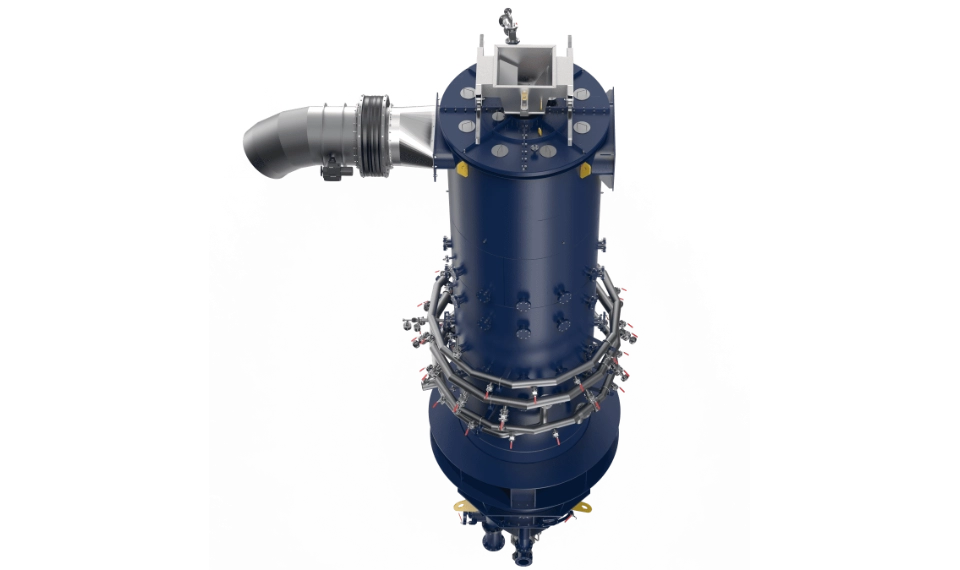

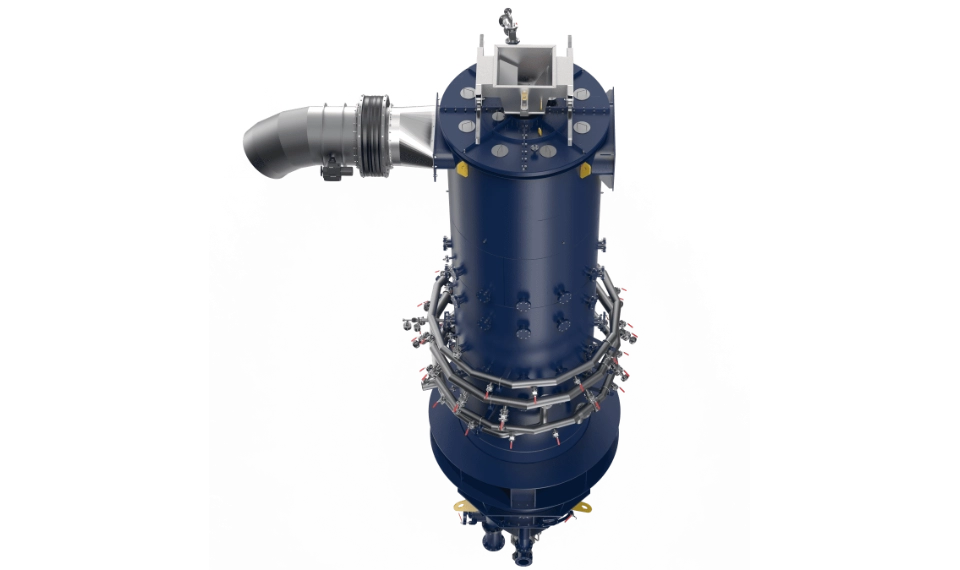

KSH Series – High-Temperature Shaft Kiln

Vertical shaft kilns designed for high-temperature calcination with superior thermal efficiency, ideal for continuous lime and refractory material production.

KILN

KRN Series – Gear-Drive Rotary Kiln

Versatile gear-driven rotary kilns engineered for high-capacity thermal processing of cement, lime, and industrial minerals with advanced efficiency and process control.

