SYSTEMS

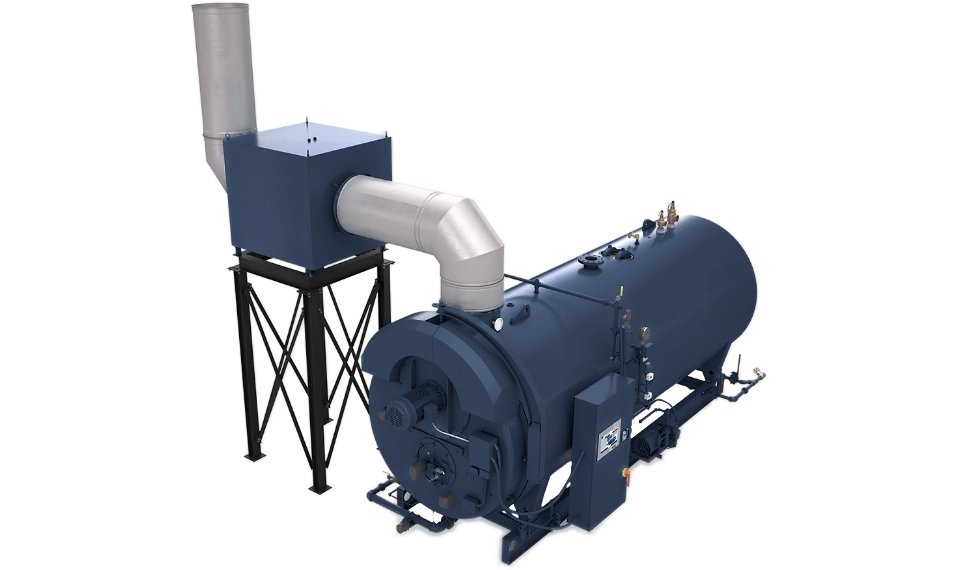

Steam Boilers

Minerza offers a comprehensive range of high-performance steam boilers engineered for industrial and commercial steam generation. Designed with a focus on efficiency, reliability, and modularity, our boilers support a wide output range — from 300 to 55 000 kg/h — and pressures up to 30 bar, covering the needs of small facilities to large-scale manufacturing plants.

The portfolio includes compact pre-assembled systems for fast installation, as well as high-capacity boilers with dual-flame tube configurations for flexible part-load operation. Thanks to Bosch’s proven three-pass flame tube design, integrated economisers, and low-NOx burner compatibility, all models ensure stable steam delivery with optimized fuel consumption.

Each system is equipped with intelligent automation via Bosch Control 8000 (BCO/SCO), enabling smart monitoring, remote access, and seamless integration into modern energy infrastructure. Compatible with natural gas, coal, light oil, biogas, or hydrogen blends, Minerza steam boilers meet current environmental and safety standards while delivering reliable long-term performance.

Whether you need plug-and-play steam for food and pharma, or high-output solutions for chemical, textile, or energy applications — our lineup is built to adapt, endure, and perform.

STEAM BOILER

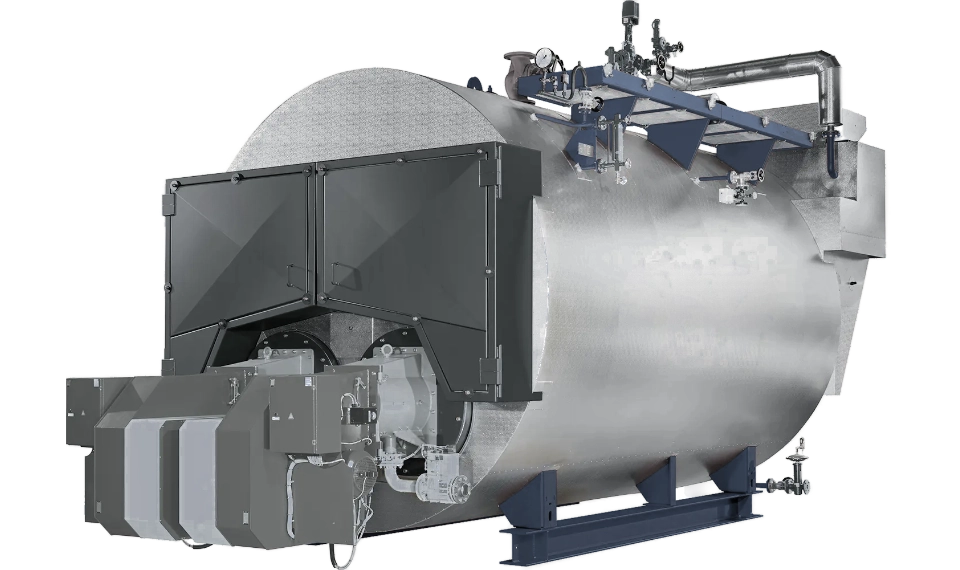

ZFX Series – High‑Capacity Steam Boiler

ZFX Series three‑pass steam boilers deliver 18 000–55 000 kg/h at up to 30 bar, with options for saturated or superheated steam to 300 °C. With dual burners, separate flue paths, economiser, and smart control, they offer high efficiency, low‑NOₓ/hybrid fuel readiness, and robust operation.

