EQUIPMENT

Flotation

Machines

At Minerza, we design and supply advanced flotation machines tailored for efficient separation of valuable minerals from gangue. Our solutions are built to perform across all flotation stages — from roughing to cleaning — ensuring high recovery rates, low reagent consumption, and reliable operation in the most demanding conditions.

The AF Series flotation cells use forced-air technology with an advanced rotor–stator system for optimal air dispersion and energy efficiency. These machines are ideal for coarse particle recovery and high-throughput duties.

The GF Series self-aspirated flotation cells operate without blowers, using natural air induction. With low maintenance and compact design, they are well-suited for rougher and scavenger circuits in both greenfield and brownfield plants.

For plants requiring flexibility, the DF Series hybrid cells combine both forced-air and self-aspirated mechanisms in a modular configuration, optimizing performance across a wide range of ore types and particle sizes.

For cleaner stages and fine particle recovery, the VS Series column flotation cells use counter-current washing, a tall slender design, and highly efficient air distribution to maximize grade and minimize entrainment.

All Minerza flotation systems are engineered for reliability, wear resistance, and seamless integration into complex processing circuits — delivering maximum recovery with minimum operational costs.

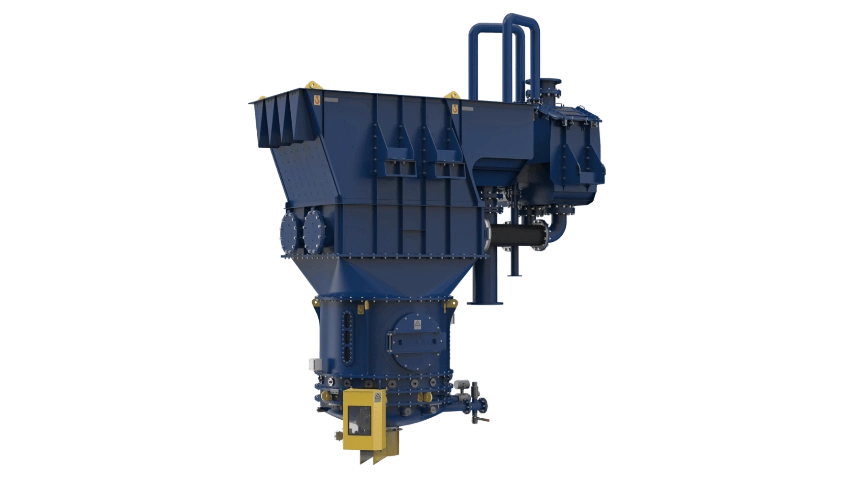

ATTRITION SCRUBBER

AF Series Attrition Scrubbers

Minerza’s AF Series attrition scrubbers deliver high-efficiency slurry cleaning with reverse-pitch impellers and compact tanks. Operating at up to 80% solids, they remove clays and slimes while preserving particle size. Ideal for flotation prep, they offer low wear, easy maintenance, and throughput up to 250 tph.

FLOTATION CELL

RF Series Reflux Flotation Cell

RF Series Reflux Flotation Cell combines lamella separation with intensive gas–solid contact to boost fine particle recovery. Offering >10x feed flux and a 50% smaller footprint, it delivers fast, high-grade flotation with minimal water use—ideal for concentrate polishing and energy-efficient mineral recovery.

FLOTATION CELL

CF Series Column Flotation Cells

CF Series Column Flotation Cells are designed for fine particle recovery and high-grade concentrate production. Featuring a tall, static design with counter-current wash water, they deliver exceptional selectivity, low entrainment, and cleaner froth—ideal for final cleaning and upgrading difficult ores.

FLOTATION CELL

FAF Series Forced-Air Flotation Cells

FAF Series forced-air flotation cells deliver powerful mixing and air dispersion for reliable hydrophobic recovery. Available in standard or hybrid configurations with froth washing, they combine high throughput with reduced entrainment and energy savings—ideal for fine and complex ores.

FLOTATION CELL

CFC Series Coarse Flotation Cells

CFC Series coarse flotation cells recover particles up to 850 μm, cutting overgrinding and energy use. With modular pilot units available for mine-site testing, they integrate easily into operations and deliver real gains in recovery, especially in copper, gold, and phosphate circuits.

Hydrocyclones

We specialize in advanced hydrocyclone solutions designed to meet the demanding needs of modern mineral processing. Hydrocyclones are essential for the efficient classification, separation, dewatering, and desliming of slurry in a wide variety of processing environments — from grinding circuits and cyclone clusters to tailings management and fines recovery systems.

Our hydrocyclones are engineered using cutting-edge computational fluid dynamics (CFD) and manufactured with wear-resistant materials to ensure long service life and low total cost of ownership. The precision of separation they provide helps improve grinding efficiency, increase recovery of valuable minerals, and enhance the performance of downstream equipment such as thickeners, flotation cells, and filters.