KILN

KRI Series – Indirectly-Heated Rotary Kiln

Indirectly-heated rotary kilns engineered for precise thermal processing of sensitive or hazardous materials in inert or sealed environments.

KILN

KSH Series – High-Temperature Shaft Kiln

Vertical shaft kilns designed for high-temperature calcination with superior thermal efficiency, ideal for continuous lime and refractory material production.

Furnaces

Aluminium furnaces are essential for melting, holding, and dosing operations in casting and foundry lines, particularly in automotive and high-precision industries. These systems are engineered to optimize energy efficiency, dosing accuracy, and operational safety across a variety of production needs. Whether electric or gas-fired, stationary or tilting, each furnace model is built to deliver consistent performance, high metal purity, and reduced operating costs.

We offer a full line of advanced aluminium furnace technologies, including shaft furnaces, crucible furnaces, and precision dosing systems — all supported by intelligent PLC control and optional automation features.

SMD Series – Alumelter Electric Dosing Furnace

Combines melting, holding, and precision dosing in a single, energy-efficient electric crucible furnace for aluminium casting.

SFD Series – Alumelter Gas Tilting Furnace

Gas-fired crucible furnace with hydraulic tilting for efficient aluminium melting and holding with precise temperature control and robust performance.

SDD Series – Alumelter Electric Tilting Furnace

Fully automated electric crucible furnace with hydraulic tilting, ideal for clean melting and up to 40% lower energy consumption.

STE Series – Aluminium Dosing Furnace

High-efficiency aluminium dosing furnace with ±1% dosing accuracy, low gas consumption, and up to 80% cost savings thanks to a patented pressurized ceramic unit and intelligent PLC control.

SGT Series – Aluminium Shaft Furnace

High-efficiency shaft furnace for aluminium melting and holding with low energy use, safe metal handling, and full automation.