STEAM BOILER

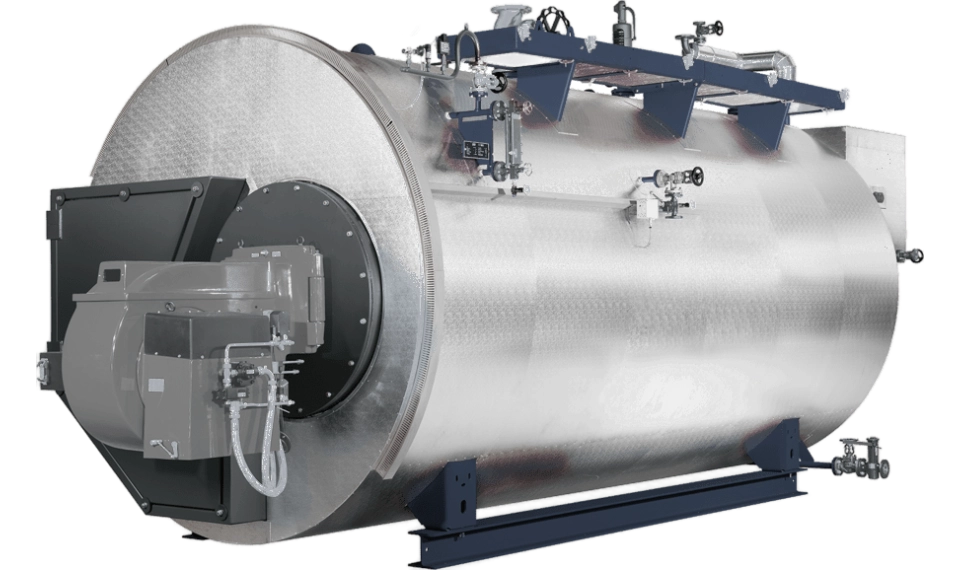

ULS Series – High-Efficiency Shell Boiler

ULS Series three-pass steam boilers offer 1 250–28 000 kg/h output at up to 30 bar. Designed for high efficiency (up to 95.5%) with optional heat recovery, support saturated or superheated steam and integration with modern control systems, enabling sustainable and flexible steam generation.

STEAM BOILER

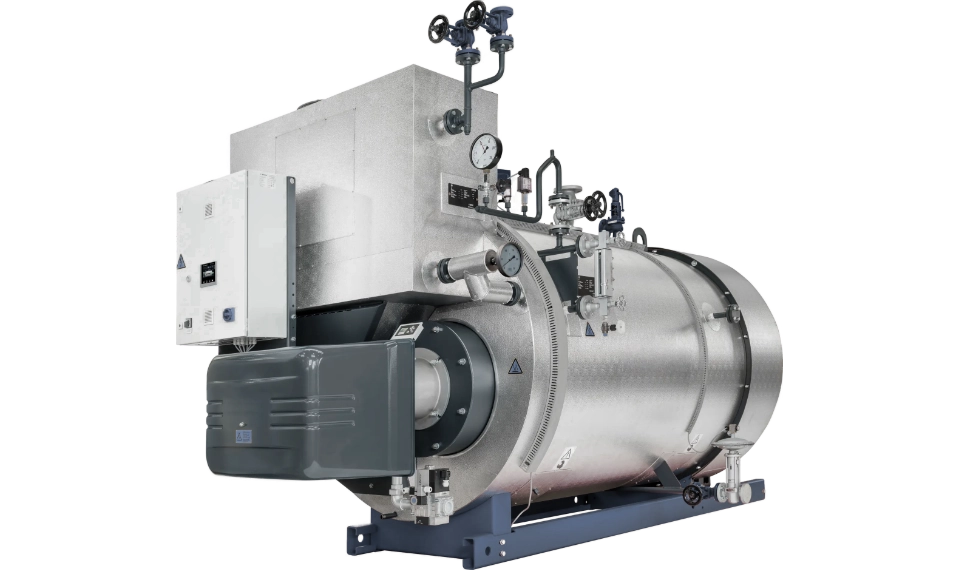

CSX Series – Compact Steam Boiler

CSX Series compact steam boilers deliver 300–5 200 kg/h at up to 16 bar, combining high efficiency (up to 95.3%) with a space-saving design. Equipped with smart controls and ready for gas, oil, or hydrogen blends, they offer fast commissioning and reliable steam for commercial and industrial use.

STEAM BOILER

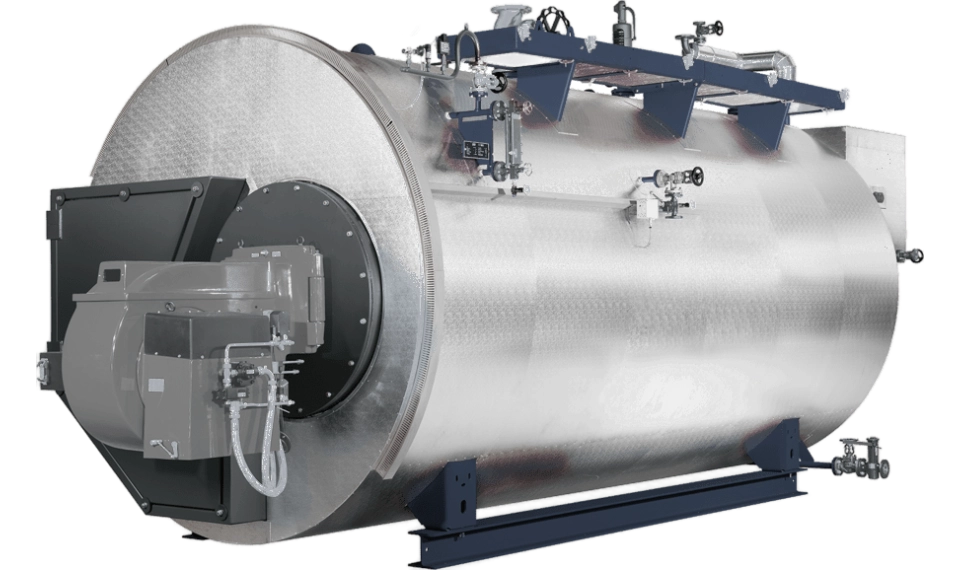

UMB Series – Modular Steam Boiler

UMB Series steam boilers deliver 200–2 000 kg/h with multi-flame tube three-pass design for stable and efficient steam generation. Compact and modular, they offer excellent part-load behavior, quick startup, making them ideal for commercial and small industrial operations.