Whether operating in extreme abrasion conditions or fine particle classification tasks, Minerza hydrocyclones are designed for consistent performance, reduced turbulence, and high volumetric capacity. They are available in a wide range of sizes and configurations to suit any flow sheet — from single units to large-scale cluster installations.

Each system can be tailored to the specific needs of the process, with options for different cone angles, vortex finder geometries, and liner materials. Our hydrocyclones integrate seamlessly into both greenfield and brownfield plants and are supported by Minerza’s engineering expertise and global service.

When efficiency, reliability, and process control matter most, Minerza hydrocyclones deliver.

HYDROCYCLONES

HX Series High-Efficiency Hydrocyclones

HX Series hydrocyclones by Minerza are engineered for superior fines separation and increased throughput, delivering up to 30% higher capacity without expanding the footprint. With advanced flow control and snap-in liners, they offer longer wear life, lower turbulence, and energy-efficient operation in any classification circuit.

HYDROCYCLONES

CX Series Classification Hydrocyclones

CX Series hydrocyclones are Minerza’s proven solution for reliable classification in demanding conditions. With a compact footprint and high per-unit capacity, they deliver sharp separation, reduced turbulence, and long wear life — ideal for grinding circuits, tailings, and fines recovery across all industries.

HYDROCYCLONES

CT Series Ceramic Hydrocyclones

CT Series hydrocyclones are Minerza’s ceramic-lined solution for high-abrasion applications such as coal, potash, and diamond classification. With spiral inlet geometry, thick alumina tile liners, and robust steel housings, they deliver exceptional separation efficiency and long wear life — even in dense-medium circuits.

HYDROCYCLONES

DM Series Dense-Medium Hydrocyclones

DM Series hydrocyclones are Minerza’s heavy-duty solution for dense-medium separation. Cast entirely from high-chrome white iron, they deliver exceptional wear resistance, sharp separation, and stable operation in coal, potash, and diamond recovery — all without the need for external housing or replaceable liners, reducing maintenance.

HYDROCYCLONES

PU Series Polyurethane Hydrocyclones

PU Series hydrocyclones are Minerza’s lightweight and corrosion-resistant solution for light-duty applications such as desliming and tailings dewatering. Cast in solid polyurethane, they feature spiral laminar inlet geometry for precise separation and operate reliably in clusters or temporary low-wear conditions.

HYDROCYCLONES

DE Series Dual-Stage Hydrocyclones

DE Series hydrocyclones offer a two-stage classification system in one compact unit — improving efficiency in desliming and tailings applications. With no need for intermediate pumping, these cyclones reduce fine bypass and coarse misplacement while enhancing underflow solids and lowering operating costs.

Washes

Plants

At Minerza, our compact sand wash plants are engineered to deliver efficient sand washing performance while ensuring maximum mobility and ease of use. Designed for rapid deployment and simple integration into both greenfield and existing operations, these systems feature a modular skid-mounted layout that reduces installation time and complexity. Every unit is built with wear-resistant materials, including rubber linings at key wear points, ensuring long service life and reduced maintenance.

We offer both single-grade and dual-grade configurations to suit specific production needs. These systems are ideal for processing dry sand or handling sand slurry, making them highly versatile across a range of mining and aggregate operations.

Backed by Minerza’s global service network, our sand wash plants combine reliability, performance, and low total cost of ownership — helping you achieve high-quality results with minimal downtime.

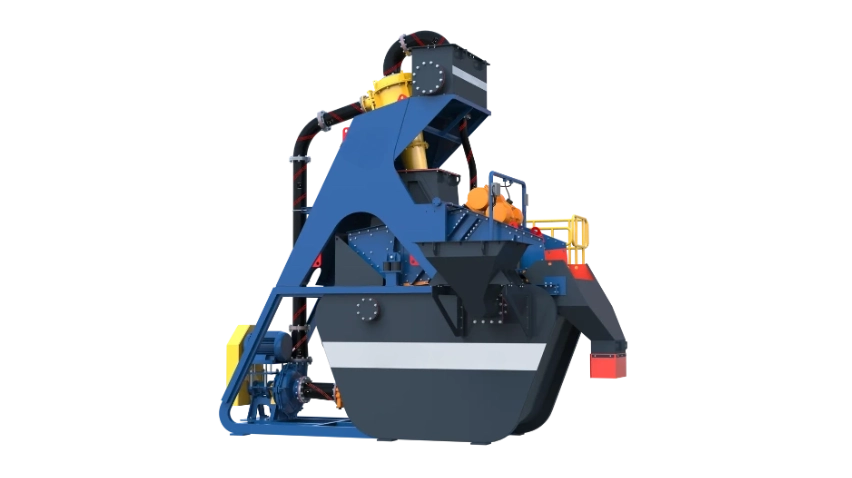

WASHER

SW Series Sand Wash Plants

SW Series Sand Wash Plants from Minerza deliver efficient, low-maintenance sand washing for single-grade output. With a compact, robust design, integrated dewatering screen, and minimal moving parts, these units ensure superior fines recovery and a drier final product — at reduced energy use and cost of ownership.