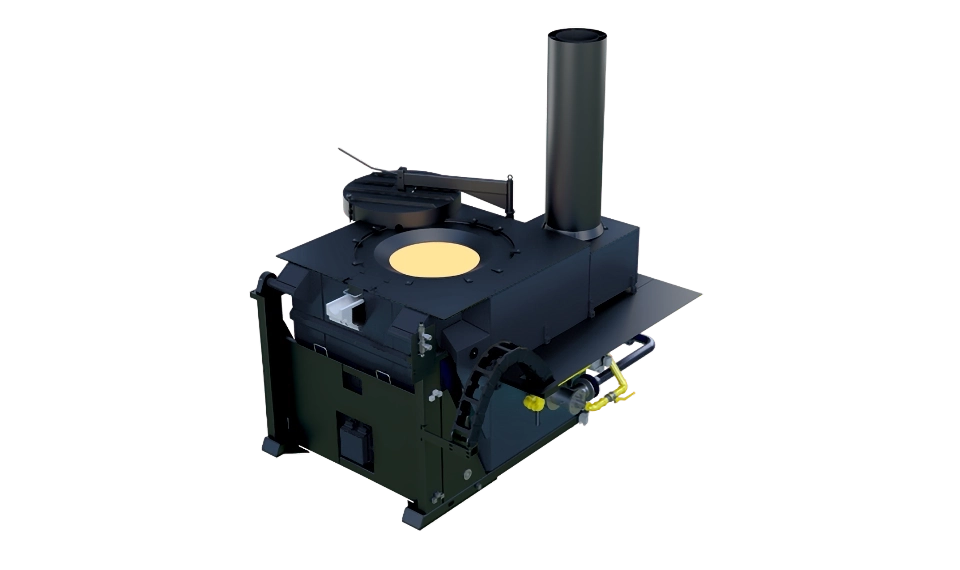

FURNACE

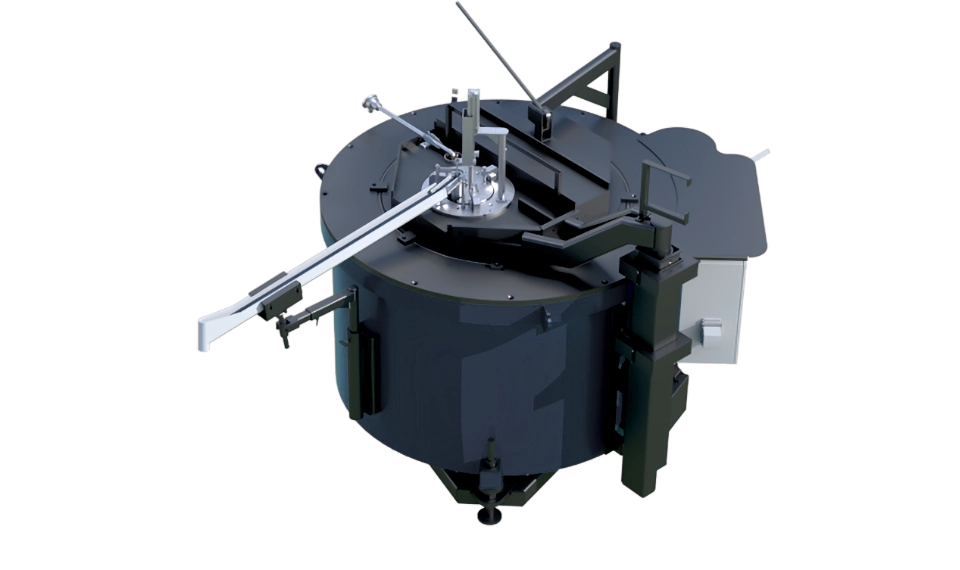

SGT Series – Aluminium Shaft Furnace

SGT Series shaft furnaces provide high-efficiency aluminum melting and holding with low energy use, safe metal handling, and full automation.

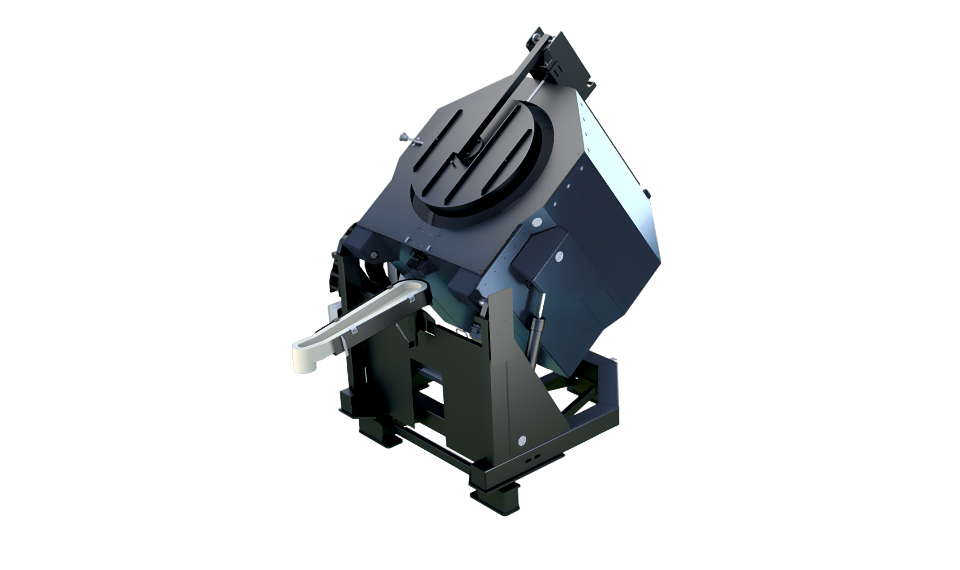

FURNACE

SMD Series – Alumelter Electric Dosing Furnace

SMD Series combines melting, holding, and precision dosing in a single, energy-efficient electric crucible furnace for aluminum casting.