STEAM BOILER

ULS Series – High-Efficiency Shell Boiler

ULS Series three-pass steam boilers offer 1 250–28 000 kg/h output at up to 30 bar. Designed for high efficiency (up to 95.5%) with optional heat recovery, support saturated or superheated steam and integration with modern control systems, enabling sustainable and flexible steam generation.

Economizers

We offer a complete range of industrial economizers engineered to boost boiler efficiency through effective heat recovery. Designed for both new installations and retrofits, our solutions include non-condensing and condensing types, covering steam and hot water systems across a broad range of fuel types and operating conditions.

From compact single-stage units to advanced two-stage and fully condensing systems, our economizers recover sensible and/or latent heat from flue gases, preheating feedwater, make-up water, or process fluids. This allows facilities to achieve fuel savings of up to 18%, while reducing emissions and improving thermal performance.

With vertical or horizontal gas flow options, modular or skid-mounted construction, and materials including carbon steel, stainless steel, or high-alloy components, Minerza economizers are built to adapt to your plant’s specific layout and thermal requirements. Each unit integrates seamlessly with existing boiler equipment and can be paired with modern controls for performance monitoring and maintenance optimization.

Whether you need a plug-and-play heat recovery system or a fully customized dual-fluid configuration, Minerza delivers durable, high-efficiency economizers built for long-term industrial use.

ECONOMIZER

SRE Series – Stack-Mounted Condensing Economizer

SRE Series condensing economizers recover latent and sensible heat from flue gas to boost boiler efficiency by up to 10%. With vertical stack-mounted design, stainless steel construction, and full condensing performance, they preheat water for maximum fuel savings in natural gas or propane-fired systems.

ECONOMIZER

ECE Series – Custom Condensing Economizer

ECE Series remote-mounted condensing economizers recover heat from flue gas to boost boiler efficiency by up to 18%. Designed for flexible integration, they handle a variety of fluids and flow rates with custom stainless steel coil configurations, making them ideal for complex or space-restricted systems.

ECONOMIZER

E2X Series – Two-Stage Non-Condensing Economizer

E2X Series non-condensing economizers recover sensible heat in two stages—preheating feedwater and make-up or process water. With dual-material construction and 4–6% efficiency gains, they suit steam systems using natural gas or oil, offering dual-fluid recovery without condensation-related challenges.

ECONOMIZER

E2X-B Series– Two-Stage Non-Condensing Economizer

E2X-B Series two-stage economizers recover sensible heat from flue gases to preheat feedwater and make-up water. With dual metal construction and 4–6% efficiency gain, they suit gas or oil-fired steam boilers needing dual-loop heat recovery without condensation handling.

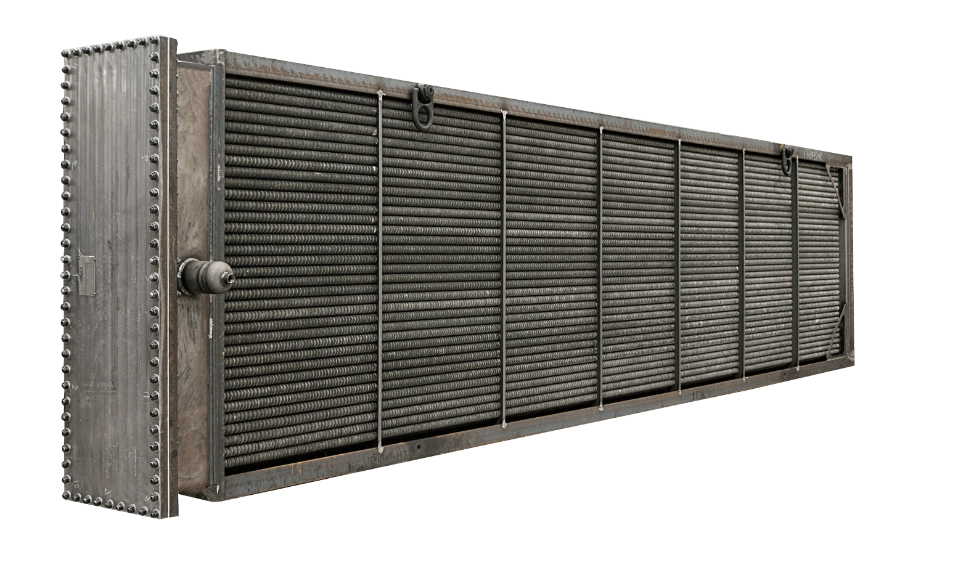

ECONOMIZER

SRB Series – Rectangular Non-Condensing Economizer

SRB Series rectangular economizers recover sensible heat from flue gases to preheat feedwater, improving efficiency by 4–6%. Designed for large firetube or watertube boilers, they offer flexible gas flow orientation, robust materials, and scalable configurations for high-capacity industrial systems.

Air Preheaters

Minerza offers a wide range of industrial air preheaters designed to recover heat from flue gas or steam to preheat combustion air or process air, improving overall boiler efficiency and reducing fuel consumption. Our solutions cover bare tube, finned tube, waterbox header, and ASME-certified designs — with flexible configurations to match new builds or retrofit projects.

Air preheaters help increase thermal performance by raising the temperature of incoming air before it enters the combustion chamber, enabling cleaner combustion, reduced stack losses, and faster boiler response. Units are available in single-row to multi-row layouts, with removable bundles for easy maintenance, and corrosion-resistant coatings such as Heresite for extended service in aggressive environments.