WASHER

DSW Series Dual-Grade Sand Wash Plants

DSW Series dual-grade sand wash plants by Minerza deliver clean coarse and fine sand in a single pass. With integrated cyclone fines recovery, customizable blending options, and a compact, low-maintenance design, the DSW Series ensures efficient, reliable sand production for demanding operations across mining, construction, and industrial applications.

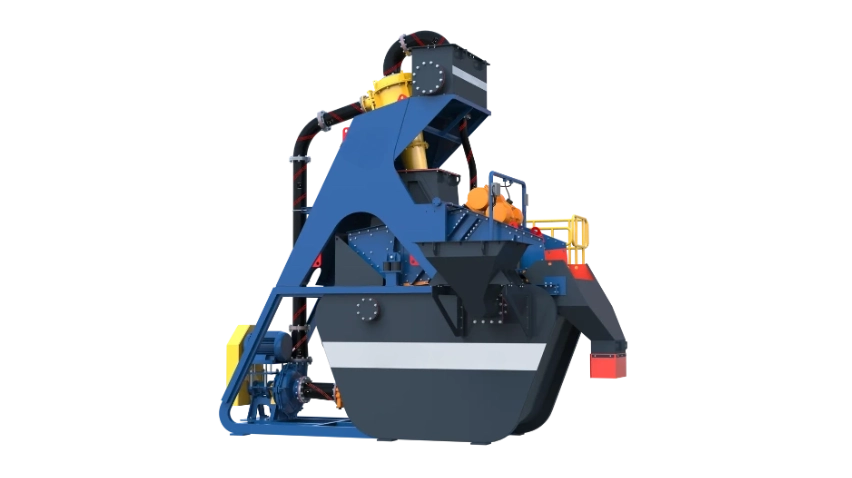

WASHER

SW Series Sand Wash Plants

SW Series Sand Wash Plants from Minerza deliver efficient, low-maintenance sand washing for single-grade output. With a compact, robust design, integrated dewatering screen, and minimal moving parts, these units ensure superior fines recovery and a drier final product — at reduced energy use and cost of ownership.

WASHER

DSW Series Dual-Grade Sand Wash Plants

DSW Series dual-grade sand wash plants by Minerza deliver clean coarse and fine sand in a single pass. With integrated cyclone fines recovery, customizable blending options, and a compact, low-maintenance design, the DSW Series ensures efficient, reliable sand production for demanding operations across mining, construction, and industrial applications.

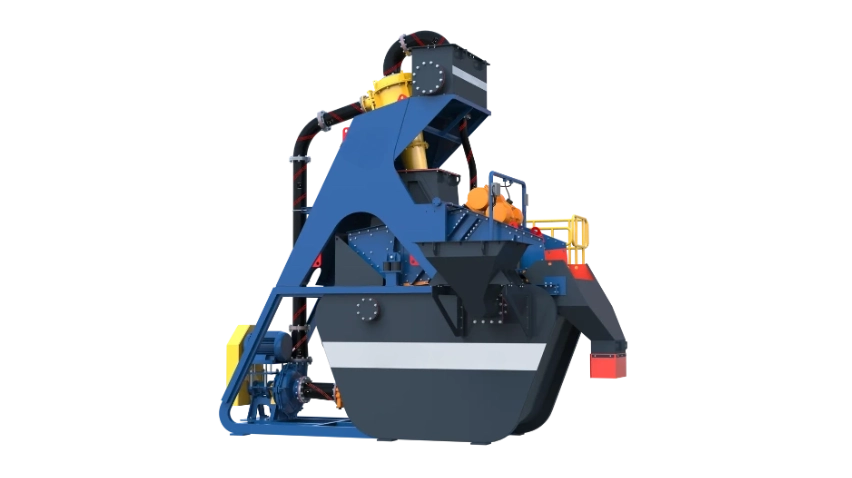

WASHER

SW Series Sand Wash Plants

SW Series Sand Wash Plants from Minerza deliver efficient, low-maintenance sand washing for single-grade output. With a compact, robust design, integrated dewatering screen, and minimal moving parts, these units ensure superior fines recovery and a drier final product — at reduced energy use and cost of ownership.

WASHER

DSW Series Dual-Grade Sand Wash Plants

DSW Series dual-grade sand wash plants by Minerza deliver clean coarse and fine sand in a single pass. With integrated cyclone fines recovery, customizable blending options, and a compact, low-maintenance design, the DSW Series ensures efficient, reliable sand production for demanding operations across mining, construction, and industrial applications.

Classifiers

Our range of classifying solutions is designed to ensure effective material separation and washing across a variety of processing environments. Whether handling coarse aggregates, sand, or scrubbing applications, our equipment delivers reliable performance with minimal maintenance.

We offer solutions such as log classifiers, coarse material classifiers, and sand classifiers (also known as sand screw washers), each tailored for specific particle size ranges and washing intensity. These machines efficiently remove unwanted fines, clays, and contaminants — enhancing product quality and preparing material for downstream processing.

