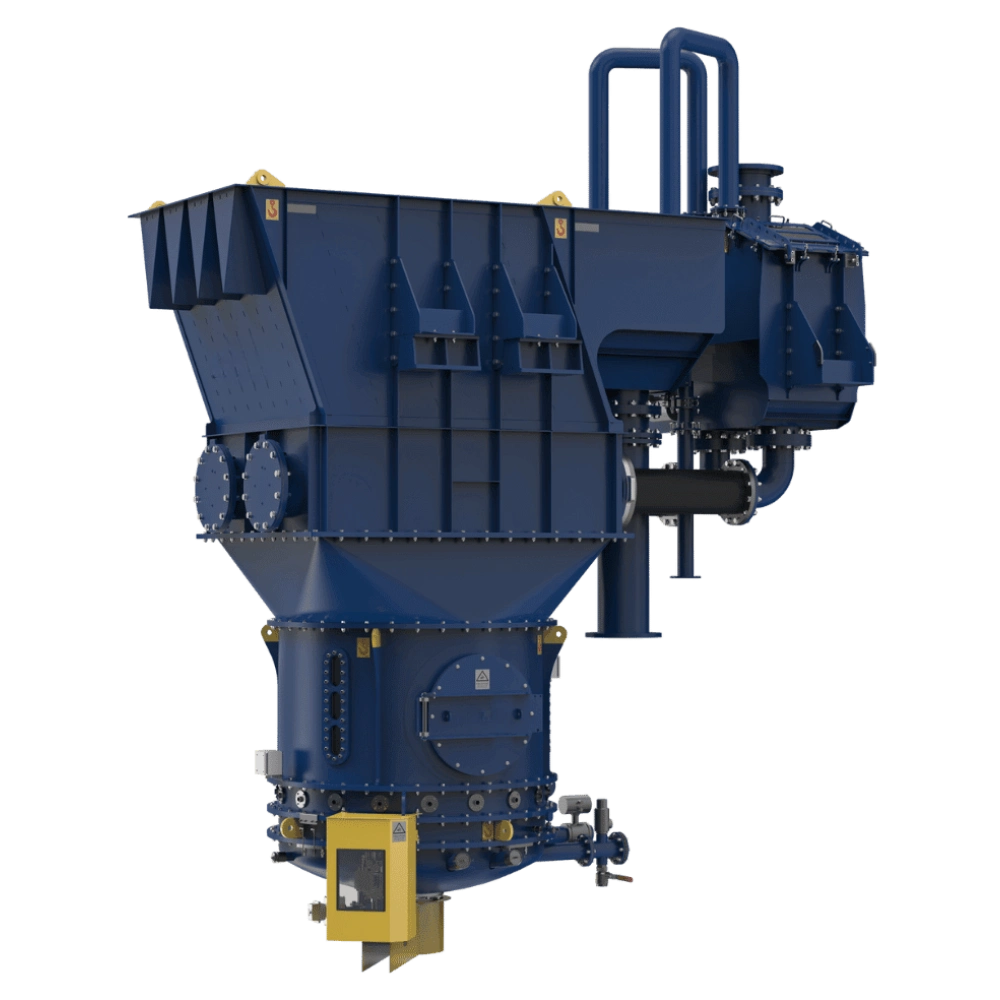

CFC Series Coarse Flotation Cells

CFC Series Coarse Flotation Cells

Our CFC Series Coarse Flotation Cells are engineered to recover coarse particles that are typically lost in traditional flotation. With advanced hydraulic design and low-energy dispersion, they allow efficient flotation of particles up to 850 μm, reducing overgrinding and lowering total energy consumption.

Each cell features a deep tank with a high aspect ratio to extend residence time and promote selective attachment of coarse particles to bubbles. A controlled flow regime, stable froth zone, and low-shear mixing system ensure high-grade recovery with minimal entrainment of fines — making the CFC Series ideal for coarse mineral applications in copper, gold, and phosphate processing.

To support circuit design and validation, modular pilot units are available for on-site testing. These plug-and-play systems require only a small stream of rougher feed and can be seamlessly integrated into existing operations. During trials, our engineering team works closely with clients to fine-tune performance and validate recovery gains under real process conditions.

-

Particle Size Range: Up to 850 μm

-

Tank Geometry: Deep tank, high aspect ratio

-

Mixing System: Low-energy hydrodynamic dispersion

-

Froth Stability: Wide, stable froth zone for coarse recovery

-

Air System: Controlled external forced-air supply

-

Applications: Copper, gold, phosphate, and other coarse mineral circuits

-

Throughput: Designed for high-capacity rougher or scavenger duties

-

Maintenance: Simple internals and easy-access wear liners

-

Pilot Trials: Modular units available for on-site testing and process validation