With custom materials (carbon steel, stainless steel, aluminum fins), mounting styles, pressure ratings, and heat transfer surfaces, Minerza preheaters are engineered to meet the specific needs of power plants, process industries, and energy-intensive facilities. All units are built to high manufacturing standards, with optional ASME U-Stamp, airtight headers, and lifting features for safe handling and long service life.

AIR PREHEATER

BTP Series – Bare Tube Steam Coil Air Preheater

BTP Series bare tube preheaters use steam coils to heat incoming air in boiler systems. With 2-row carbon steel tubes, leak-free header, and up to 10 bar steam pressure, they support airflows up to 60 000 Nm³/h and ensure reliable thermal performance, easy duct integration, and long service life.

AIR PREHEATER

WBX Series – Finned Tube Air Preheater with Removable Waterbox Header

WBX Series finned-tube air preheaters feature a removable waterbox header for full tube access, simplifying cleaning and maintenance. With carbon steel core, gusseted structure, and airflow up to 50 000 Nm³/h, they offer durable, high-efficiency preheating for industrial boilers and process systems.

AIR PREHEATER

AUM Series – U-Stamped Spiral Fin Air Preheater

AUM Series U-stamped air preheaters feature carbon steel tubes with aluminum spiral fins, built to ASME Section VIII, Div 1. With 300# flanged connections and full code compliance, they deliver reliable thermal performance and mechanical strength for critical industrial heat recovery systems.

AIR PREHEATER

BTP Series – Bare Tube Steam Coil Air Preheater

BTP Series bare tube preheaters use steam coils to heat incoming air in boiler systems. With 2-row carbon steel tubes, leak-free header, and up to 10 bar steam pressure, they support airflows up to 60 000 Nm³/h and ensure reliable thermal performance, easy duct integration, and long service life.

AIR PREHEATER

HFC Series – Multi-Unit Finned Tube Air Preheater with Heresite Coating

HFC Series preheaters use spiral fin tubes with Heresite-coated cores and housings to resist corrosion in harsh environments. With multi-row design, removable exchangers, and sealed header construction, they deliver long-lasting, efficient air preheating for industrial boiler and ventilation systems.

Heat Exchangers

We offer a complete range of industrial heat exchangers engineered for precise and efficient thermal transfer across a wide variety of process conditions. Our portfolio includes shell & tube, multitube, U-tube, corrugated, and sanitary designs, covering both general-purpose and hygienic applications in the energy, food, chemical, and manufacturing sectors.

From ASME- and TEMA-compliant exchangers for high-pressure industrial systems to 3-A/FDA-certified tubular units for food and pharmaceutical production, every model is optimized for performance, reliability, and cleanability. Available with fixed or removable bundles, single or multi-pass configurations, and materials including carbon steel, stainless steel, duplex, and special alloys, our exchangers meet the most demanding thermal and mechanical specifications.

Whether you require high-efficiency waste heat recovery, sanitary liquid heating and cooling, or compact multi-pass systems for steam and thermal fluids, Minerza delivers custom-engineered heat exchangers with smart construction, easy maintenance, and long service life.