With extensive experience in the sand and aggregate industry, our team provides comprehensive support and equipment selection to help optimize your washing circuit. Whether you’re an established producer or building a new operation, Minerza classifiers are engineered for performance, durability, and ease of integration into your process flow.

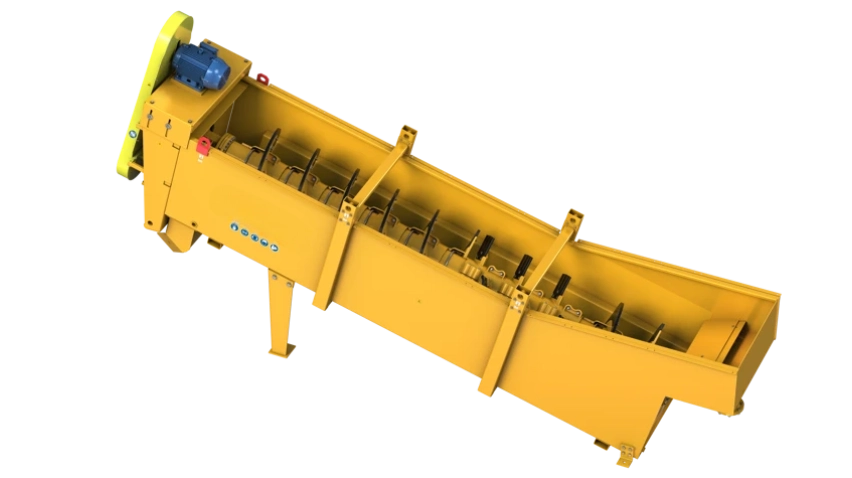

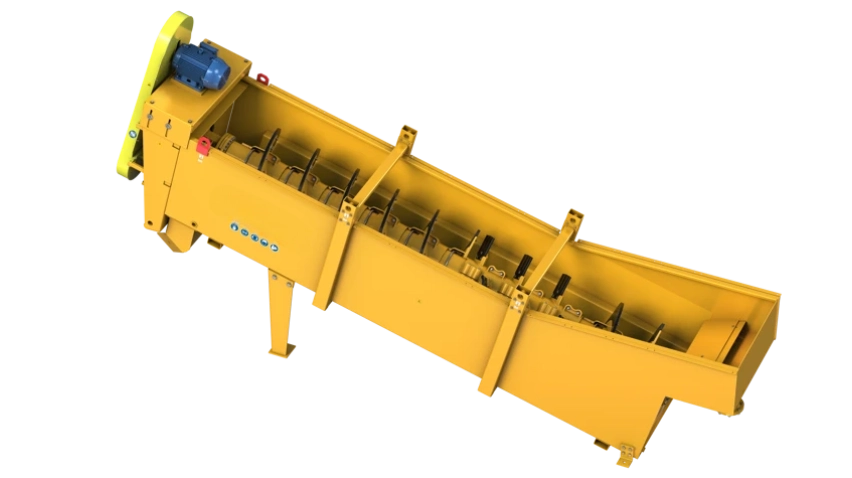

CLASSIFIER

MCW Series Coarse Classifier

MCW Series Classifiers are engineered for washing, classifying, and dewatering coarse materials from 10 to 65 mm. Ideal for removing clays and silts, they offer high torque, low wear, and simple maintenance.