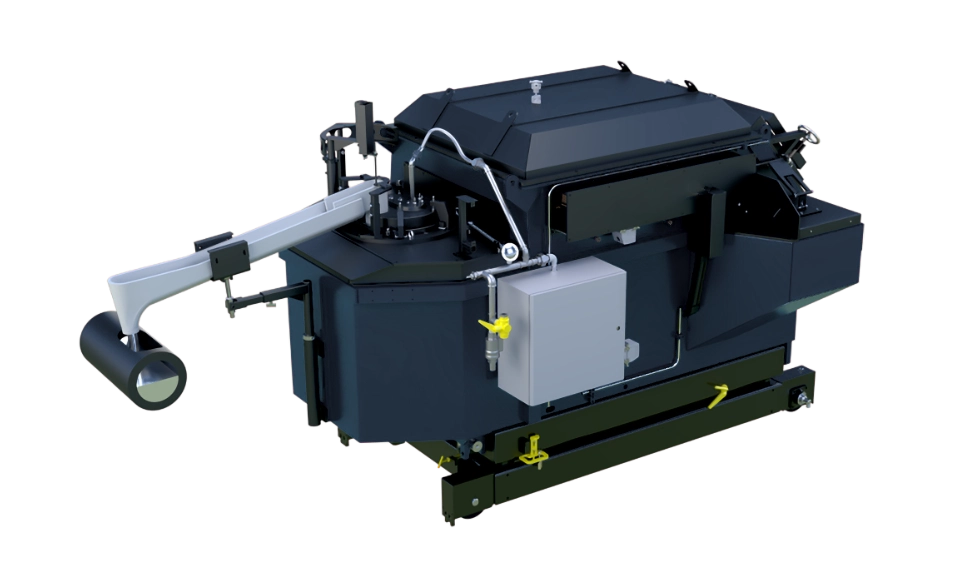

FURNACE

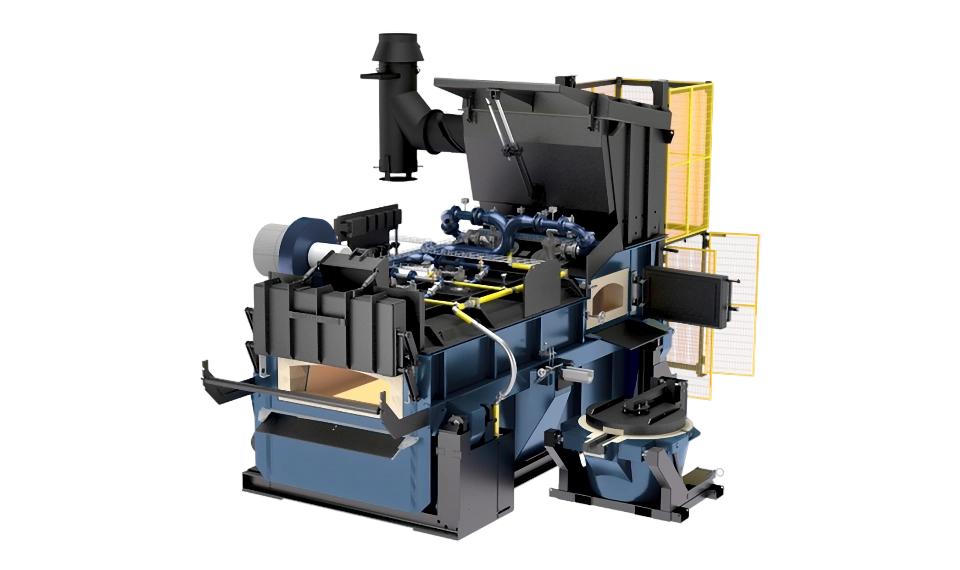

SFD Series – Alumelter Gas Tilting

SFD Series gas-fired crucible furnace with hydraulic tilting for efficient aluminum melting and holding with precise temperature control and robust performance.

FURNACE

SDD Series – Alumelter Electric Tilting

SDD Series furnaces offer fully automated aluminum melting and holding with hydraulic tilting, high durability, and up to 40% lower energy consumption.

FURNACE

STE Series – Aluminium Dosing Furnace

High-efficiency aluminium dosing furnace with ±1% dosing accuracy, low gas consumption, and up to 80% cost savings thanks to a patented pressurized ceramic unit and intelligent PLC control.