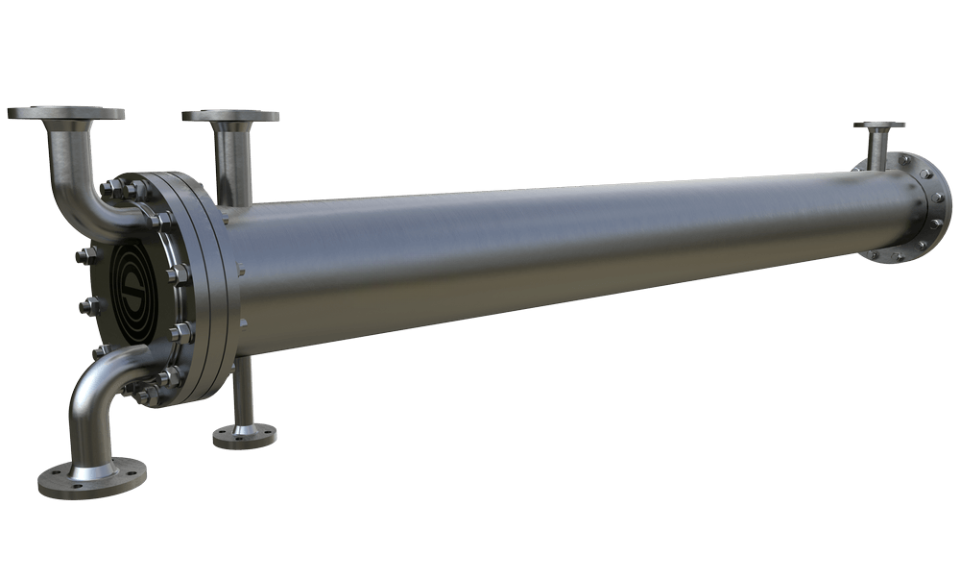

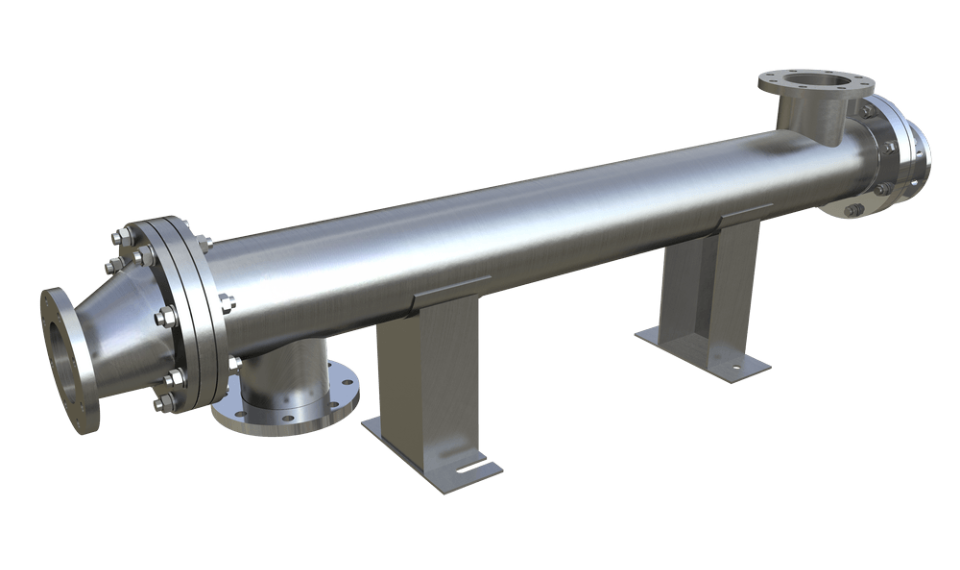

HEAT EXCHANGER

TMX Series – Spec Shell & Tube Heat Exchanger

TMX Series TEMA-type shell & tube heat exchangers are custom-built to ASME/TEMA codes for demanding thermal applications. Available in all TEMA configurations and materials, they support up to 100 bar and 400 °C, with removable bundles, expansion joints, and optimized designs for industrial process heating and cooling.

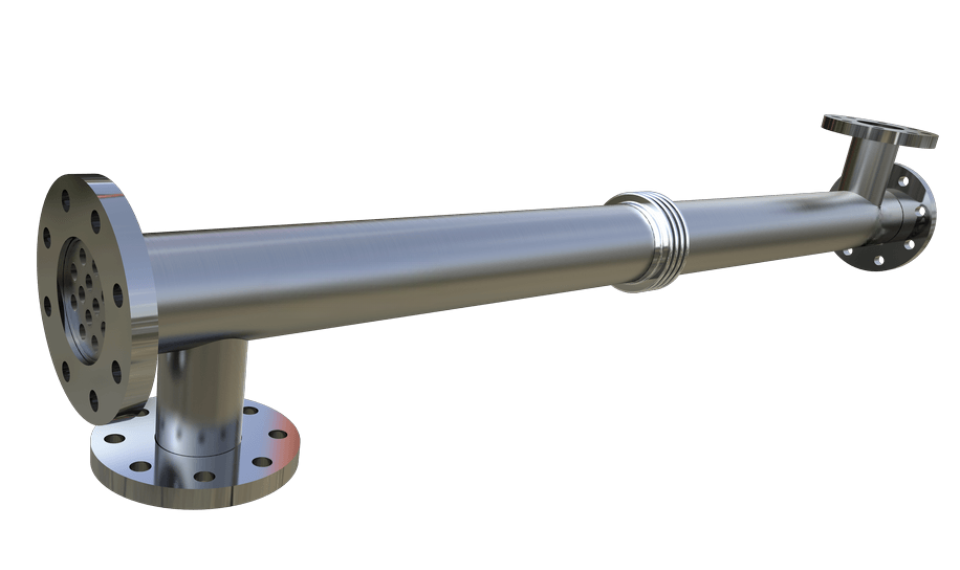

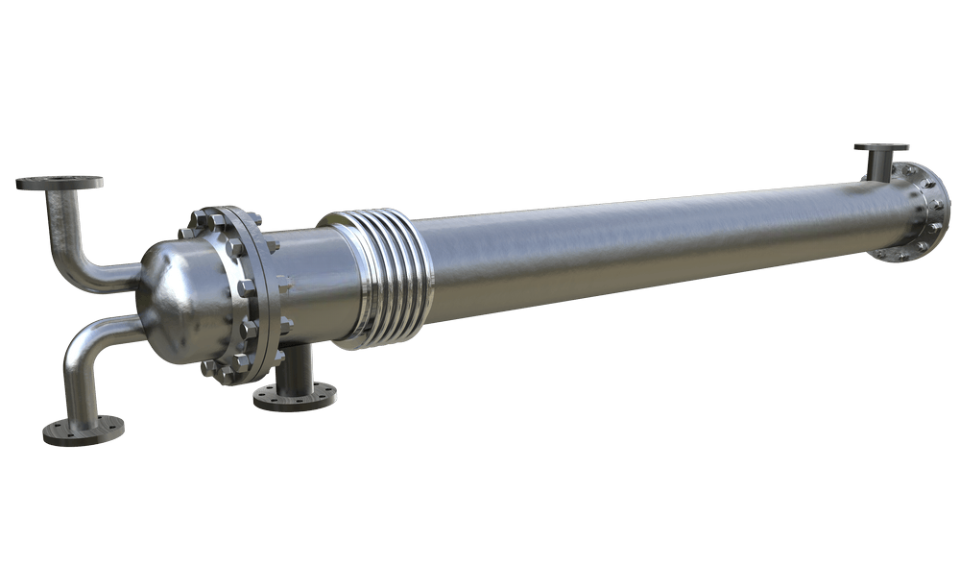

HEAT EXCHANGER

MPX Series – Multi-Pass U-Tube Heat Exchanger

MPX Series shell & tube heat exchangers feature a removable U-tube bundle and multi-pass design for enhanced heat transfer. Built to ASME/TEMA standards, they offer high pressure and temperature tolerance, easy maintenance, and efficient thermal performance for demanding process applications.

HEAT EXCHANGER

VTX Series – Smooth Tube Tubular Heat Exchanger

VTX Series tubular heat exchangers feature hygienic multi-tube design with polished or corrugated tubes for efficient, gentle heating or cooling of food, dairy, and pharma products. FDA and 3-A compliant, they support CIP cleaning, viscous fluids, and sanitary processing under high thermal demand.