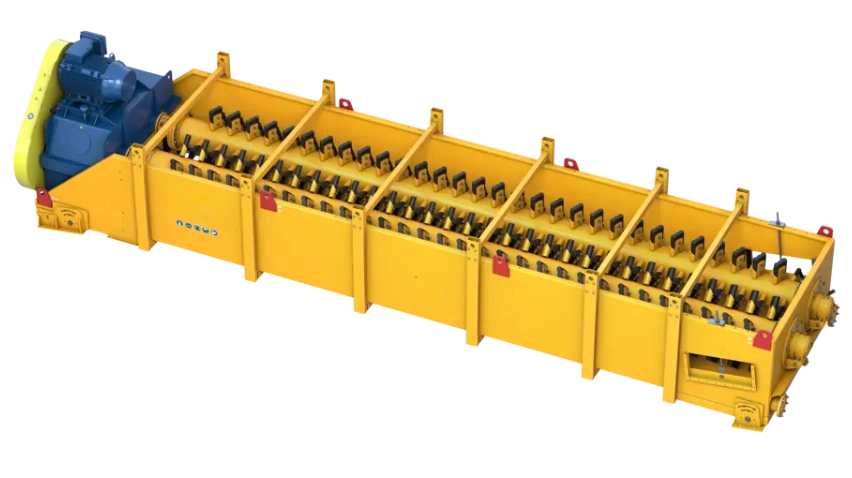

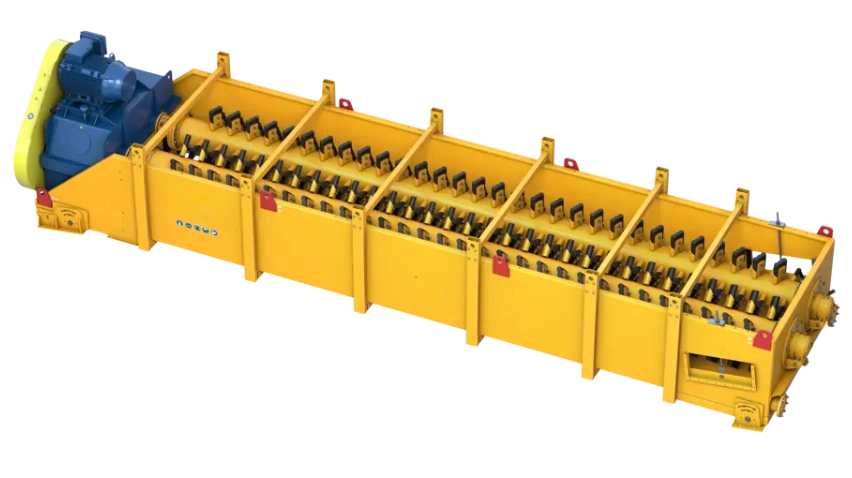

CLASSIFIER

MLW Series Log Classifiers

MLW Series Classifiers are built for intensity scrubbing of clays, conglomerates, and cemented aggregates. With oversized paddles and twin shafts, they deliver maximum cleaning efficiency, extended wear life, and simple service access.

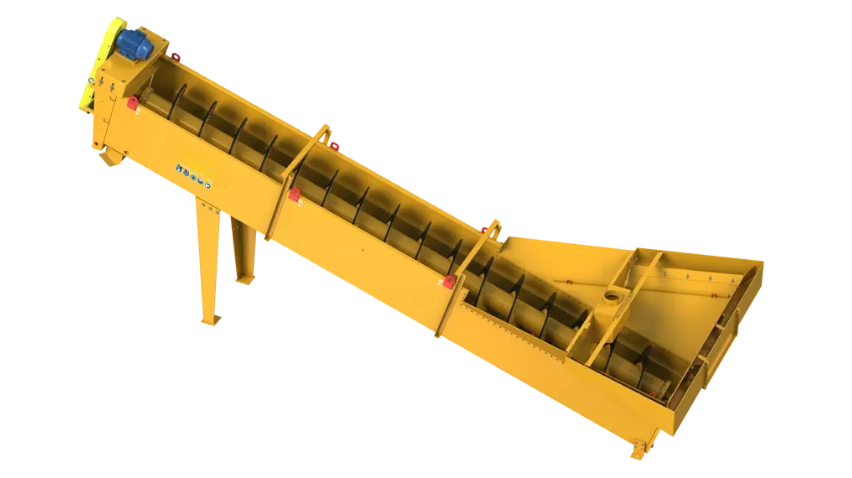

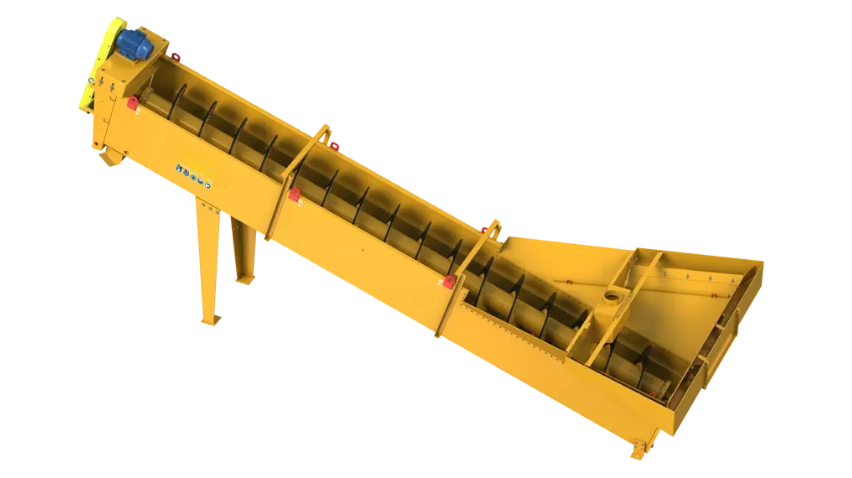

CLASSIFIER

MSW Series Sand Classifiers

MSW Series Sand Classifiers deliver reliable washing and weight-based separation for fine materials. With adjustable spiral speeds and rugged construction, they provide clean, uniform sand for concrete, plaster, and more.

CLASSIFIER

MCW Series Coarse Classifier

MCW Series Classifiers are engineered for washing, classifying, and dewatering coarse materials from 10 to 65 mm. Ideal for removing clays and silts, they offer high torque, low wear, and simple maintenance.

CLASSIFIER

MLW Series Log Classifiers

MLW Series Classifiers are built for intensity scrubbing of clays, conglomerates, and cemented aggregates. With oversized paddles and twin shafts, they deliver maximum cleaning efficiency, extended wear life, and simple service access.