HEAT EXCHANGER

MTB Series – Multitube Heat Exchanger with Removable Bundle

MTB Series multitube heat exchangers feature a removable tube bundle for full internal access, ideal for hygienic applications in food, beverage, and pharma. With polished or corrugated tubes, FDA/3-A compliance, and CIP/SIP compatibility, they ensure high-efficiency heat transfer with easy maintenance.

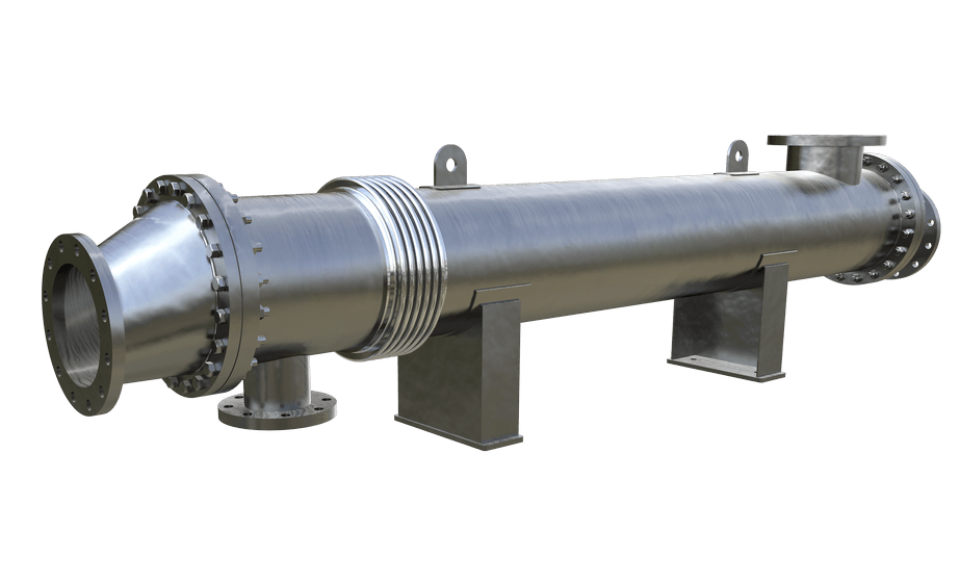

HEAT EXCHANGER

IMP Series – Industrial Multiple-Pass Shell & Tube Heat Exchanger

IMP Series multi-pass shell & tube heat exchangers are built to ASME/TEMA standards for efficient industrial heat transfer. With 2–8 tube passes and customizable design, they handle steam, water, and thermal fluids at high pressures and temperatures, offering robust performance in compact layouts.

HEAT EXCHANGER

MTI Series – Multitube Industrial Heat Exchanger

MTI Series multitube heat exchangers feature a fully welded design for robust thermal performance in industrial water, steam, or oil applications. Ideal for non-hygienic processes, they offer low-maintenance operation, customizable sizing, and high efficiency in compact, durable construction.

Burners

Our company supplies a wide range of industrial and commercial-grade burners designed for high-efficiency, low-emission combustion across various boiler systems and heat applications. Our burner lineup supports natural gas, propane, and light-to-heavy fuel oils, as well as dual-fuel configurations, enabling operational flexibility for both new installations and retrofits.

From ultra-low NOₓ premix surface burners to high-capacity dual-fuel forced-draft systems, our solutions cover input ranges from 2 to 100+ MMBtu/h, with turndown ratios up to 10:1. All burners are fully modulating, with linkage-less controls, low excess air operation, and quiet, stable flame characteristics across varying load conditions.

With mounting options for firetube, watertube, and hybrid boilers, and certified to UL, cUL, CSA, and ASMEstandards, Minerza burners are built for performance, efficiency, and code compliance. Whether the goal is emissions reduction, fuel cost savings, or precise combustion control, our burners deliver proven reliability and seamless integration into modern boiler systems.

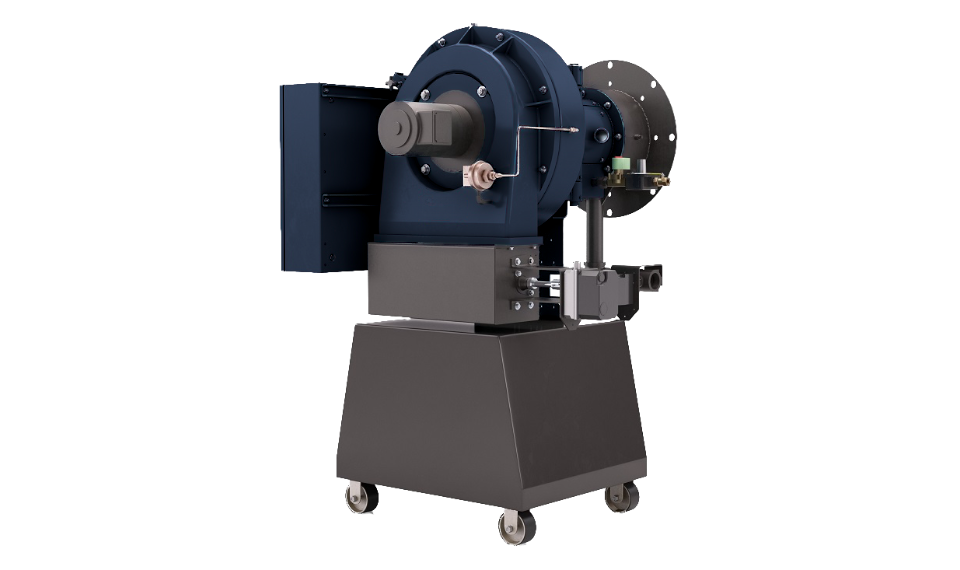

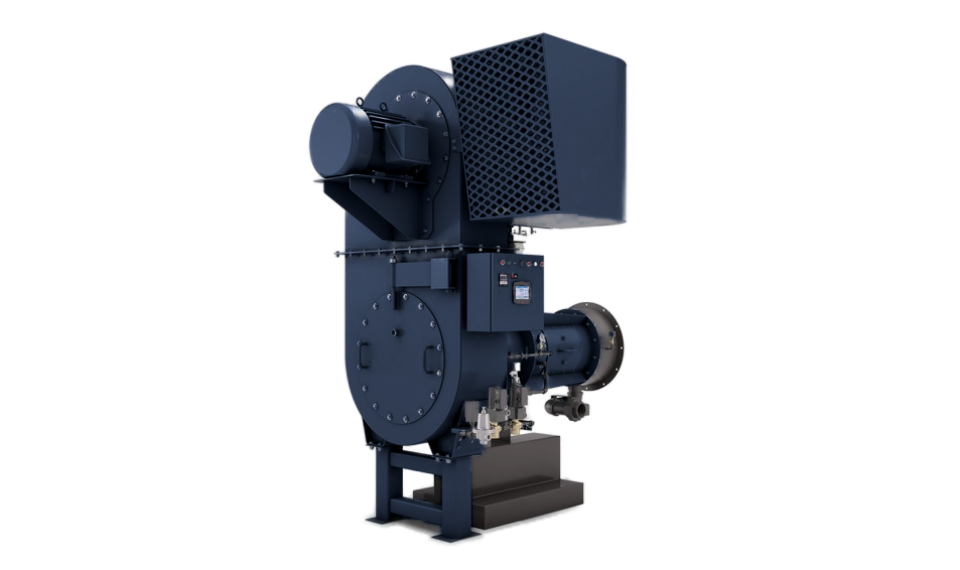

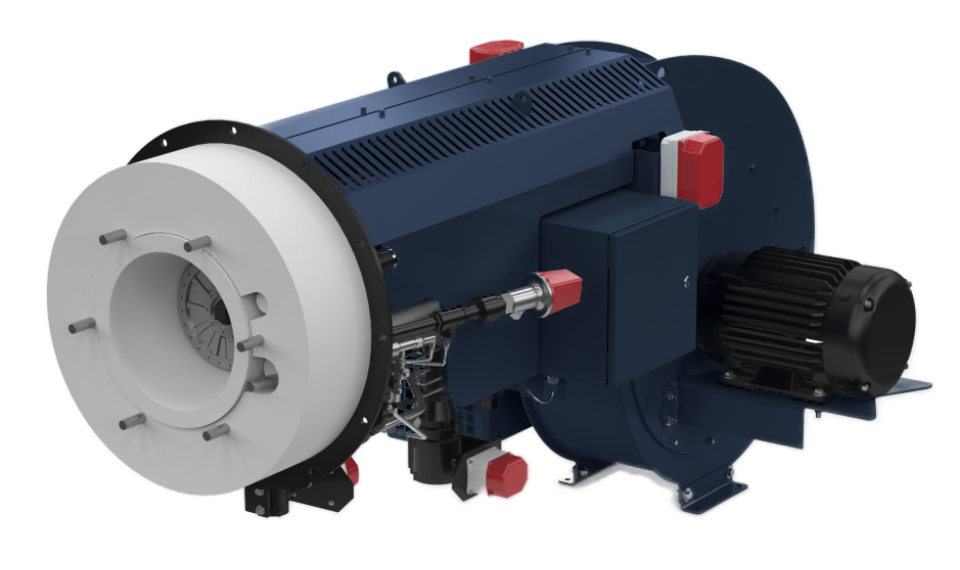

BURNER

DBX Series – Dual-Fuel High-Turndown Burner

DBX Series dual-fuel burners fire gas or oil with 10:1 and 8:1 turndown, offering high efficiency and full modulation for industrial boilers. With low-NOₓ options, high-static blower, and UL listing, they’re ideal for firetube or watertube systems requiring flexible and reliable combustion performance.

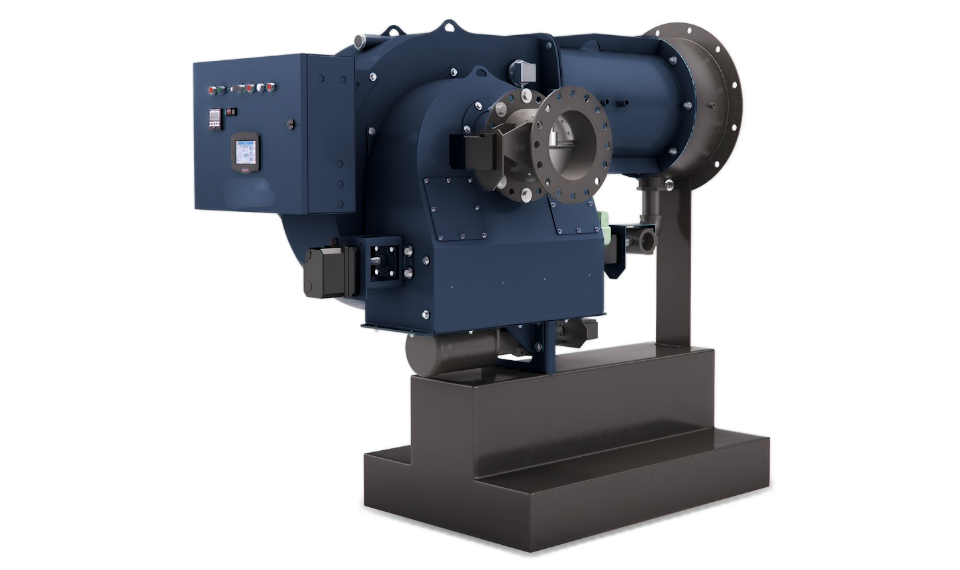

BURNER

XLX Series – High-Capacity Low-NOₓ Industrial Burner

XLX Series burners deliver up to 100.5 MMBtu/h for large industrial boilers. Supporting gas and oil with full modulation and 8:1 turndown, they offer low NOₓ emissions, rugged fans, and UL-certified performance. Ideal for plants needing high-capacity, reliable, and efficient combustion systems.