CLASSIFIER

MSW Series Sand Classifiers

MSW Series Sand Classifiers deliver reliable washing and weight-based separation for fine materials. With adjustable spiral speeds and rugged construction, they provide clean, uniform sand for concrete, plaster, and more.

Centrifuges

At Minerza, our centrifuge solutions are designed for highly efficient solid–liquid separation in the most demanding mining and industrial environments. Centrifuges operate on the principle of centrifugal force to rapidly separate solids from slurry, providing fast and continuous dewatering while reducing the need for chemical flocculants or additional filtration stages.

We offer a comprehensive range of solid-bowl centrifuges engineered with wear-resistant components, robust mechanical design, and precision balancing for long-term reliability. These systems are ideal for applications such as coal preparation, tailings management, and mineral concentrate dewatering. Our centrifuges handle variable feed conditions while maintaining high solids recovery and low moisture in the discharged cake.

In coal washing circuits, our industry-leading wedge wire centrifuge baskets deliver exceptional durability and classification performance. These baskets are optimized for particle retention, drainage efficiency, and reduced vibration — ensuring minimal maintenance and high throughput even in abrasive environments.

Minerza centrifuges can be integrated into automated dewatering systems, and are available in a variety of sizes and configurations to suit specific flow rates, particle sizes, and process conditions. With a focus on reliability, energy efficiency, and serviceability, our centrifuges support sustainable water recovery and reduced tailings volume across diverse industries.

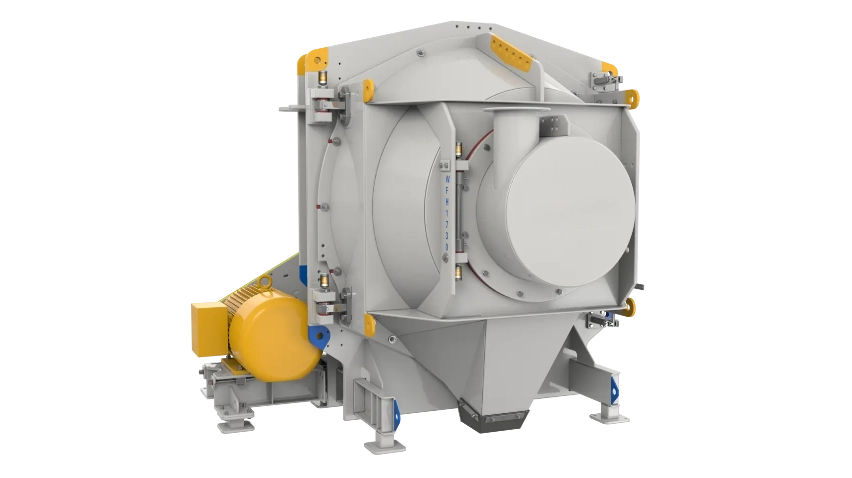

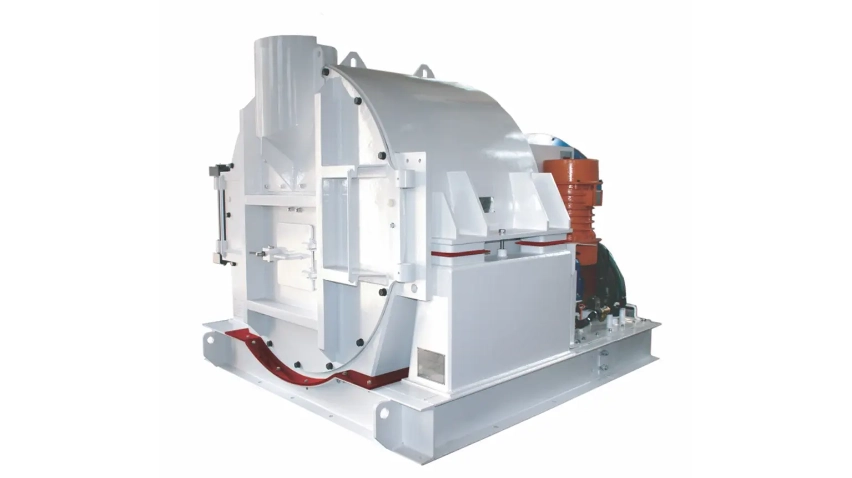

CENTRIFUGE

CC Series Coarse Coal Centrifuge

Minerza’s CC Series centrifuges deliver efficient dewatering of coarse coal with low product moisture and high capacity. Featuring wear-resistant materials, a precision wedge wire basket, and easy maintenance access, they ensure reliable operation, minimal downtime, and seamless integration into existing coal circuits.