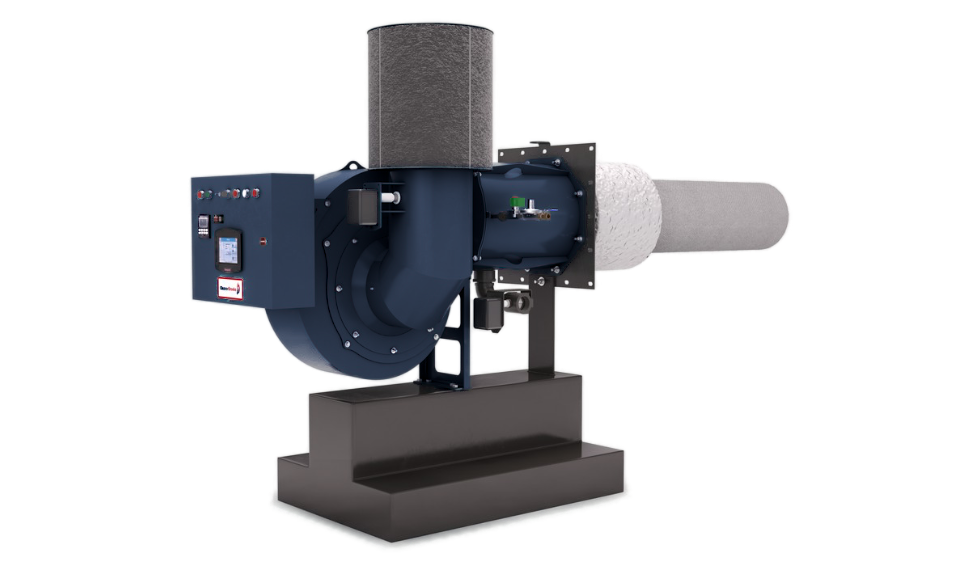

BURNER

EBX Series – Packaged Burner for Steam and Hot Water Boilers

EBX Series burners offer up to 54.6 MMBtu/h with full modulation and 8:1 turndown on gas. Suitable for gas or oil boilers, they ensure efficient, low-NOₓ combustion with integrated fans and flexible control. Ideal for firetube, watertube, or retrofit systems in commercial and light industrial plants.

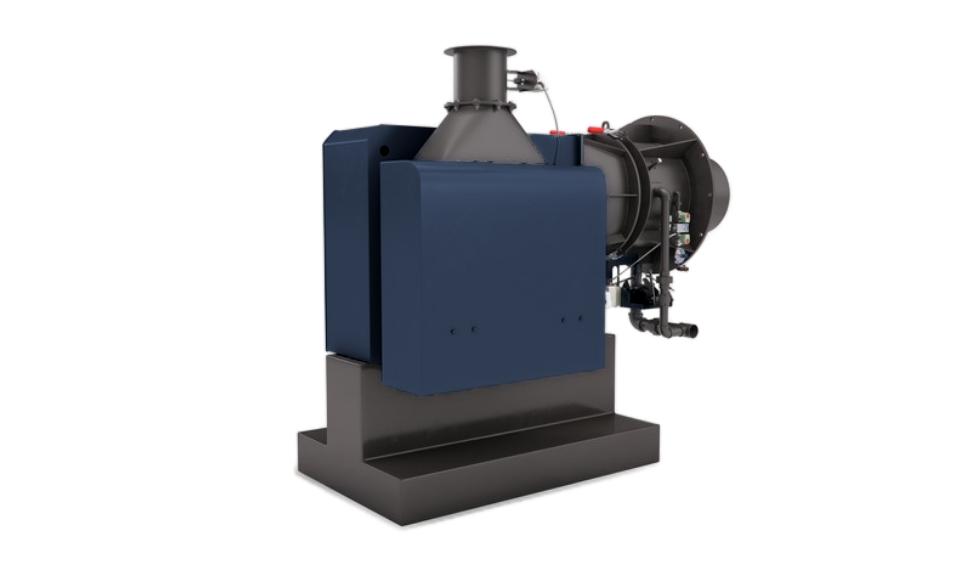

BURNER

MTH Series – High-Turndown, Dual-Fuel Burner for Medium-Pressure Systems

MTH Series burners fire gas or oil with up to 10:1 turndown, delivering efficient, quiet combustion for hot water and low-pressure steam boilers. Compact and fully modulating, they support clean operation with high static fans and are ideal for commercial, institutional, and retrofit boiler systems.

BURNER

S1G Series – Gas-Only Low-NOₓ Burner

S1G Series burners provide clean, gas-only combustion with 10:1 turndown and <30 ppm NOₓ emissions. Fully modulating and compact, they’re ideal for firetube, watertube, and retrofit boilers in commercial or light industrial use—delivering quiet, efficient operation in space-limited environments.

BURNER

SBR Series – Ultra-Low NOₓ Surface Burner

SBR Series ultra-low NOₓ burners use surface-stabilized premix technology to achieve <5 ppm NOₓ without FGR. Designed for natural gas, they deliver quiet, uniform combustion with 3:1 turndown and full modulation. Ideal for firetube and watertube boilers in strict emissions zones or retrofit projects.