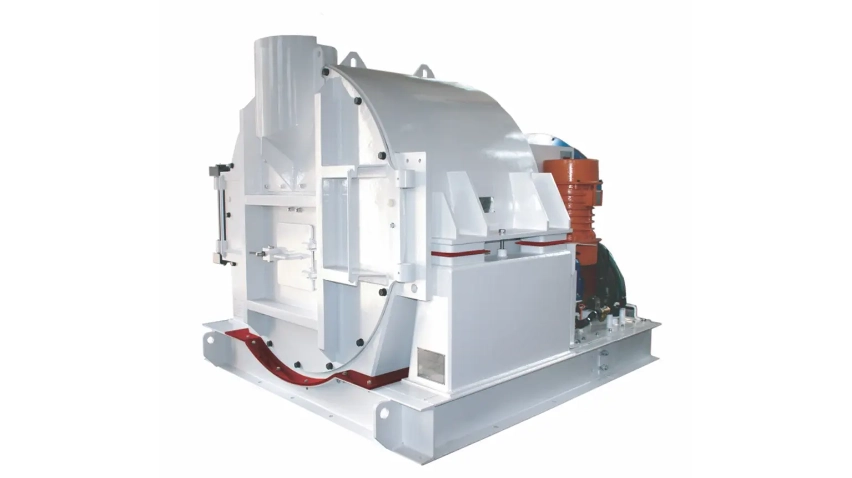

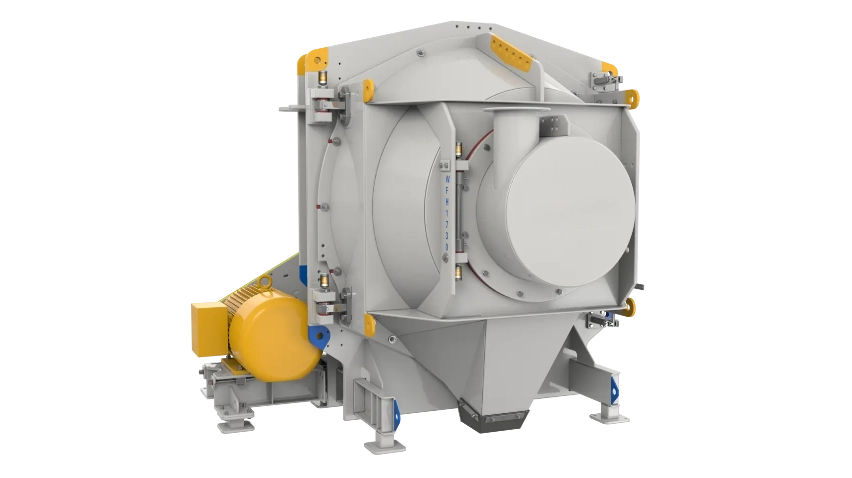

CENTRIFUGE

FCN Series Horizontal Fine Coal Centrifuge

FCN Series centrifuges deliver high-capacity fine coal dewatering with consistently low product moisture, simplified access for maintenance, robust construction, extended wear life, and excellent operational efficiency — all within a compact, retrofit-friendly footprint fully compatible with most existing installations and process layouts.

CENTRIFUGE

FCX Series Decanter Centrifuges

FCX Series decanter centrifuges deliver continuous, high-efficiency dewatering of ultrafine tailings with automated control, excellent wear resistance, and low maintenance requirements. Designed for high-throughput and remote operations, they handle challenging slurries while ensuring reduced downtime and consistent dryness levels.

CENTRIFUGE

CC Series Coarse Coal Centrifuge

Minerza’s CC Series centrifuges deliver efficient dewatering of coarse coal with low product moisture and high capacity. Featuring wear-resistant materials, a precision wedge wire basket, and easy maintenance access, they ensure reliable operation, minimal downtime, and seamless integration into existing coal circuits.

CENTRIFUGE

FCN Series Horizontal Fine Coal Centrifuge

FCN Series centrifuges deliver high-capacity fine coal dewatering with consistently low product moisture, simplified access for maintenance, robust construction, extended wear life, and excellent operational efficiency — all within a compact, retrofit-friendly footprint fully compatible with most existing installations and process layouts.

CENTRIFUGE

FCX Series Decanter Centrifuges

FCX Series decanter centrifuges deliver continuous, high-efficiency dewatering of ultrafine tailings with automated control, excellent wear resistance, and low maintenance requirements. Designed for high-throughput and remote operations, they handle challenging slurries while ensuring reduced downtime and consistent dryness levels.

Vibratory Screens

At Minerza, we design and manufacture a diverse range of screen types tailored to meet specific operational needs. Whether your goal is efficient classification, high-volume processing, or enhanced moisture control, our screening solutions deliver outstanding performance across every application.

• Dewatering Screens. Our dewatering screens feature an upward-sloping deck that forces material to move against gravity, significantly slowing its travel across the screen surface. This design results in highly efficient moisture removal and delivers a consistently drier final product. Built with robust materials and proven engineering, our dewatering screens ensure durability and optimal performance in demanding environments.

• Horizontal Screens. Horizontal screens are engineered for applications requiring longer material retention on the screening surface. With no deck inclination, linear motion drives material forward, increasing the time it remains in contact with the screen media. This extended exposure enhances separation efficiency, making horizontal screens ideal for applications where accuracy and throughput must go hand in hand.

• Banana Screens. Banana screens combine the high-capacity characteristics of inclined screens with the accuracy of horizontal designs. Named for their curved profile, these multi-slope screens feature a steep feed angle (typically 25–35°) that promotes high flow rates at the feed end, gradually transitioning to a flatter discharge zone for improved material stratification and separation. This hybrid configuration makes banana screens highly effective for processing large volumes without compromising precision.

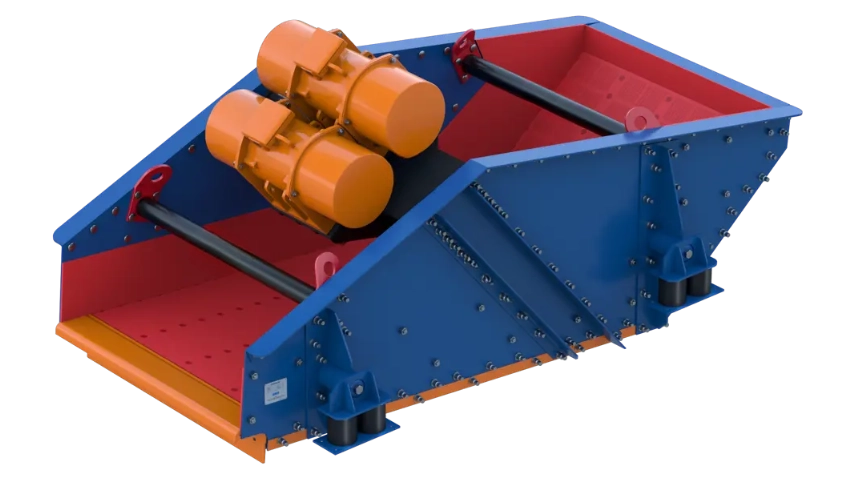

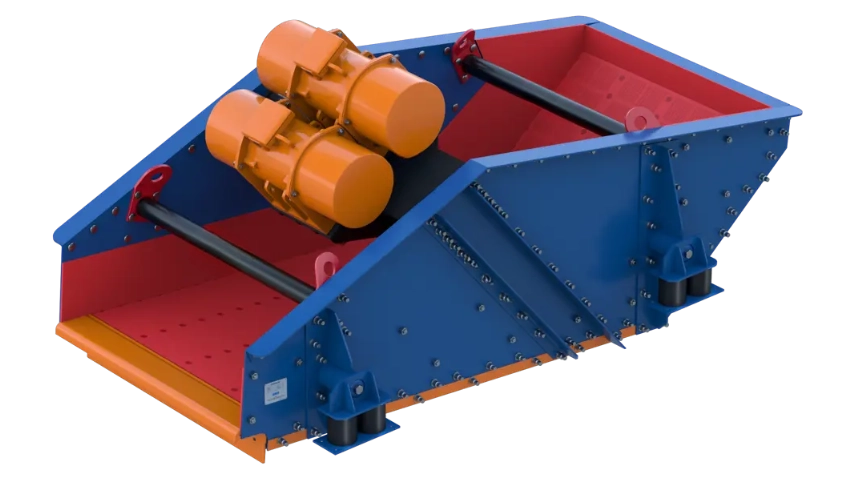

HORIZONTAL SCREEN

EHS Series Horizontal Screen

EHS Series horizontal screens deliver exceptional screening performance and reliability for both wet and dry applications. With custom dimensions up to 4.27 m wide and 10 m long, they feature robust all-bolted construction, advanced corrosion protection, and premium wear-resistant linings

DEWATERING SCREEN

EDS Series Dewatering Screen

EDS Series dewatering screens are engineered for high-capacity water removal and fine material recovery. With inclined design and modular screen panels, they deliver efficient drainage, easy maintenance, and exceptional performance in sand, aggregate, and mining operations — even in the toughest wet conditions

BANANA SCREEN

EBS Series Banana Screen

EBS Series banana screens are high-capacity, multi-slope vibrating screens ideal for dry and wet classification. With exceptional stratification and throughput performance, they are built for precise sizing at high volumes. Equipped with Weir’s ETX exciters and Minatex® rubber, they ensure durability and simplified maintenance in harsh mining environments.

HORIZONTAL SCREEN

EHS Series Horizontal Screen

EHS Series horizontal screens deliver exceptional screening performance and reliability for both wet and dry applications. With custom dimensions up to 4.27 m wide and 10 m long, they feature robust all-bolted construction, advanced corrosion protection, and premium wear-resistant linings

DEWATERING SCREEN

EDS Series Dewatering Screen

EDS Series dewatering screens are engineered for high-capacity water removal and fine material recovery. With inclined design and modular screen panels, they deliver efficient drainage, easy maintenance, and exceptional performance in sand, aggregate, and mining operations — even in the toughest wet conditions

BANANA SCREEN

EBS Series Banana Screen

EBS Series banana screens are high-capacity, multi-slope vibrating screens ideal for dry and wet classification. With exceptional stratification and throughput performance, they are built for precise sizing at high volumes. Equipped with Weir’s ETX exciters and Minatex® rubber, they ensure durability and simplified maintenance in harsh mining environments.